A fully automatic production line for fruit core shaping and expelling gas in the core

A production line, fully automatic technology, applied in the fields of application, food forming, food science, etc., can solve the problems of hydraulic press consumption, backward technology, easy pollution, etc., achieve the stability of the pressure-holding tank, avoid repeated investment, and ensure continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

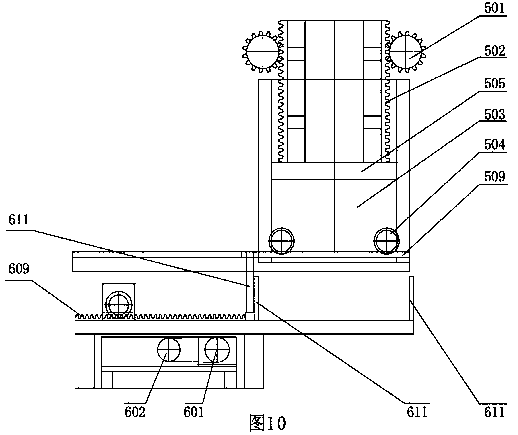

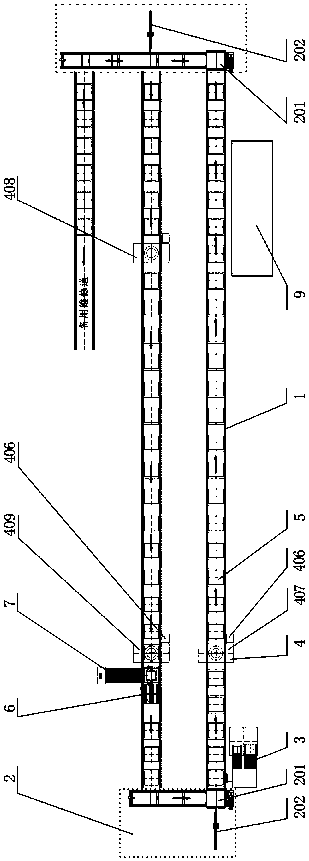

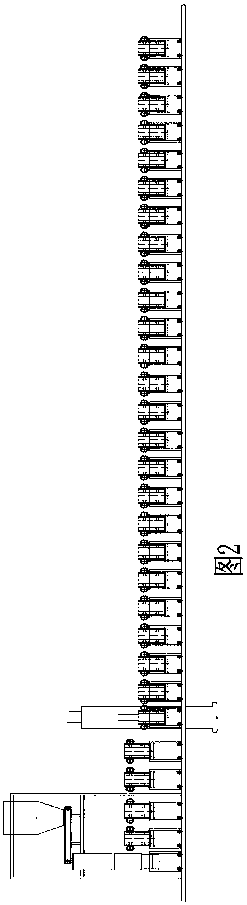

[0036] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] see Figure 1-10 , a fully automatic production line for fruit stone (mango stone) shaping and discharging the gas in the nucleus, including three walking guide rails for pressure-holding tank cars laid parallel to each other on the ground plane, 1, the inlet end direction changing devices respectively arranged at both ends of the guide rails and The direction changing device 2 and the hydraulic propulsion device 202 at the outlet end, the automatic feeding, weighing, metering and distributing system 3 arranged on one side of the guide rail, the pressure-holding tank car 5, the first station servo hydraulic machine 407 arranged on one of the guide rails, and the The second station servo hydraulic press 408 of the other guide rail, the third station servo hydraulic press 409, the third station servo hydraulic press has a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com