One-piece wheel and manufacturing method thereof

A manufacturing method and integrated technology, applied in wheel manufacturing, spoked wheels, wheels, etc., can solve the problems of complex tire manufacturing process, and achieve the effect of improving high-speed performance, reducing costs, and reducing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

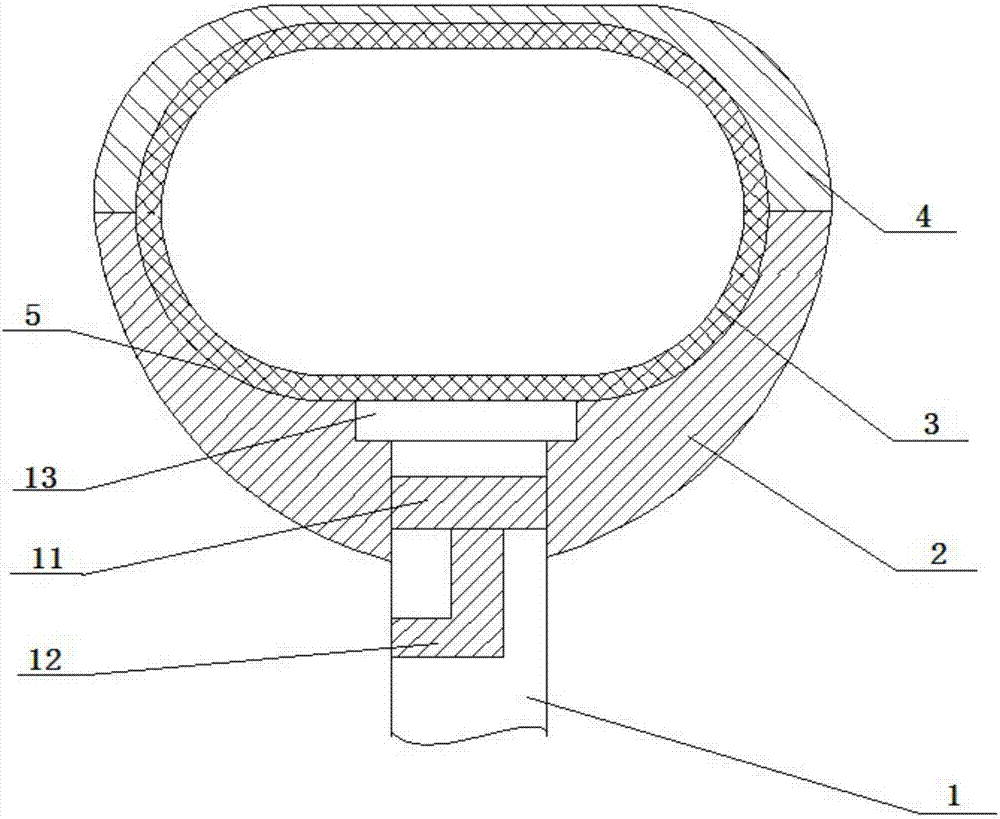

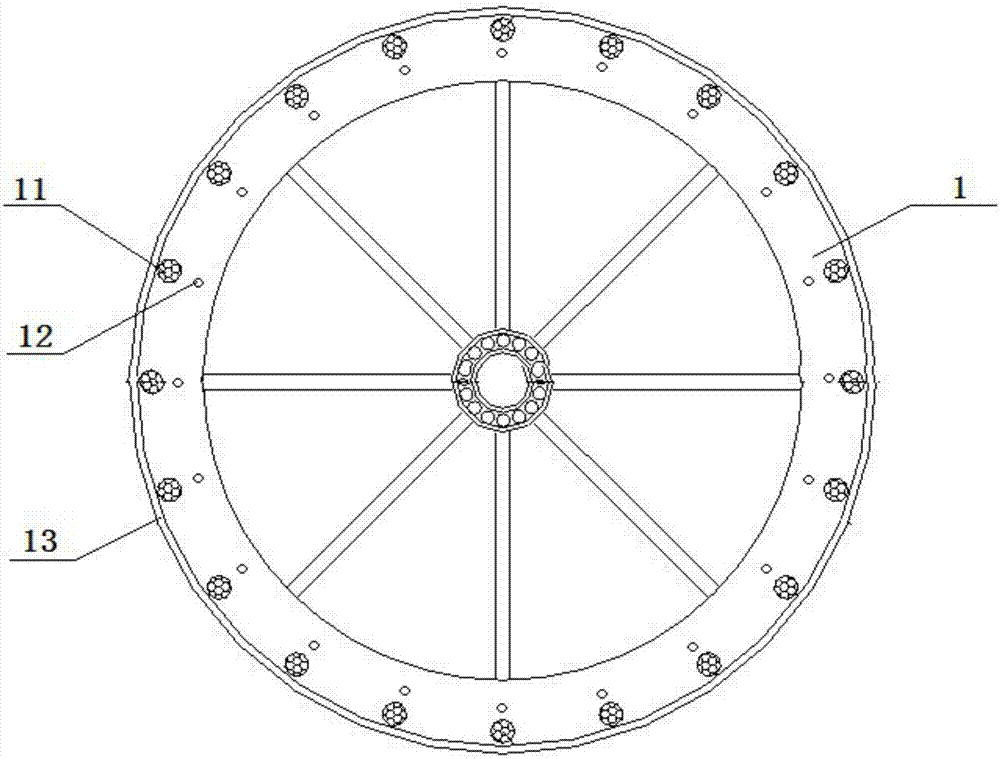

[0032] The one-piece wheel, as shown in the figure, includes a rim 1 and a tread 4, a connecting layer 2 is attached to the outer ring of the rim 1, and an annular hollow tube 3 coaxial with the rim 1, and the annular hollow tube 3 is installed through the connecting layer 2 On the rim 1 a tread 4 is laid on the outside of the annular hollow tube 3 . The outer ring of the rim 1 is provided with an annular mounting rib 13, and the connecting layer 2 is attached to the mounting rib 13 to form a split ring 5 that opens outward. Pipe wall fit.

[0033] The tread 4 is an annular surface, the tread 4 is connected to the opening of the split ring 5 and forms an annular cavity matched with the annular hollow tube 3, and the annular hollow tube 3 is installed in the annular cavity formed by the split ring 5 and the tread 4 .

