Fiber grating acceleration sensor with integrated differential structure

An acceleration sensor and fiber grating technology, applied in the sensor field, can solve the problems of reliability, thermal stability frequency response and insufficient sensitivity, and achieve the effect of eliminating thermal influence, simple installation process, and reducing process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

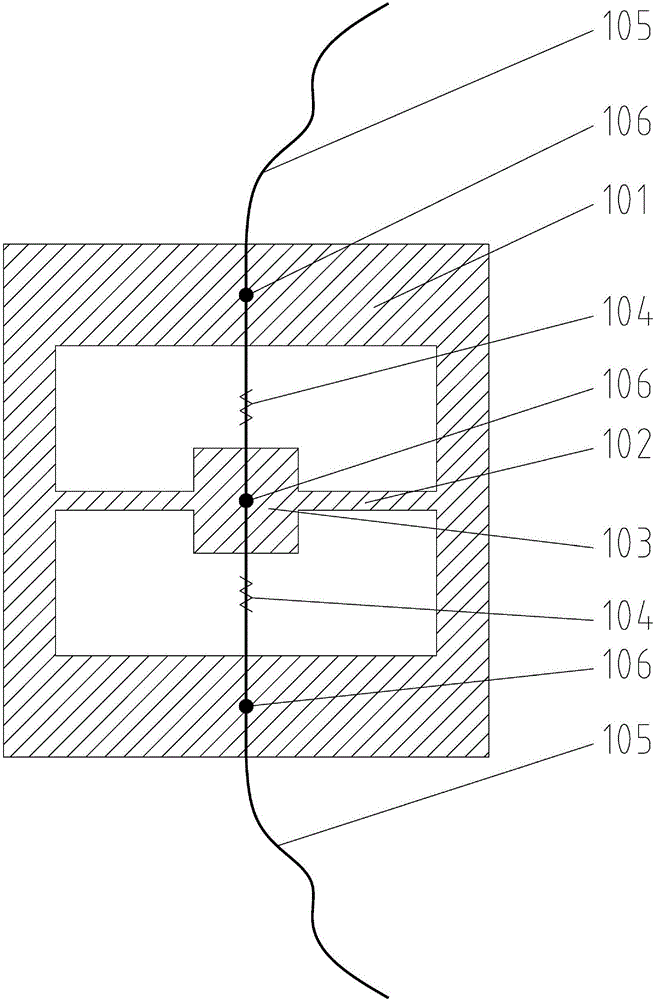

[0020] Such as figure 1 Shown is a fiber grating acceleration sensor with an integrated differential structure. It can be seen from the figure that it includes a support structure (101), an elastic beam (102), a mass (103) and a fiber grating ( 104) the optical fiber (105);

[0021] Connection method: After tensioning the optical fiber (105) with two fiber gratings (104), it is fixedly connected with the two ends of the support structure (101) and the middle point of the mass block (103) with glue points or solder points (106), And make the optical fiber (105) in the central axis position of the support structure (101);

[0022] Acceleration measurement principle: the external acceleration causes the mass block (103) to generate inertial force, and under the joint action of the mass block (103) inertial force and the elastic beam (102) restoring force, the tension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com