Blueberry healthcare baijiu product

A technology for health care wine and blueberry, which is applied in the preparation of alcoholic beverages, microorganisms, biochemical equipment and methods, etc., to achieve the effect of simple process, easy operation and lower alcohol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Select 200kg of selenium-enriched blueberry raw materials without rot, wash them, air-dry them at 45-55° C., control the water content of the blueberries at 30-40%, mash the blueberries, and beat them to obtain blueberry pulp. Take 150L of blueberry pulp, add 300L of 70% ethanol aqueous solution, adjust the pH value to 4 with 0.1mol / L hydrochloric acid, ultrasonically extract for 40 hours, filter with 2 layers of gauze, repeat twice, combine the filtrate, and obtain the blueberry pomace for later use. The obtained filtrate was concentrated under reduced pressure below 50°C to 1 / 30 of the original volume, adsorbed on XDA-8 macroporous resin, carried out gradient elution with 12BV of 40-80% ethanol aqueous solution, collected the eluate, and washed The deliquored liquid was concentrated to dryness under reduced pressure below 50°C to obtain blueberry pigment.

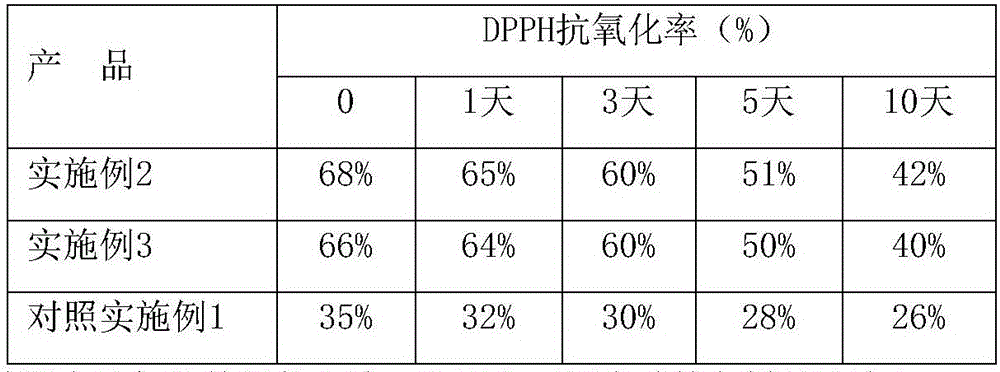

Embodiment 2

[0036] Mix 100kg of blueberry pomace with 20kg of bean cake powder, add 120kg of water, put it into a fermenter, sterilize at 100-110°C for 20 minutes, cool to room temperature and then add 25kg of Mucor seed solution, the fermentation time is 3 days, and then Add 1.5 kg of pectinase and stir evenly, adjust the pH to 4.5, and perform enzymatic hydrolysis for 3 hours to obtain an enzymatic hydrolysis solution. Take 200L of enzymolysis solution and add 20kg of sucrose and 15kg of distiller's yeast, stir evenly, seal and carry out anaerobic fermentation, the temperature is controlled at 28°C, and the fermentation time is 30 days. The fermented liquid is filtered twice with three layers of gauze, and then filtered through a ceramic membrane once to obtain the blueberry pomace fermented liquid. Get 5kg of blueberry pomace fermented liquid, 0.8kg of water, 3kg of sorghum wine, 1.2kg of blueberry pigment, 40g of sodium carboxymethylcellulose and mix evenly to obtain blueberry health ...

Embodiment 3

[0038] Mix 200kg of blueberry pomace with 40kg of bean cake powder or peanut cake powder, add 240kg of water, put it into a fermenter, sterilize at 100-110°C for 30 minutes, cool to room temperature, and then add 48kg of Mucor seed solution. The fermentation time is After 4 days, 3 kg of pectinase was added to stir evenly, the pH was adjusted to 5, and the enzyme hydrolyzed for 3 hours to obtain an enzymatic hydrolyzate. Take 300L of enzymolysis solution and add 40kg of sucrose and 25kg of distiller's yeast, stir evenly, seal and carry out anaerobic fermentation, the temperature is controlled at 28°C, and the fermentation time is 30 days. The fermented liquid is filtered twice with three layers of gauze, and then filtered through a ceramic membrane once to obtain the blueberry pomace fermented liquid. Get 120kg of blueberry pomace fermented liquid, 15kg of water, 60kg of miscellaneous grain wine, 30kg of blueberry pigment, 0.8kg of sodium carboxymethyl cellulose and mix unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com