Ecological restoration method for metal mine waste yard

A technology for mine waste and ecological restoration, applied in botany equipment and methods, excavation, plant cultivation, etc., can solve problems such as ecological deterioration, environmental pollution of metal mine waste yards, etc., achieve mechanical properties and reduce engineering The effect of low cost and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

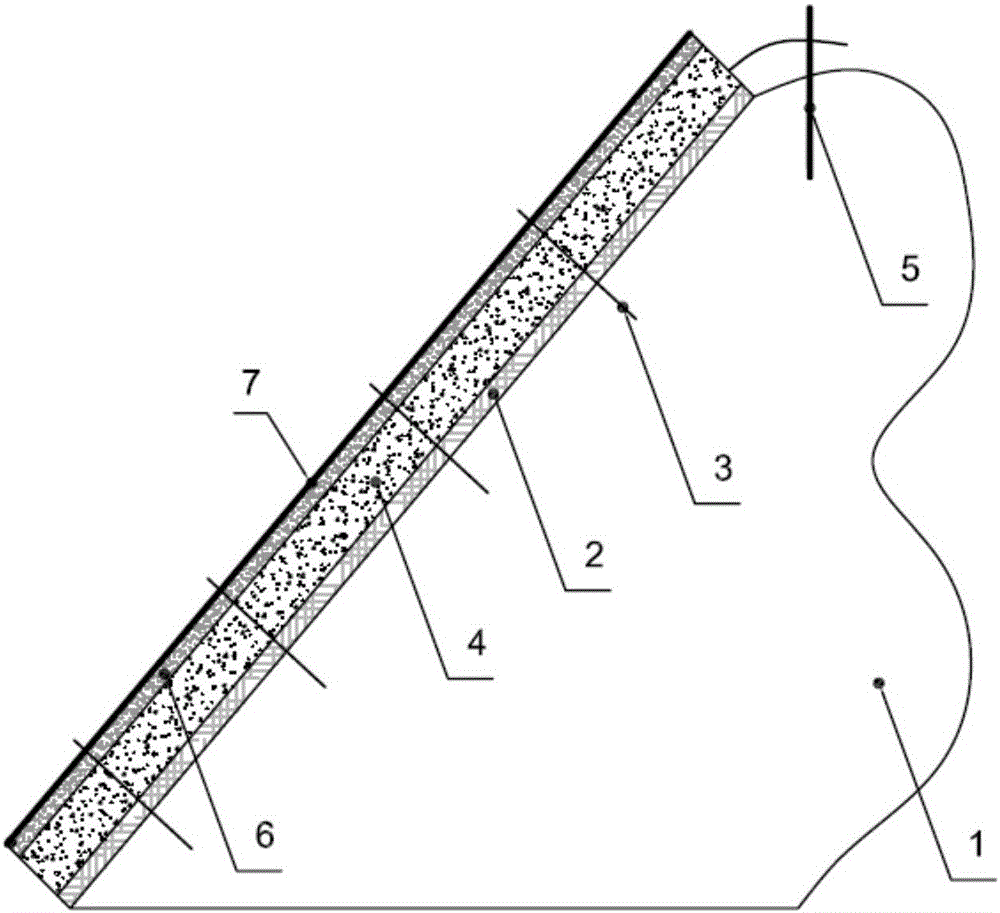

[0031] In this embodiment, the slope length of the storage yard 1 is 55 meters, without classification, and the slopes are all above 45°, and the slope of the storage yard 1 is relatively loose, and there is no soil layer, which seriously restricts the normal growth of plants. .

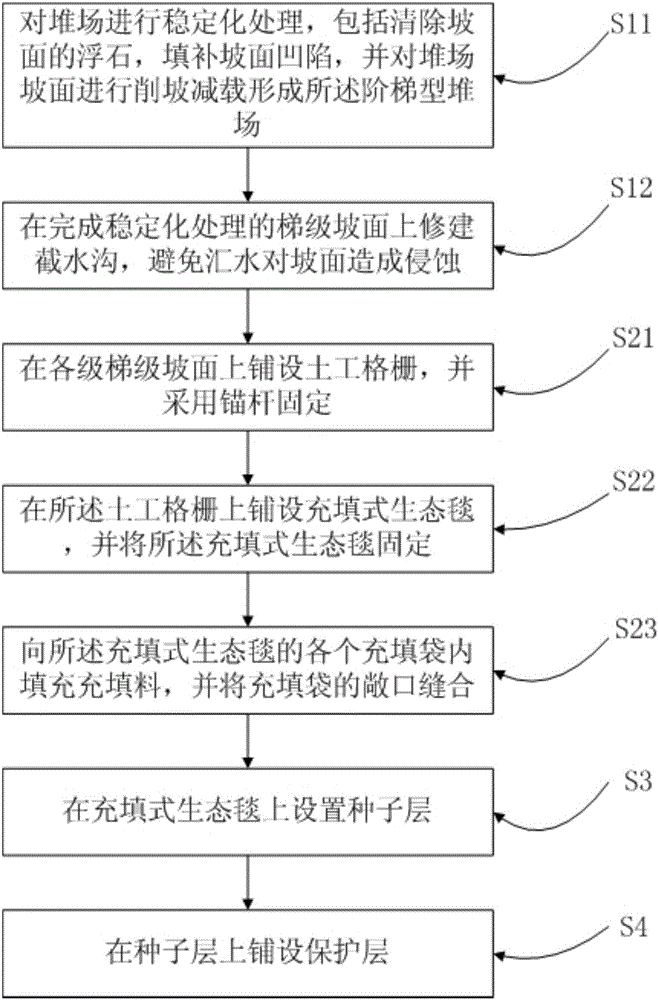

[0032] Such as figure 1 and image 3 As shown, the embodiment of the present invention provides an ecological restoration method for a metal mine waste dump, which mainly includes the following steps during implementation:

