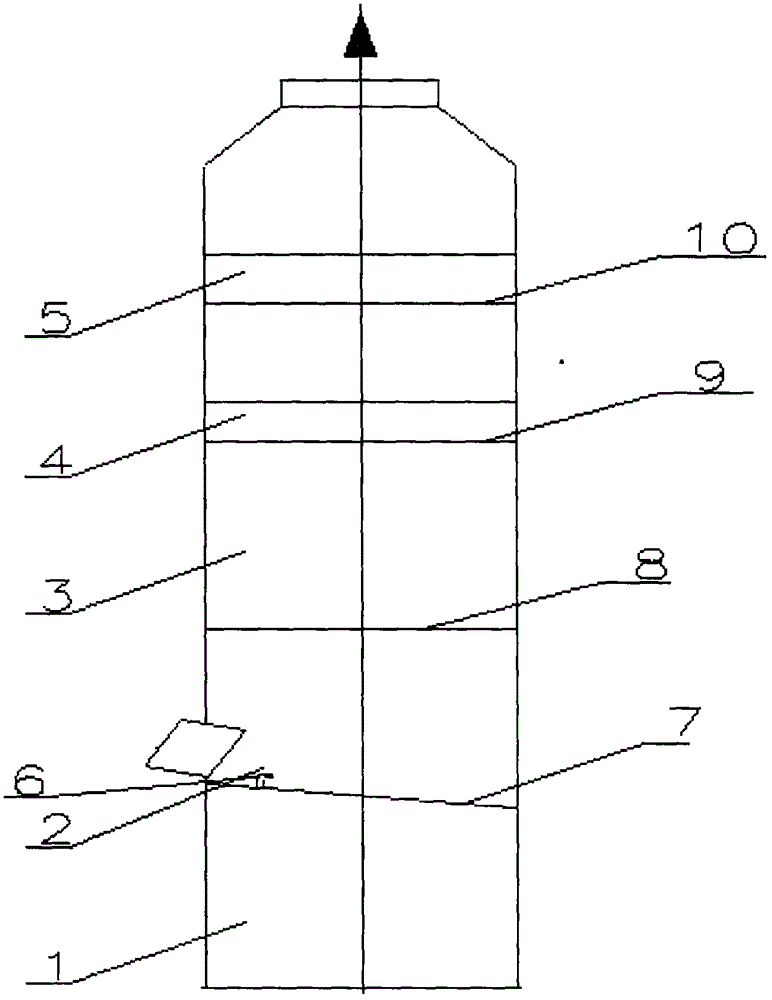

Single-tower five-section gradient purification, sulfur removal and dust removal ultra-low emission integrated device

A desulfurization and dust removal, cascade technology, applied in the direction of gas treatment, use of liquid separation agent, chemical instruments and methods, etc., can solve the problem that the desulfurization system design emission indicators of ordinary empty tower spraying cannot meet the national requirements, flue gas tailing products, Without solving the problems of ammonia desulfurization and other problems, it has achieved the effect of high desulfurization and dust removal efficiency, simple and clear structure, and is conducive to wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] Specific implementation: the content of total particulate matter (aerosol and dust evenly represented in the form of particulate matter) in flue gas after desulfurization is not more than 5mg / Nm3, and its measurement adopts GB / T16157-1996 "Determination of particulate matter in exhaust gas from fixed pollution sources and gaseous pollutants" Sampling method" standard; the total particle content in the flue gas after desulfurization of the existing desulfurization system is 30mg / Nm3, which is reduced by 83.3%, and the SO2 content in the flue gas after desulfurization is not more than 35mg / Nm3, which meets DB371-2373-2013 "Comprehensive Discharge Standards of Regional Air Pollutants in Shandong Province".

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com