[0034] Small holes 11 are evenly distributed on the rim 1 , and the axial direction of the small holes 11 is parallel to the axial direction of the rim 1 . The...

Embodiment 2

[0045] With embodiment 1, difference is the manufacture method of making integrated wheel,

[0046] The manufacturing method of the integrated wheel comprises the following steps:

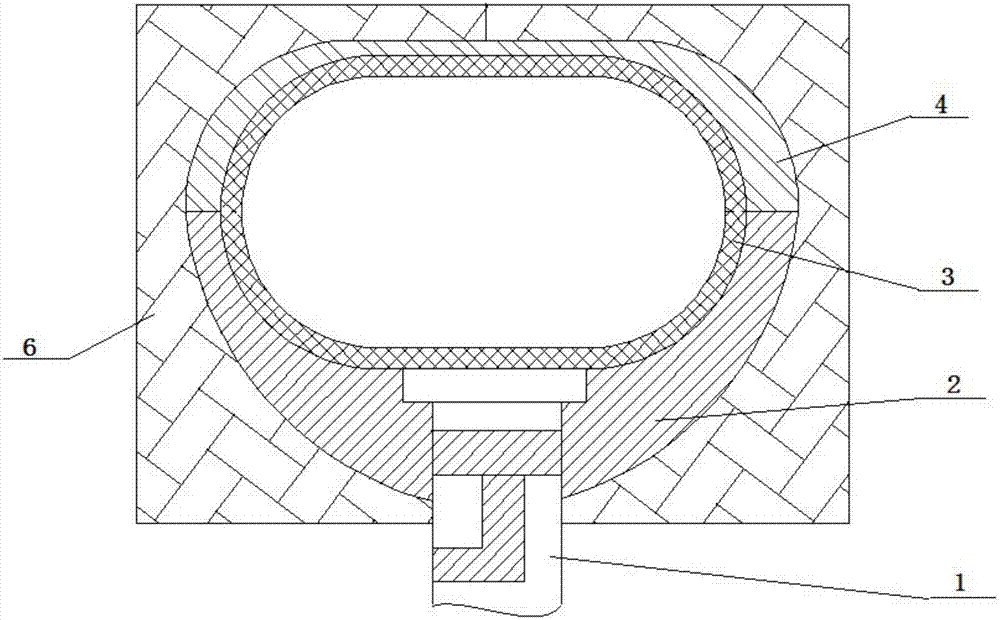

[0047] 1) Put the annular hollow tube 3 on the annular outer side of the mounting convex strip 13 on the rim 1;

[0048] 2) Put the mutually socketed rim 1 and the annular hollow tube 3 into the mold 6 together;

[0049] 3) Inject rubber material into the mold 6 through the injection hole 12, the rubber material flows into the mold 6 through the small hole 11 and forms the connecting layer 2 according to the shape of the mold 6;

[0050] 4) Open the mold 6, and solidify the semi-finished product after the glue injection;

[0051] 5) Paste tread glue on the outer surface of the annular hollow tube 3, and attach the tread 4 to the outside of the annular hollow tube 3 through the tread glue;

[0052] 6) Curing the tread 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com