Large-tonnage carbon fiber superimposed plate bundle anchorage

A technology of carbon fiber and laminated plates, applied in structural elements, building components, buildings, etc., can solve the problems of carbon fiber plate bundles being damaged, unable to adjust, damage, etc., to achieve strong resistance to radial compression deformation, improve anchoring efficiency, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

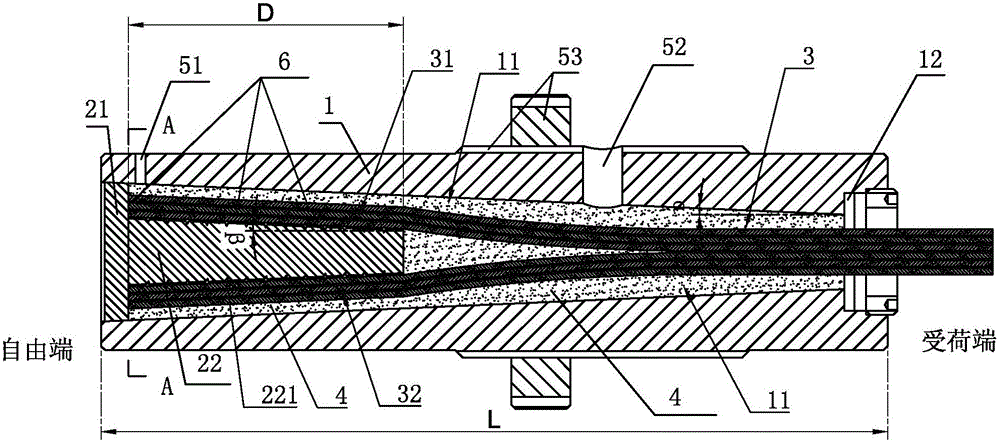

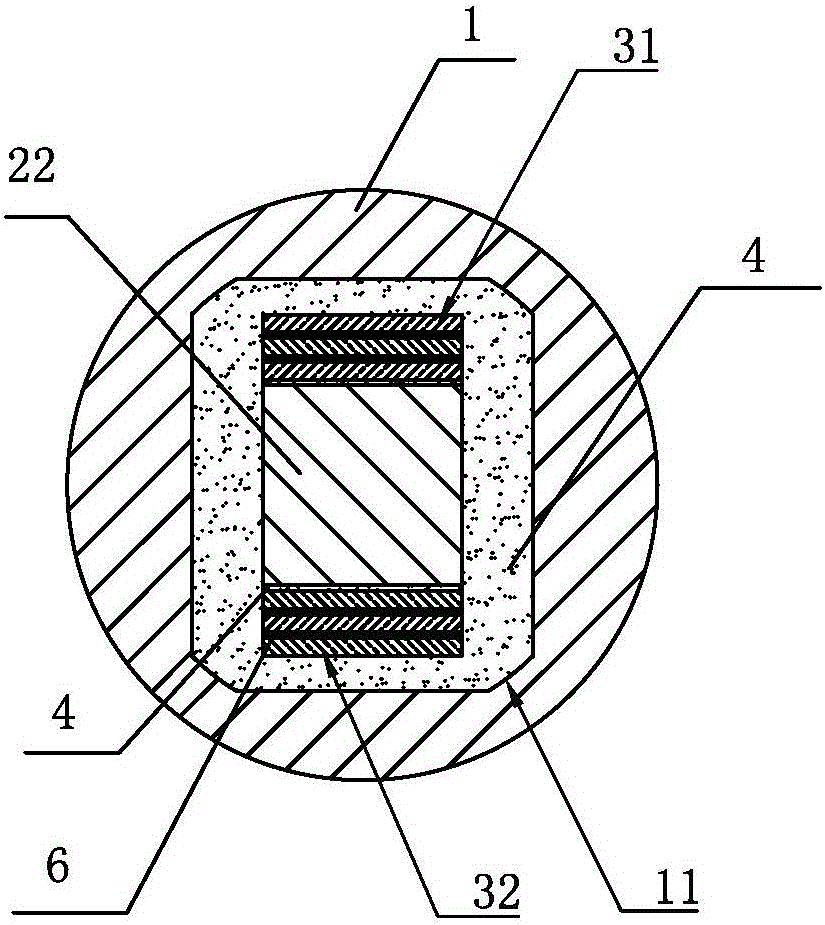

[0017] Embodiment 1: A large-tonnage carbon fiber laminated plate beam anchorage, including an anchor barrel 1 and a carbon fiber fixed plate bundle arranged in the anchor barrel, the anchor barrel 1 is provided with a filling through hole 11, and the cross section of the filling through hole 11 is a square A chamfered square hole is provided, a sealing cover plate 21 is provided at the end of the filling through hole 11, a terminal seal 12 is provided at the front end of the filling through hole 11, and the carbon fiber fixed plate bundle 3 passes through the terminal seal 12 and enters the filling In the through hole 11, a wedge-shaped block 22 is arranged on the sealing cover plate 21, and the wedge-shaped block 22 extends inwardly to fill the through hole 11, and separates the carbon fiber fixed plate bundle 3 into a symmetrical first plate bundle 31 and a second plate bundle 32. The two sides of the wedge-shaped block 22 are symmetrically provided with two wedge-shaped slo...

Embodiment 2

[0018] Embodiment 2: The remaining parts are the same as Embodiment 1, the difference is that the epoxy resin mixed medium 4 is composed of epoxy resin and epoxy alumina, the inclination angle β of the inclined surface of the block is 1.5°, and the inclination angle of the inclined surface of the hole wall is 1.5°. α is 1.65°, and the length D of the wedge-shaped block 22 is 0.5 times the length L of the anchor cylinder 1 .

Embodiment 3

[0019] Embodiment three: the rest is the same as embodiment one, the difference is that the epoxy resin mixed medium 4 is composed of epoxy mortar, epoxy aluminum, epoxy iron sand and epoxy rock powder, and the inclination angle β of the slope of the block is is 3.5°, the inclination angle α of the slope of the hole wall is 3.5°, and the length D of the wedge-shaped block 22 is 0.7 times the length L of the anchor cylinder 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com