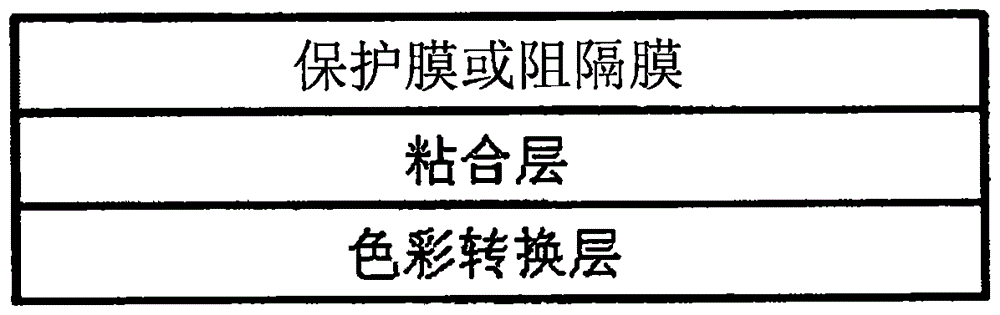

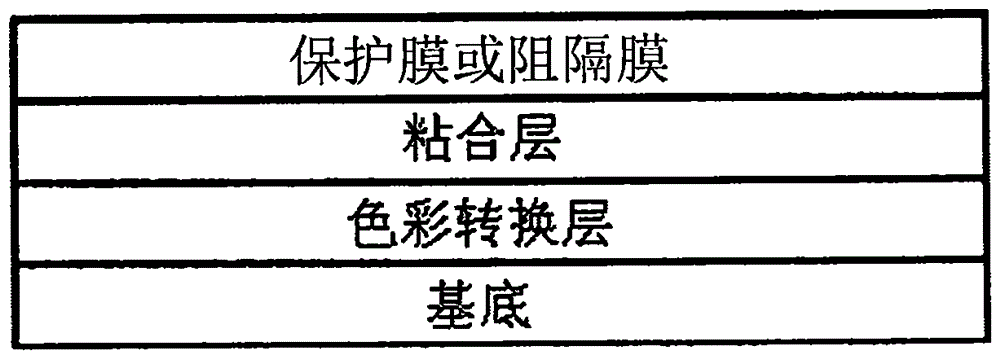

Color conversion film and back light unit and display apparatus comprising the same

A technology of color conversion and green light, applied in optical components, film/sheet adhesives, optics, etc., can solve problems such as rising interest, and achieve the effect of preventing the deterioration of optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Based on 100 parts by weight of the composition, it will include 97 parts by weight of poly(ethylene glycol) diacrylate (free radical polymerizable polymer with a molecular weight of 300-400), and 3 parts by weight of a photoinitiator with the following structural formula The composition (100 parts by weight) of (Irgacure 819) is applied on the color conversion layer (based on the resin of 100 parts by weight, the organic fluorescent substance is 0.2 parts by weight) comprising the resin matrix and the organic fluorescent substance of the following structural formula, and the PET film attached thereto, and the resultant was cured by UV radiation.

[0090]

[0091] Using the color conversion film prepared as above, Figure 6 It is shown that the light emitted from the blue LED backlight with the maximum light emission wavelength in the range of 440nm-460nm is irradiated to the entire color conversion film prepared as above using a light guide plate at 60°C, under 60°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com