Method for synthesizing ketone compounds by continuous cyclic catalytic reaction

A ketone compound and catalytic reaction technology, which is applied in the field of continuous cycle catalytic reaction to synthesize ketone compounds, can solve the problems of insurmountability, long reaction cycle, high reaction equipment, etc., and achieve the goal of reducing loss, shortening synthesis reaction time and improving catalytic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

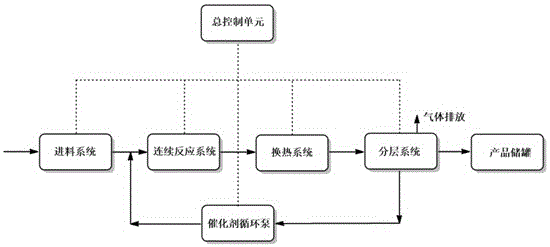

[0040] see figure 1

[0041] 1. Parameter setting and input: Input various values of reaction temperature, reaction time, reaction pressure, heat exchange temperature and pressure, opening and closing time of pressure control valve and catalyst discharge valve, liquid flow rate value of flow rate controller into the inside the console;

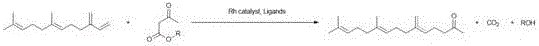

[0042] 2. Input of raw material liquid and catalyst: feed the farnesene raw material liquid with a content of 97% through the liquid inlet pipe through the advection pump, and set the flow rate by the flow rate controller. The liquid enters at a flow rate of 0.4L / min, and the content is 95 The raw material liquid of % methyl acetoacetate passes through the advection pump through the liquid inlet pipe, and the flow rate is set by the flow rate controller. , triphenylphosphine trisulphonic acid sodium salt, water and methanol, the catalyst raw material liquid is passed through the advection pump through the catalyst liquid inlet pipe, and th...

Embodiment 2

[0051] see figure 1

[0052] 1. Parameter setting and input: Input various values of reaction temperature, reaction pressure, heat exchange temperature and pressure, opening and closing time of pressure control valve and catalyst discharge valve, liquid flow rate value of flow rate controller into the operation console ;

[0053] 2. Input of raw material liquid and catalyst: feed the farnesene raw material liquid with a content of 95% through the liquid inlet pipe through the advection pump, and set the flow rate by the flow rate controller. The raw material liquid of ethyl acetoacetate is passed through the advection pump through the liquid inlet pipe, and the flow rate is set by the flow rate controller. The catalyst raw material liquid composed of phosphine bis-sulfonic acid sodium salt, water and ethanol is passed through the catalyst inlet pipe through the advection pump, and the flow rate is set by the flow rate controller. The liquid enters at a flow rate of 1.7L / mi...

Embodiment 3

[0062] see figure 1

[0063] 1. Parameter setting and input: Input various values of reaction temperature, reaction pressure, heat exchange temperature and pressure, opening and closing time of pressure control valve and catalyst discharge valve, liquid flow rate value of flow rate controller into the operation console ;

[0064] 2. Input of raw material liquid and catalyst: feed the farnesene raw material liquid with a content of 98% through the liquid inlet pipe through the advection pump, and set the flow rate by the flow rate controller. The liquid enters at a flow rate of 0.7 L / min, and the content is 98 The % propyl acetoacetate raw material liquid is passed through the advection pump through the liquid inlet pipe, and the flow velocity is set by the flow velocity controller. The catalyst raw material liquid composed of phenylphosphine monoisosulfonic acid sodium salt, water and propanol is passed through the advection pump through the catalyst liquid inlet pipe, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com