Environment-friendly water-based ink

A water-based ink, environmentally friendly technology, applied in the direction of ink, household appliances, applications, etc., can solve the problems affecting the appearance of packaging products, pollution of production equipment, single function, etc., to achieve excellent adhesion, long storage time, and solve the effect of storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

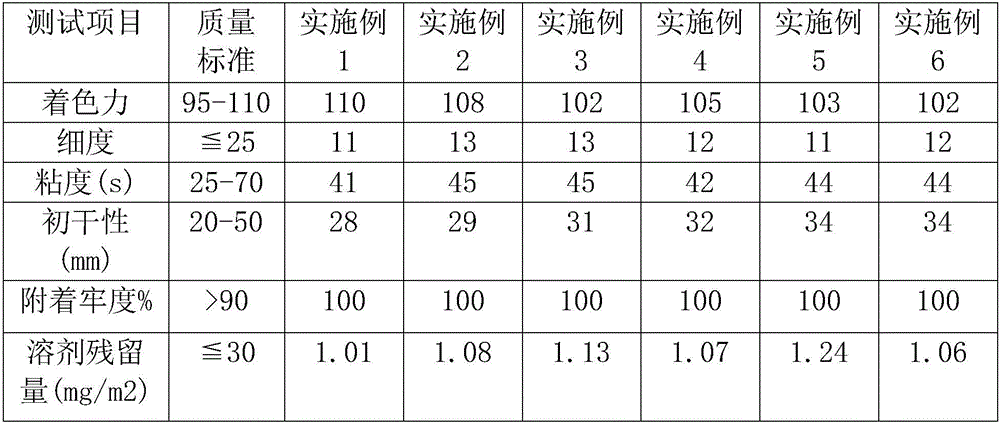

Examples

preparation example Construction

[0034] Preparation of waterborne polyurethane binder:

[0035] (1) Raw material pretreatment: firstly polyadipate sebacic acid neopentyl glycol-1,6-hexanediol ester diol is decompressed and dehydrated for 1 hour at 100° C. and 0.1 MPa vacuum, and the poly The number-average molecular weight of adipate sebacate neopentyl glycol-1,6-hexanediol ester diol is 2000, and diphenylmethane diisocyanate is dehydrated and dried with activated molecular sieves;

[0036] (2) Preparation of prepolymer: 35 parts by weight of polyadipate sebacate neopentyl glycol-1,6-hexanediol ester diol is added in the flask, the flask is equipped with a stirrer, condenser , a thermometer and a ventilation tube, feed dry argon into the reaction system, then start the stirrer, add 30 parts by weight of 2,2-dimethylol butanoic acid, then add 3 parts by weight of diphenylmethane diisocyanate and 0.01 parts by weight of bismuth laurate, slowly warming up to 80°C, and reacting at a constant temperature for 2 ho...

Embodiment 1

[0041] 35 parts by weight of waterborne polyurethane;

[0042] 10 parts by weight of polypropylene emulsion;

[0043] 1 part by weight of polyamide wax;

[0044] 0.5 parts by weight of sodium polyacrylate;

[0045] 0.2 parts by weight of hydroxymethylcellulose;

[0046] 0.2 parts by weight of octylphenol polyoxyethylene ether;

[0047] 0.5 parts by weight of sodium alkylsulfonate;

[0048] 10 parts by weight of pigment;

[0049] 10 parts by weight of water;

[0050] 5 parts by weight of ethyl acetate;

[0051] 0.3 parts by weight of oregano oil;

[0052] Litsea cubeba essential oil 0.2 parts by weight;

[0053] Cinnamon essential oil 0.1 part by weight.

Embodiment 2

[0055] 40 parts by weight of waterborne polyurethane;

[0056] 20 parts by weight of polypropylene emulsion;

[0057] 3 parts by weight of polyamide wax;

[0058] 1 part by weight of sodium polyacrylate;

[0059] 1 part by weight of hydroxymethyl cellulose;

[0060] 0.8 parts by weight of octylphenol polyoxyethylene ether;

[0061] 1.5 parts by weight of sodium alkylsulfonate;

[0062] 20 parts by weight of pigment;

[0063] 20 parts by weight of water;

[0064] 15 parts by weight of ethyl acetate;

[0065] 0.4 parts by weight of oregano oil;

[0066] Litsea cubeba essential oil 0.3 parts by weight;

[0067] Cinnamon essential oil 0.2 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com