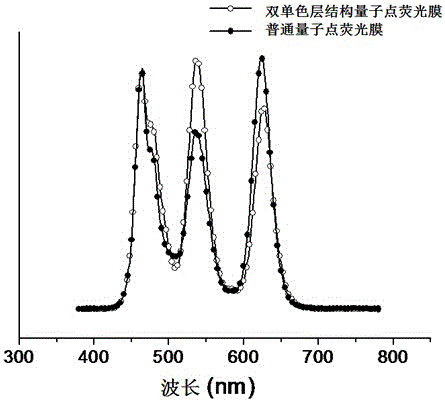

Quantum dot fluorescent film with double-monocolor-layer structure and manufacturing method thereof

A technology of red quantum dots and quantum dots is applied in the field of double-monochromatic layer structure quantum dot fluorescent film and manufacturing, which can solve the problems of high manufacturing cost of quantum dot fluorescent film and restrict the development of quantum dot technology, so as to reduce the amount of quantum dots, The effect of high optical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

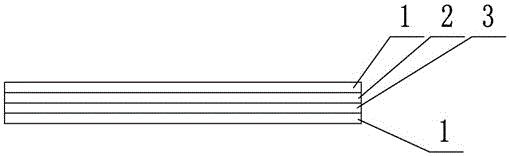

[0056] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

[0057] Embodiments of the present invention The embodiments of the present invention provide a double monochromatic layer structure quantum dot fluorescent film, including two layers of substrates 1 pressed together, the substrates are PET films, and the substrates on both sides The opposite inner surfaces are respectively provided with a green quantum dot inner film layer 2 made of green quantum dot composite colloid and a red quantum dot inner film layer 3 made of red quantum dot composite colloid.

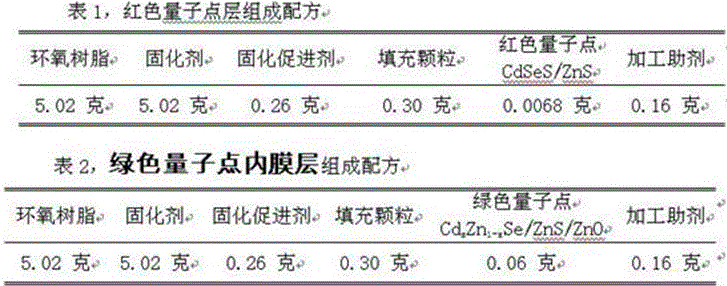

[0058] Wherein said green quantum dot composite colloid is made of the following materials by weight percentage:

[0059] Green quantum dot material 0.5-7 wt%

[0060] Epoxy resin 30-60 wt%

[0061] Curing agent 30-60 wt%

[0062] Curing accelerator 1-5 wt%

[0063] Filler particles 1-20 wt%

[0064] Processing aid 0-2 wt%

[0065] Wherein the red q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com