Large-capacity commercial purification sink

A large-capacity, sink technology, applied in the field of kitchen appliances, can solve the problems of occupying space in the kitchen or other places, losing expansion performance, occupying space, etc., to achieve faster washing speed and washing volume, simple and reliable water circulation system, and removal of pesticide residues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

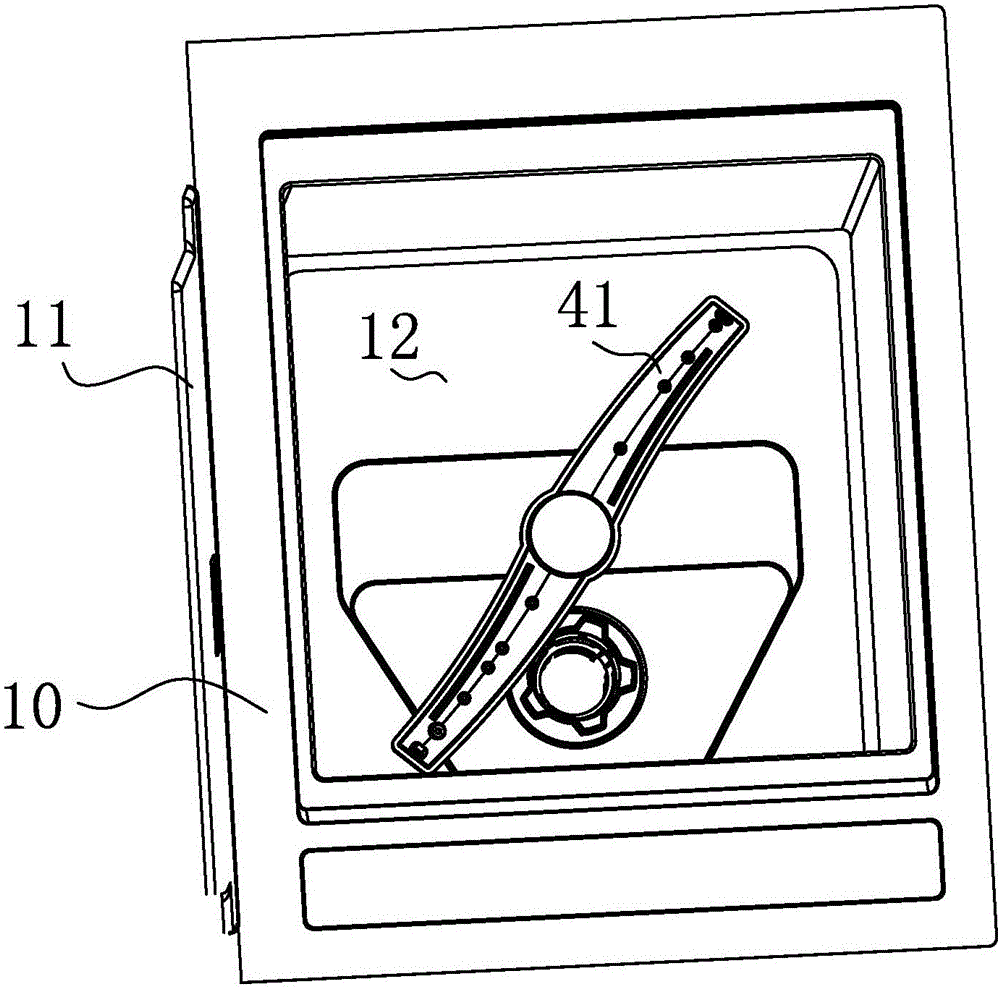

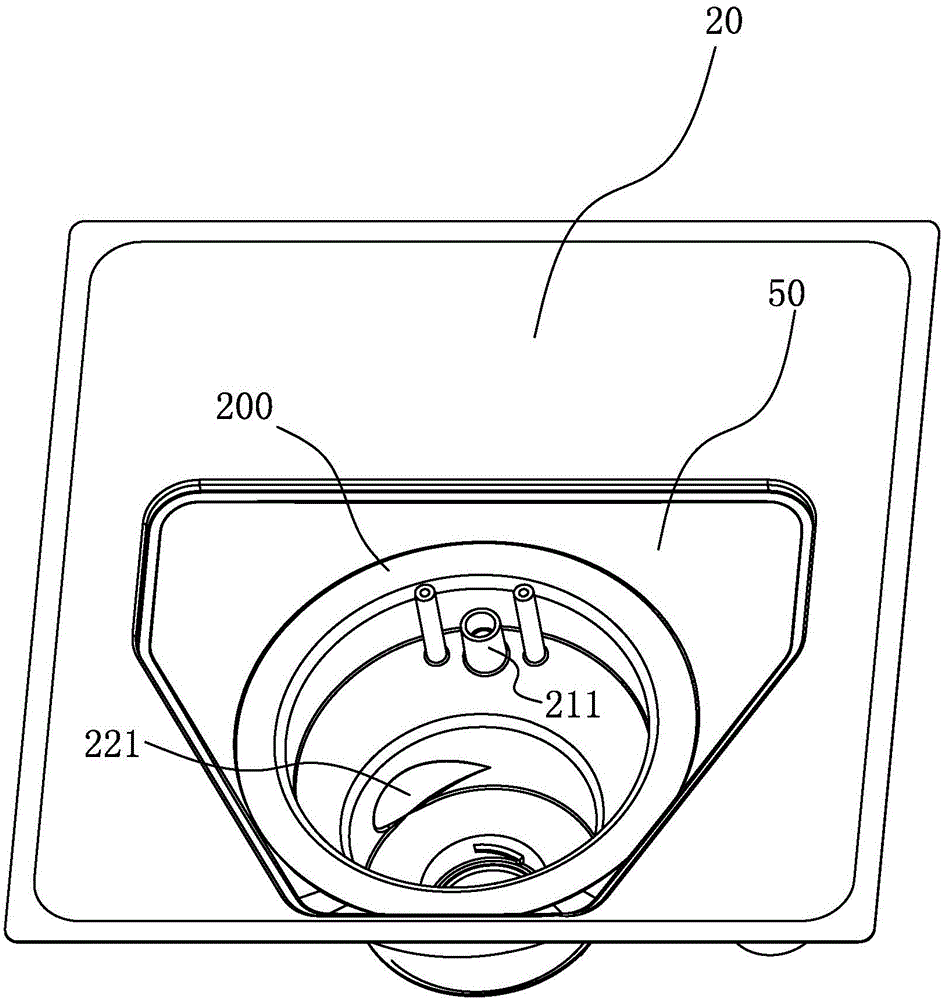

[0050] Please refer to Figure 1-Figure 4 as well as Figure 14 , the large-capacity commercial purified water tank of the present invention includes a tank body 10, and the tank body 10 has a table 13. The tank body 10 also includes a side wall 11 and a bottom wall 12. An opening is formed at the top of the tank body 10 and a countertop 13 is arranged around the opening. The side wall 11 and the bottom wall 12 enclose a washing space of a sink type cleaning device.

[0051] The plasma generator has an electrode head 110 and a control part 120 electrically connected to each other, the control part 120 is embedded on the table 13, and the electrode head 110 is embedded on the side wall 11 of the tank body 10;

[0052] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com