An isothermal reactor

A technology of isothermal reactors and heat exchange tubes, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of increased equipment costs, untimely heat transfer, waste of materials, etc., to improve catalytic reaction efficiency, Effect of equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

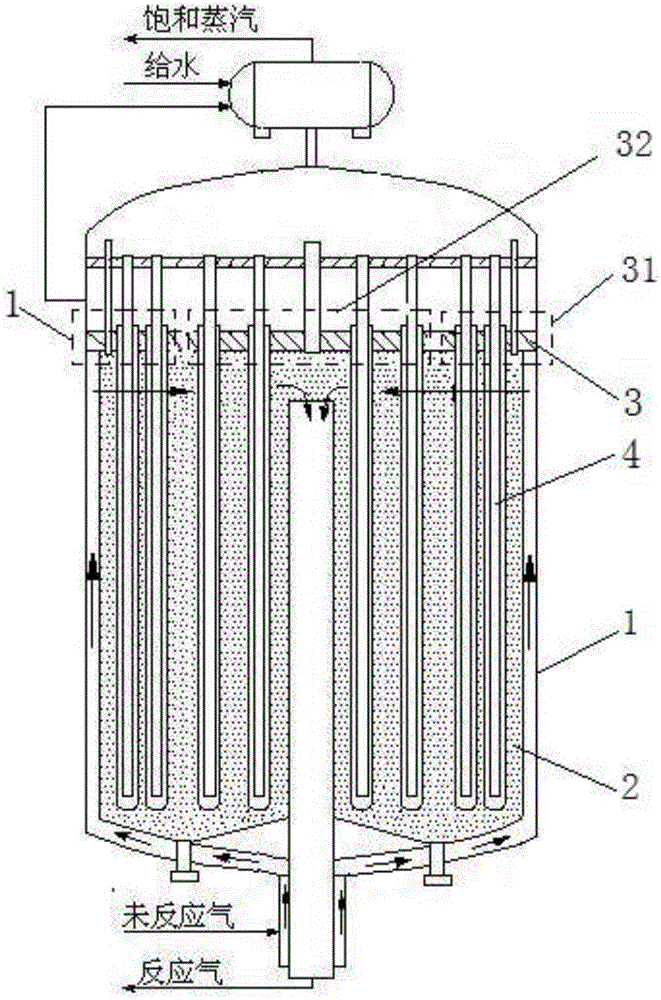

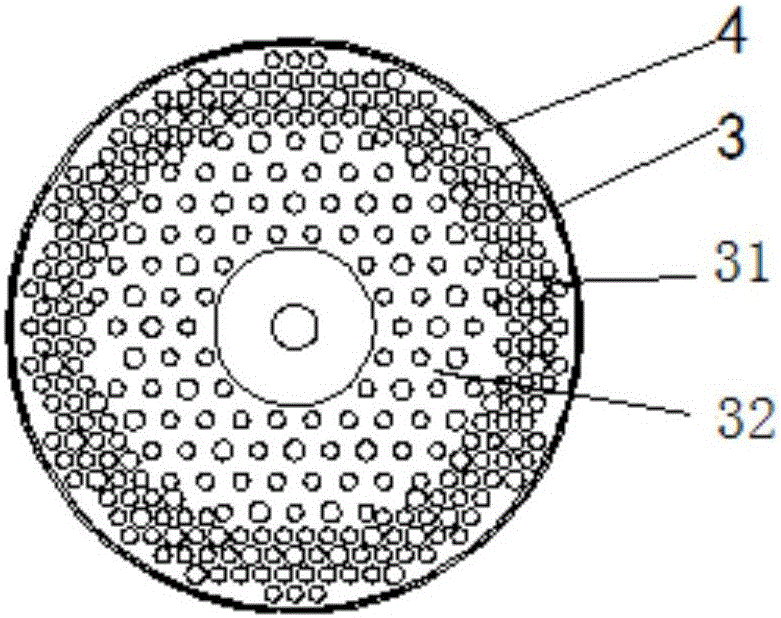

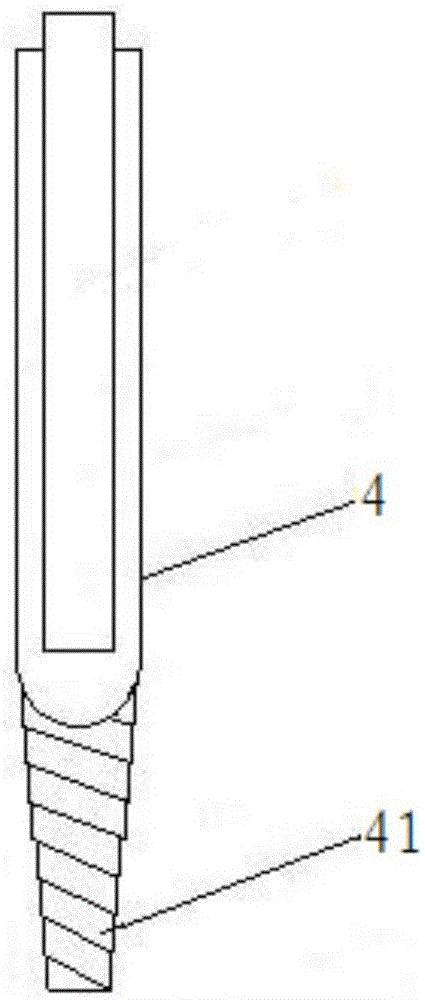

[0029] An isothermal reactor such as figure 1 As shown, it includes a shell 1, a catalyst bed 2, a tube sheet 3 and a heat exchange tube 4. The upper end of the heat exchange tube 4 is installed on the tube sheet 3, and the lower end of the heat exchange tube 4 extends into the catalyst. In the bed layer 2, the tube sheet 3 includes at least two installation areas where the heat exchange tubes 4 are arranged with different densities.

[0030] Such as figure 2 As shown, each installation area is an annular area with the center of the tube plate 3 as the center. figure 2 Among them, there are two installation areas, which are dense area and sparse area respectively, and the arrangement density of the heat exchange tubes 4 in the dense area is higher than that in the sparse area. Such as figure 1 As shown, the reaction gas flows from the inner wall of the isothermal reactor shell to the center of the catalyst bed, the dense area is the ring area 31 near the edge of the tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com