Layered intravascular stent forming system and method based on electrostatic direct writing and electrospinning technology

An electrospinning technology and a vascular stent technology, which are applied in the fields of mechanical manufacturing and biomanufacturing, can solve problems such as the difficult three-layer structure of the stent, and achieve the effects of high stent strength, improved efficiency, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

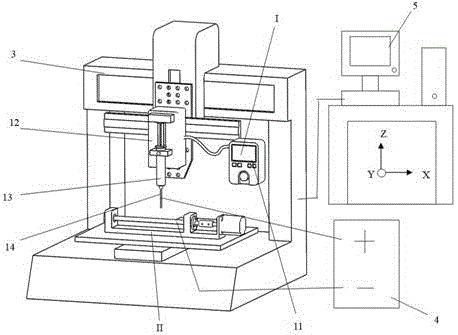

[0030] see Figure 1~Figure 3, a layered vascular stent forming system based on electrostatic direct writing and electrospinning technology, comprising a feeding system I, a spinning collection system II, a three-axis motion platform 3, a power supply 4 and a computer control system 5, characterized in that: The feeding system I is arranged on the Z-axis slider of the three-axis moving platform 3; the spinning collection system II is fixedly installed on the XY-axis platform of the three-axis moving platform 3, so that the syringe needle 14 of the feeding system I The axis is perpendicular to the axis of the mandrel 22 of the spinning collection system II; the positive pole of the power supply 4 is connected to the metal part of the syringe needle 14, and the negative pole is connected to the metal part of the mandrel 22; the computer control system 5 and the three-axis motion platform 3 Electrically connected to control the three-dimensional movement of the three-axis motion ...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0033] Described feeding system 1 comprises micropump controller 11, micropump actuator 12, syringe piston barrel 13 and syringe needle 14; Described micropump actuator 12 is fixed on the Z-axis slide block of three-axis motion platform 3 , the Z-axis slider drives the micropump actuator 22 to move along the Z-axis direction, the syringe piston cylinder 13 is fixedly mounted on the micropump actuator 12, the syringe needle 14 is fixed on the bottom end of the syringe piston cylinder 13, and the micropump The actuator 12 is driven by the micropump controller 11 to push the syringe piston barrel 13 to extrude the spinning material.

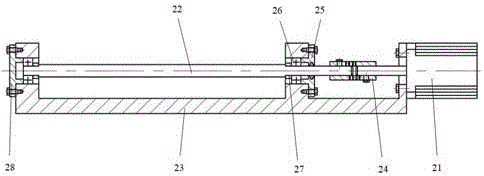

[0034] The spinning collection system II consists of a stepper motor 21, a mandrel 22, a spinning collection frame 23, a shaft coupling 24, a first bearing end cover 25, a deep groove ball bearing 26, a sleeve 27 and a second bearing The end cov...

Embodiment 3

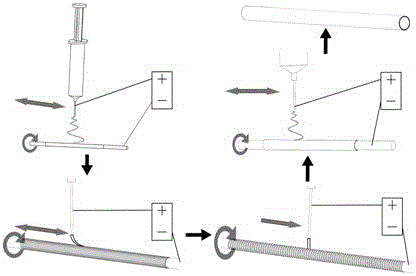

[0037] A layered vascular stent forming method based on electrostatic direct writing and electrospinning technology, using the above-mentioned layered vascular stent forming system based on electrostatic direct writing and electrospinning technology to operate, the operation steps are as follows:

[0038] 1) The innermost layer of the formed vascular stent: adjust the distance between the syringe needle 14 and the mandrel 22 to meet the conditions for electrospinning, the positive pole of the power supply 4 is connected to the metal part of the syringe needle 14, and the negative pole is connected to the mandrel 22 The metal part, so that a high-voltage electric field is formed between the syringe needle 14 and the mandrel 22. Under the joint action of the thrust of the micropump actuator 12 and the electrostatic field force, the syringe needle 14 ejects nano-scale fiber filaments, and at the same time The motor 21 drives the mandrel 22 to rotate at a constant rate, and the XY ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com