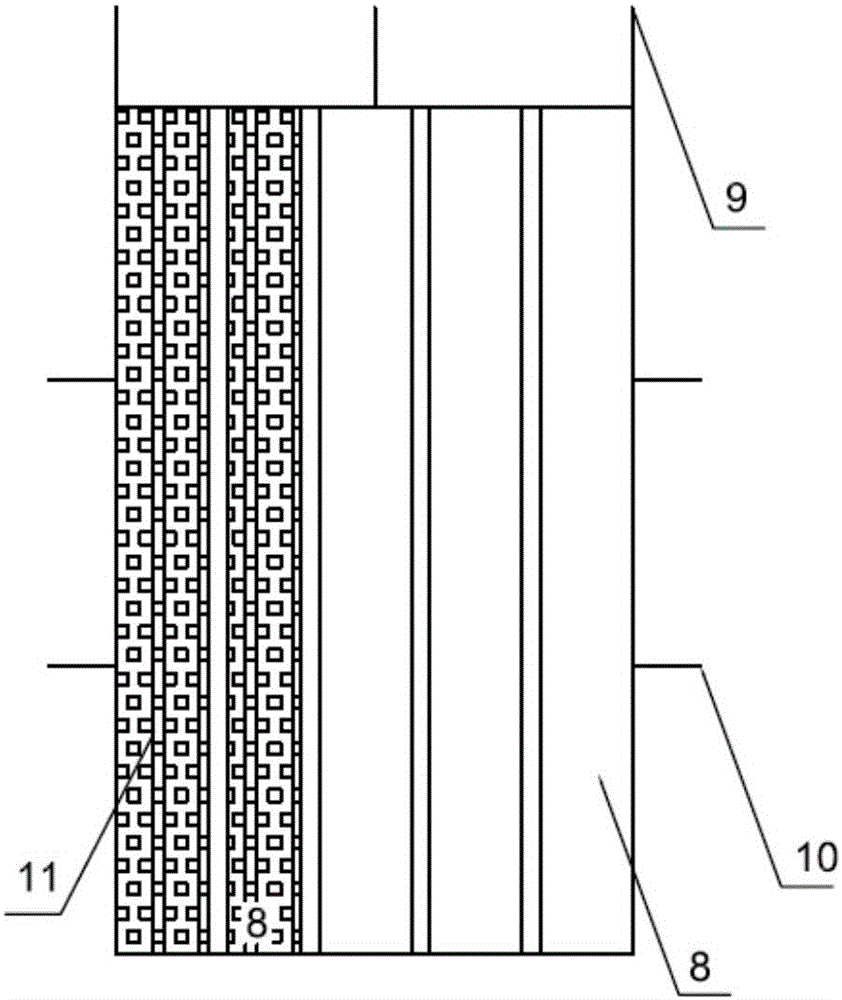

[0033] Step S1, repairing the metal mine waste storage yard 1 to form several ladder-shaped storage yards with trapezoidal slopes and slope cutting platforms; specifically, step S1 also includes step S11, performing stabilization treatment on the storage yard 1 , including clearing the pumice on the slope of the storage yard 1, filling the slope depression of the storage yard 1, and cutting the slope of the storage yard 1 to reduce the load to form a stepped storage yard. The l...

Embodiment 2

[0043] The slope length of the storage yard 1 in the embodiment of the present invention is 36m, is divided into two grades of side slopes, and the slope is all more than 55 °, and the slope of the storage yard 1 has a high degree of hardening, is alkaline, and does not have a soil layer. Not conducive to the restoration works of the preparation. When repairing the storage yard 1 of this embodiment, the construction steps are similar to those of the embodiment, and the similarities will not be repeated. The difference is that in step S23, the volume fraction A of the fermented sludge in the filling material 11 is 35%. , the volume fraction B20% of the light matrix, the volume fraction C of the loam is 45%, and the addition of the water-retaining agent is 500g; in step S3, the spraying thickness of the seed layer 6 is 4cm, and the volume of the light matrix in the seed layer 6 The fraction D is 40%, the volume fraction E of the loam is 60%, and the binder content is 12g / m 2 , ...

Embodiment 3

[0045] The slope length of the storage yard 1 in the third embodiment of the present invention is 80m, ungraded, and the slope is all above 55°, and the slope of the storage yard 1 has a high degree of looseness, and there is no soil layer, which seriously restricts the normal growth of plants. . A kind of slope ecological restoration method provided by this embodiment is similar to the slope ecological restoration method in Embodiment 1 and Embodiment 2, and the same parts will not be repeated, and the difference is that in step S1, the stockyard 1 Repairing is a four-level stepped slope, and the slope length of each level is 20m; the volume fraction A of the fermented sludge during the preparation of the filling material 11 in step S23 is 35%, and the volume fraction B of the light matrix is 30% %, the volume fraction C of the loam is 35%, and the addition of the water-retaining agent is 400g; In step S3, the spray thickness of the seed layer 6 is 4cm, and the volume fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com