High-strength steel bar anchoring device and implementation method thereof

A technology of high-strength steel bars and anchoring devices, which is applied to building reinforcements, structural elements, building components, etc., can solve the problems of unstable anchoring structure, affecting anchoring efficiency, and poor thread quality, so as to avoid low anchoring efficiency and improve anchoring efficiency. , Enhance the effect of anchoring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

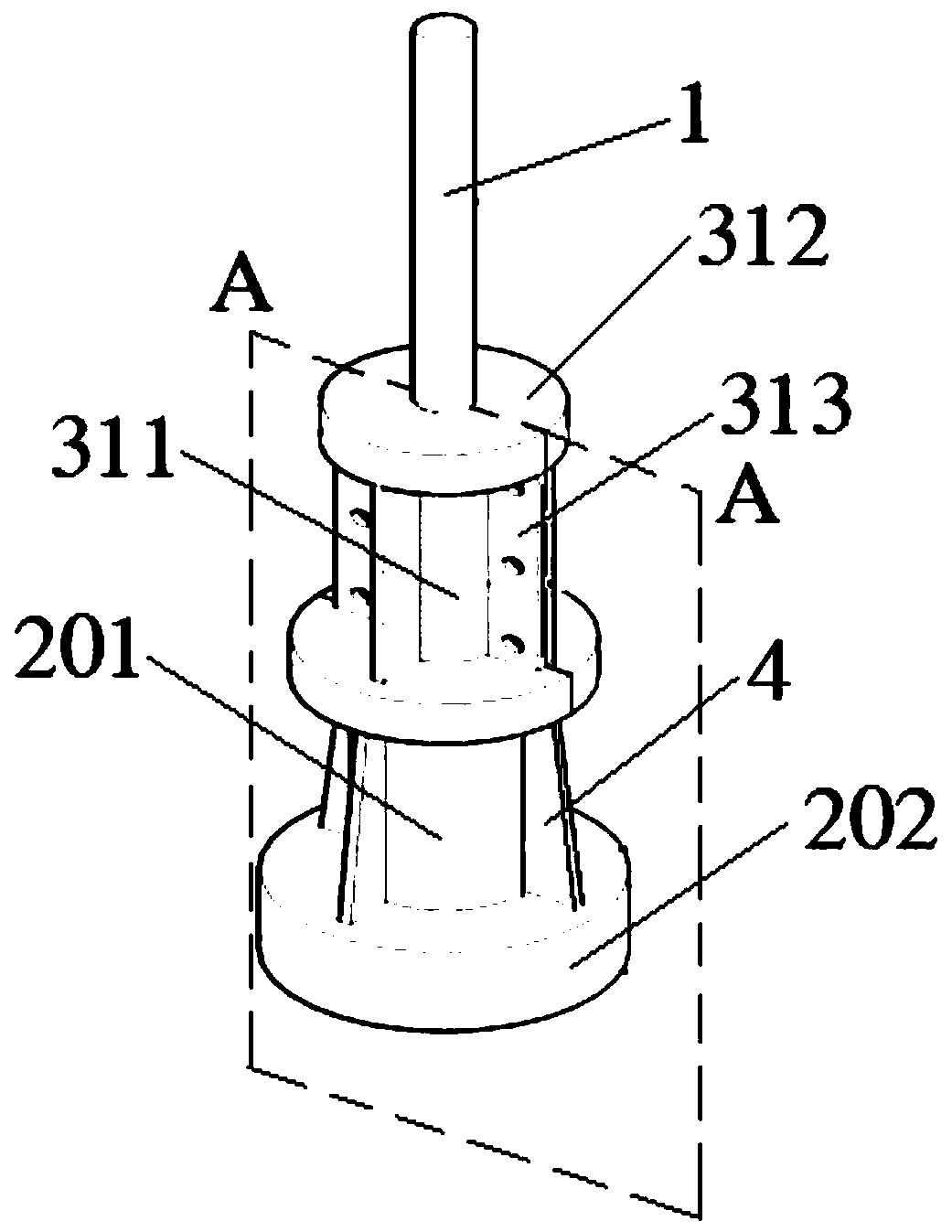

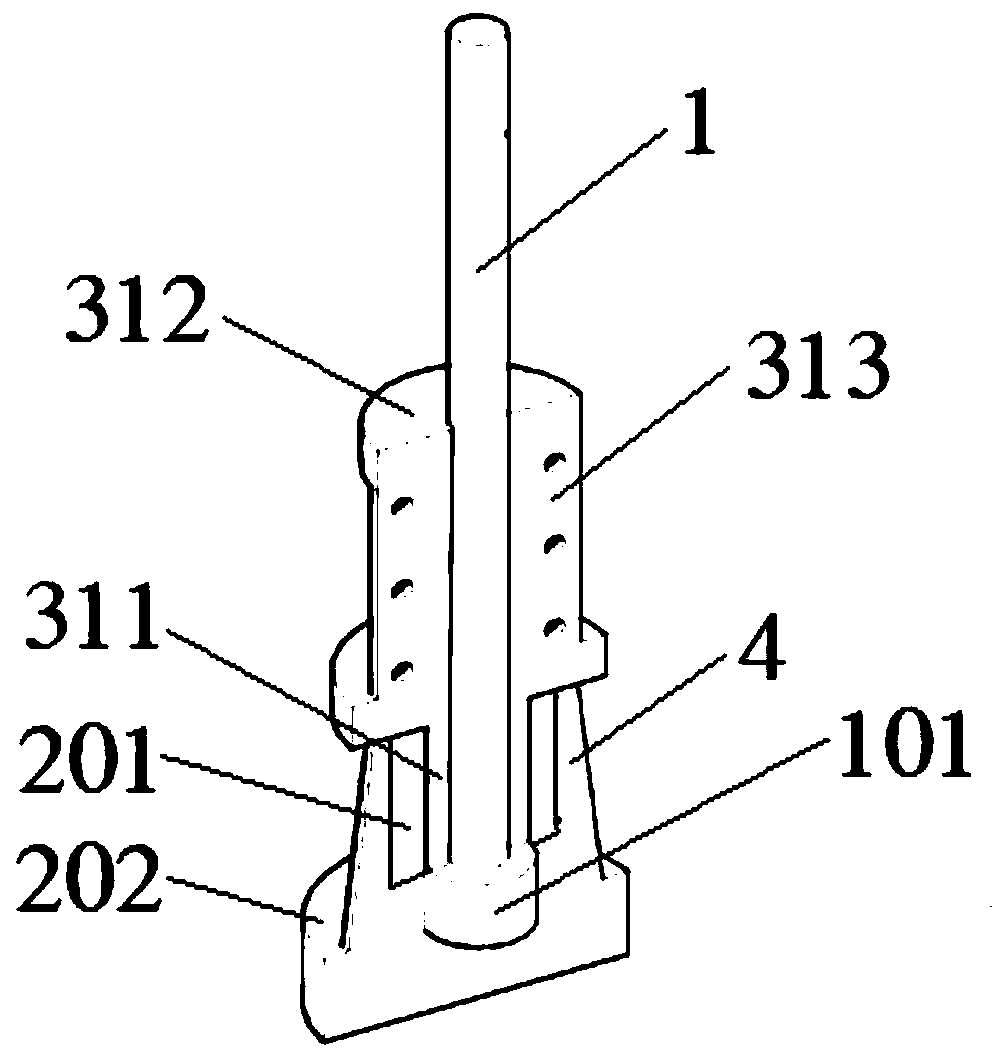

[0037] refer to Figure 1-Figure 7 An anchoring device for a high-strength steel bar 1 provided in an embodiment of the present invention includes a first anchor 2, a second anchor 3, and a high-strength steel bar 1 arranged sequentially from outside to inside; wherein, the end of the anchoring end of the high-strength steel bar 1 is thicker A pier head 101 is formed, the end of the pier head 101 of the high-strength steel bar 1 is covered with a first anchor 2, and the upper end of the first anchor 2 is higher than the upper surface of the pier head 101; the high-strength steel bar 1 on the upper side of the pier head 101 is covered with The second anchor 3 , the lower end of the second anchor 3 is close to the upper surface of the pier head 101 ; the upper end of the first anchor 2 is detachably fixedly connected to the lower end of the second anchor 3 .

[0038] In the above embodiments, the first anchor 2, the second anchor 3 and the high-strength steel bar 1 are sequentia...

