Lithium ion battery electrolyte and lithium ion battery using same

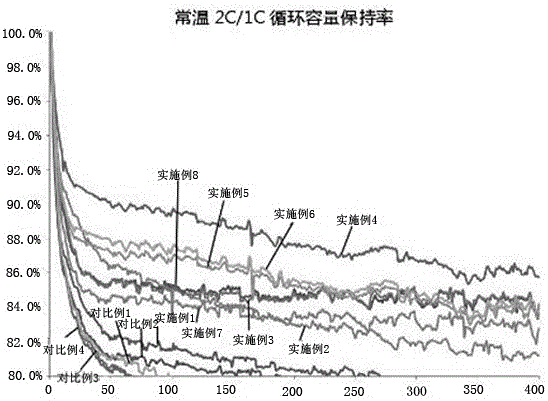

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of high-temperature storage and poor cycle performance, and achieve the effects of excellent cycle performance, excellent capacity, and excellent fast charging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Electrolyte preparation:

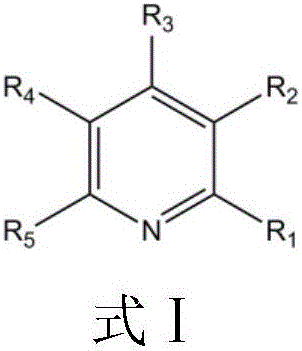

[0034]In a glove box filled with argon (moisture content 6 , then add 3% fluoroethylene carbonate in mass fraction, 1% adiponitrile in mass fraction and 0.5% 2,6-dipyridinedicarboxamide in mass fraction, and stir until completely dissolved to obtain Example 1 Lithium-ion battery electrolyte.

[0035] Preparation of lithium-ion batteries:

[0036] After the positive electrode active material lithium cobaltate, the conductive agent Super P, and the binder polyvinylidene fluoride (PVDF) are fully stirred and mixed in the N-methylpyrrolidone solvent system at a mass ratio of 95:3:2, they are coated on Dry and cold press on Al foil to obtain the positive electrode sheet, the compacted density is 4.0g / cm 3 .

[0037] Negative electrode active material graphite, conductive agent Super P, binder styrene-butadiene rubber (SBR), thickener carbon methyl cellulose sodium (CMC) were mixed in a deionized water solvent system according to the mass ratio o...

Embodiment 2

[0041] Different from Example 1 is the preparation of electrolyte:

[0042] In a glove box filled with argon (moisture content 6 , then add 3% fluoroethylene carbonate, 1% adiponitrile and 3% 2,6-dipyridinedicarboxamide by mass fraction, and stir until completely dissolved to obtain Example 2 lithium-ion battery electrolyte.

[0043] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0045] Different from Example 1 is the preparation of electrolyte:

[0046] In a glove box filled with argon (moisture content 6 , then add mass fraction of 3% fluoroethylene carbonate, mass fraction of 1% adiponitrile and mass fraction of 0.5% 2-pyridine carboxamide, stir until completely dissolved, namely obtain the lithium ion of Example 3 battery electrolyte.

[0047] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com