High-throughout preparing device and preparing method for metal solidification samples

A metal solidification and preparation device technology, which is applied in the control of molten metal pouring from ladles, metal processing equipment, casting equipment, etc., can solve the problem of huge material gene pool, achieve simple and effective control of experimental variables, and accelerate the establishment of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

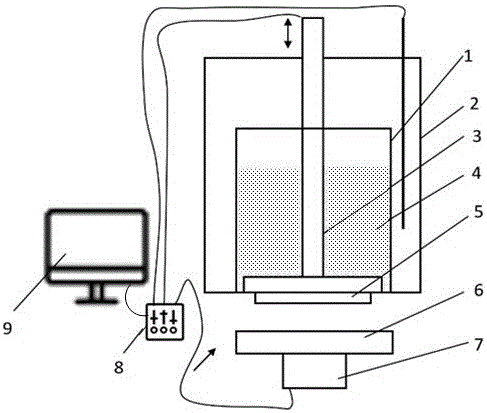

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

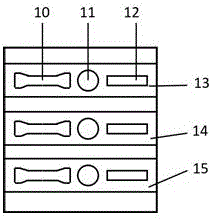

[0023] Such as figure 1 As shown, the high-throughput preparation device for metal solidification samples of the present invention includes a crucible 1, a resistance furnace 2, a stopper 3, a temperature measuring element 4, a slit-shaped nozzle 5, an array cooling platform 6, a mobile system 7, and a microcomputer control system , the crucible 1, the stopper rod 3 and the temperature measuring element 4 are all located in the resistance furnace 2, and the metal sample is smelted under temperature control; A thin layer of fluid flows out; the array cooling platform 6 is located directly below the slit-shaped nozzle 5, the array cooling platform 6 is connected to the mobile system 7 located at its bottom, and the microcomputer control system controls the resistance furnace 2, stopper rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com