A fuel preheating system for diesel vehicles

An oil supply system and diesel technology, which is applied in the charging system, fuel heat treatment device, liquid fuel feeder, etc., can solve the problems of cost consumption, tight supply of high-grade diesel in winter, and thickening of diesel, and reduce wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

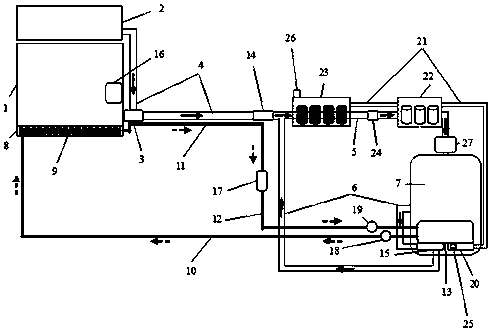

[0019] In this embodiment, the oil supply system includes a main oil tank 1, an auxiliary oil tank 2, a two-position three-way solenoid valve 3, an oil outlet pipe 4, an oil inlet pipe 5, and an oil return pipe 6. The two-position three-way solenoid valve 3 is respectively connected to the main oil tank 1, Auxiliary fuel tank 2, oil outlet pipe 4, oil outlet pipe 4 is connected to oil inlet pipe 5, oil inlet pipe 5, oil return pipe 6 form a circuit through automobile engine 7, and oil inlet pipe 5 is connected to automobile engine 7 to be provided with high-pressure oil pump 27, water circulation preheating system includes main Fuel tank heating, 8, heat exchanger 9, water outlet pipe 10, heating water pipe 11, return water pipe 12, heat exchanger 9, water outlet pipe 10, heating water pipe 11, return water pipe 12 and automobile engine water tank 13 form a circuit, heat exchanger 9 Installed in the heating chamber 8 of the main oil tank, the heating chamber 8 of the main oil t...

specific Embodiment approach 2

[0028] The main improvement of this embodiment lies in the addition of a warm air preheating system. The warm air preheating system includes a heater 20, a warm air pipe 21, a diesel filter heating chamber 22, an oil-water separator heating chamber 23, and a diesel filter heating chamber. The chamber 22 is connected with the heating chamber 23 of the oil-water separator, the heater 20 and the diesel filter heating chamber 22 through the warm air pipe 21, and the heater 20 is installed at the front end of the radiator of the automobile engine.

[0029] Preferably, the warm air preheating system also includes an oil inlet pipe temperature sensor 24 and a temperature control switch 25 connected to each other. The oil inlet pipe temperature sensor 24 is installed on the oil inlet pipe 5 at a position between the oil-water separator and the diesel filter. The line controls the temperature control switch 25 on the heater 20 to adjust the speed of the heater 20, and the temperature co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com