cutting device

A technology of cutting devices and cutting tools, which is applied in the direction of fine working devices, working accessories, manufacturing tools, etc., and can solve the problems of high cost and poor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, preferred embodiments of the cutting device according to the present invention will be described in further detail with reference to the drawings.

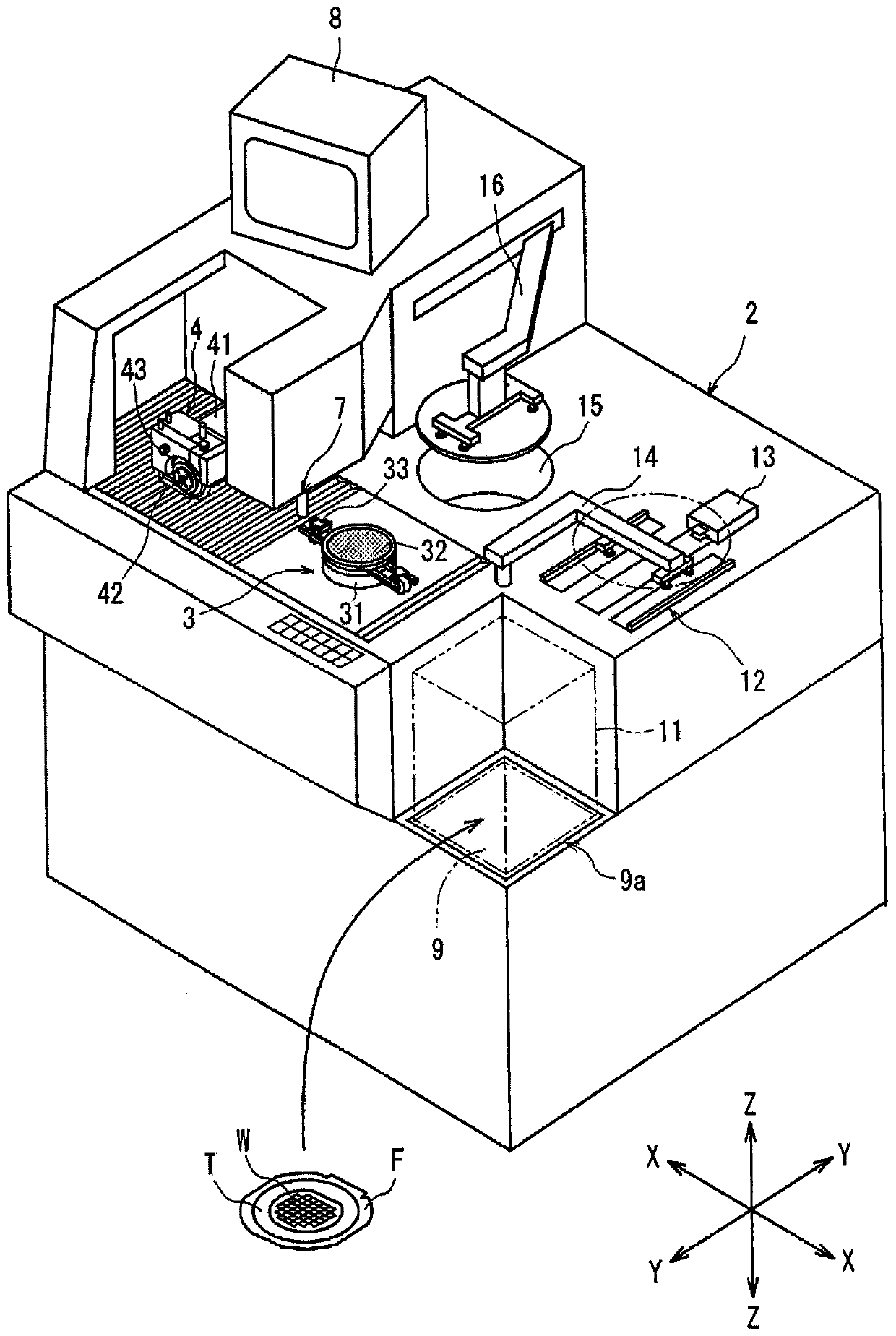

[0014] figure 1 A perspective view of a cutting device constructed in accordance with the present invention is shown in . figure 1 The cutting device shown has a substantially cuboid device housing 2 . In the device case 2, a chuck table 3 as a workpiece holding member for holding a workpiece is arranged so as to be movable in a direction indicated by an arrow X (X-axis direction) which is a cutting feed direction. The chuck table 3 has a suction chuck support table 31 and a suction chuck 32 arranged on the suction chuck support table 31, and the suction chuck 32 is placed on top of the suction chuck 32 by operating a suction member (not shown). The holding surface of the surface attracts and holds the workpiece. In addition, the chuck table 3 is configured to be rotatable by a not-shown rotation mechanism. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com