Core-injected Chinese evergreenchinkapin seed cake production device and method thereof

A production device, core-injecting cone chestnut technology, applied in the field of core-injection cone chestnut cake production equipment, can solve the problems of out-of-synchronization of freshness of cake blanks and affect the taste, achieve stable working mode, improve the taste of finished products, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the cake filling comprises the following steps in sequence.

[0039] A1. Soak peas, mung beans, and shelled chestnut meat in water for 4 hours.

[0040] A2. Put the soaked peas, mung beans, and shelled chestnut meat into the rice steamer, and steam for 1 hour under the steam working pressure of 0.03MPa.

[0041] A3. Put the steamed peas, mung beans, shelled chestnut meat, sugar, soybean oil, maltose, seasoning liquid containing salt and food flavor into a blender and stir evenly to form a dough.

[0042] A4. Put the ingredients into a cooking pot and cook for 40 minutes after stirring evenly to form a ball. .

[0043] In the preparation process of the cake filling, the component distribution ratio of peas, mung beans, shelled chestnut meat, sugar, soybean oil, maltose, salt and edible flavoring liquid is: Peas 25%, mung beans 12.5%, shelled Chestnut meat 12.5%, sugar 20%, soybean oil 18%; maltose 7%; seasoning liquid containing salt and food...

Embodiment

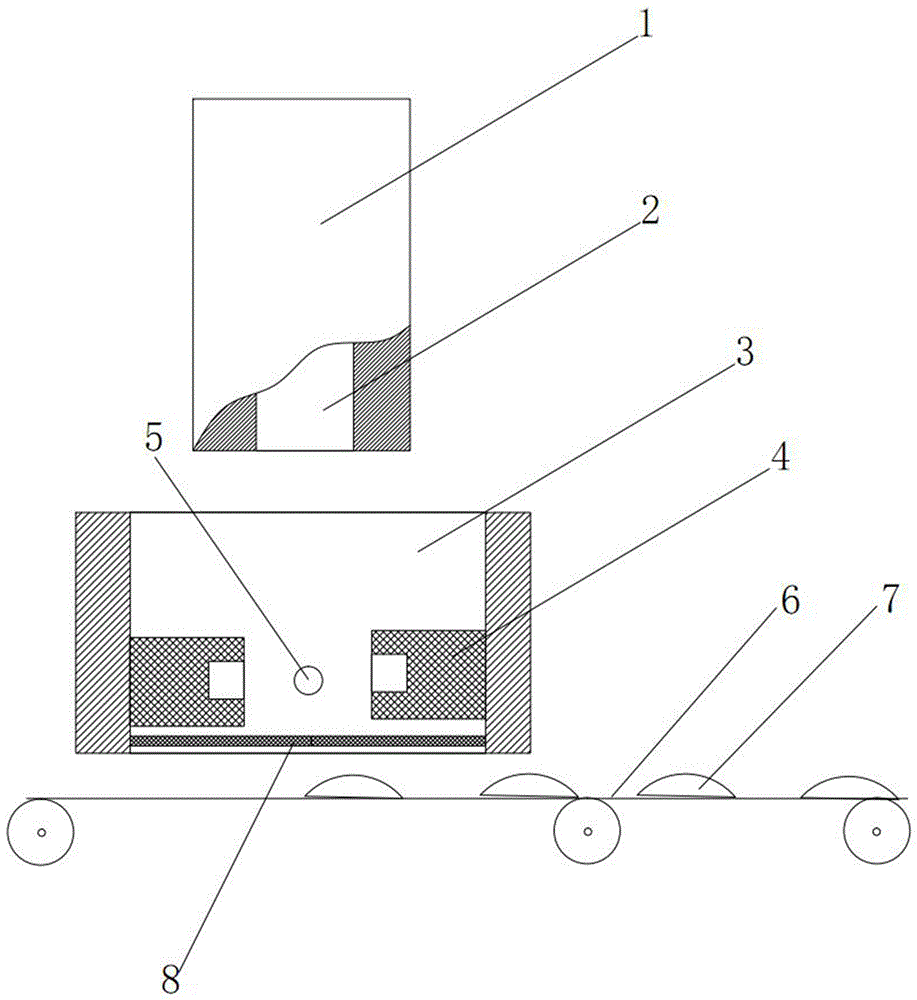

[0049] The operator first prepares dough materials and fillings, fills the prepared dough into the leather extrusion part 1, then fills the prepared fillings into the filling extrusion part, and starts the production device.

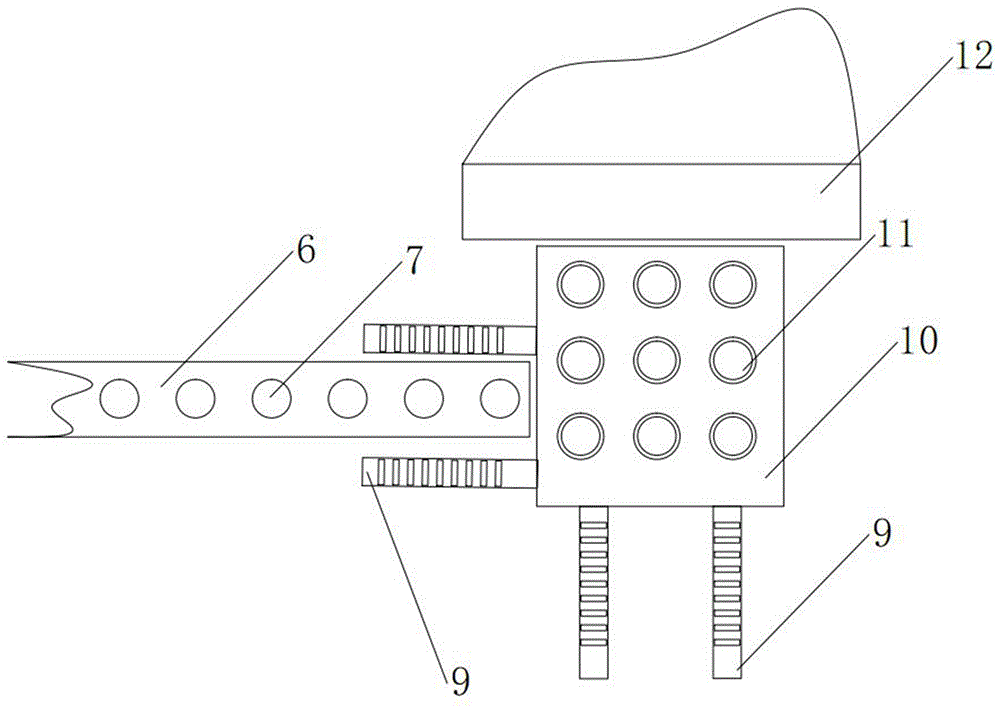

[0050] The forming standpipe 3 moves upwards, close to the leather outlet of the leather extrusion part 1, the baffle plate 8 at the bottom of the forming standpipe 3 closes the outlet at the bottom of the standpipe 3, and the leather extrusion part 1 is formed through the leather outlet 2 The bottom baffle 8 of the standpipe 1 injects the dough, then the forming standpipe moves down, the stuffing extruding part injects the cake filling on the dough at the baffle 8 through the stuffing outlet 5, the mold shells of the forming mold 4 are put together, and the mold The shell squeezes the dough and cake filling during the joining process, so that the dough is covered with the cake filling to form a cored dough 7. After the cored dough 7 is formed, the mold s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com