Embodiment 2

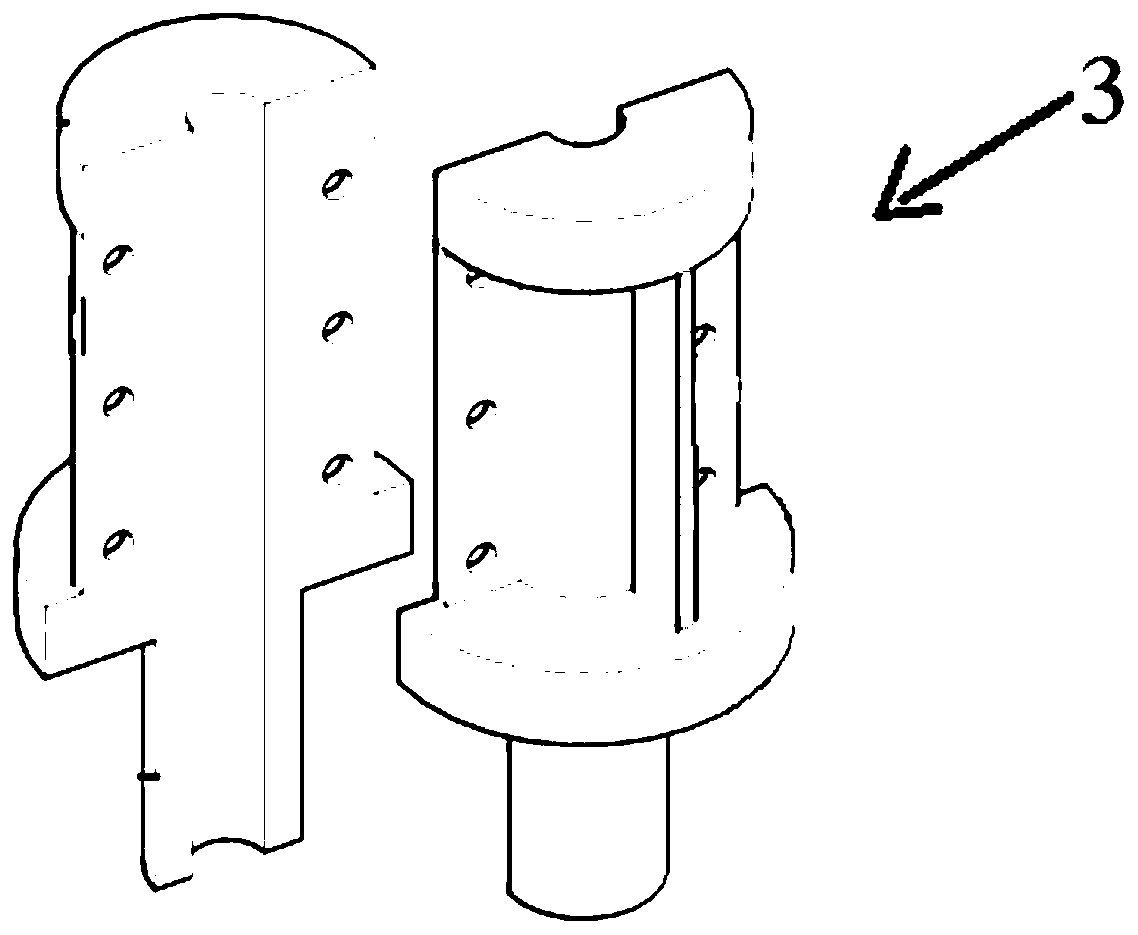

[0059] A kind of implementation method of high-strength steel bar anchorage device, refer to image 3 , including the following steps:

[0060] Step 1, hooping the first steel sleeve outside the pier head, so that the lower end of the first steel sleeve is flush with the lower surface of the pier head;

[0061] Step 2, hoop the second steel sleeve outside the high-strength steel bar, so that the lower end of the second steel sleeve is close to the upper surface of the pier head; The external thread of the first anchor is fixedly connected with the second anchor.

[0062] In Example 2 of the present invention, before installation, the high-strength steel pier head is prepared in advance in the factory, the first steel sleeve and the anchor base plate are integrally formed, and the second steel sleeve is integrally formed with multiple anchor plates on it to form the second anchor. The second anchor piece is divided into left anchor piece and right anchor piece from the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com