System and method for catalytic purification and treatment of coal chemical raw synthesis gas

A crude synthesis gas, catalytic purification technology, applied in the direction of catalytic treatment of combustible gas, gasification process, combustible gas purification/transformation, etc., can solve the problems of cracking, high energy consumption, unfavorable natural gas process, etc. , the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

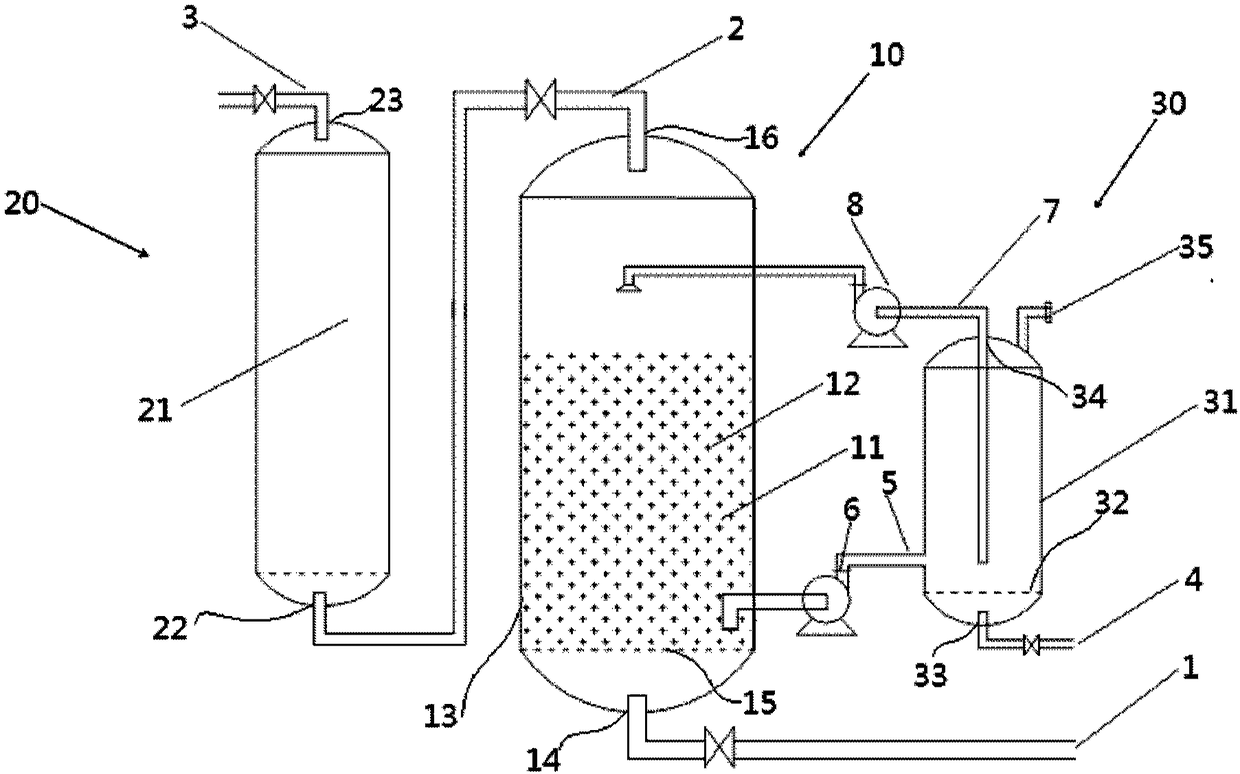

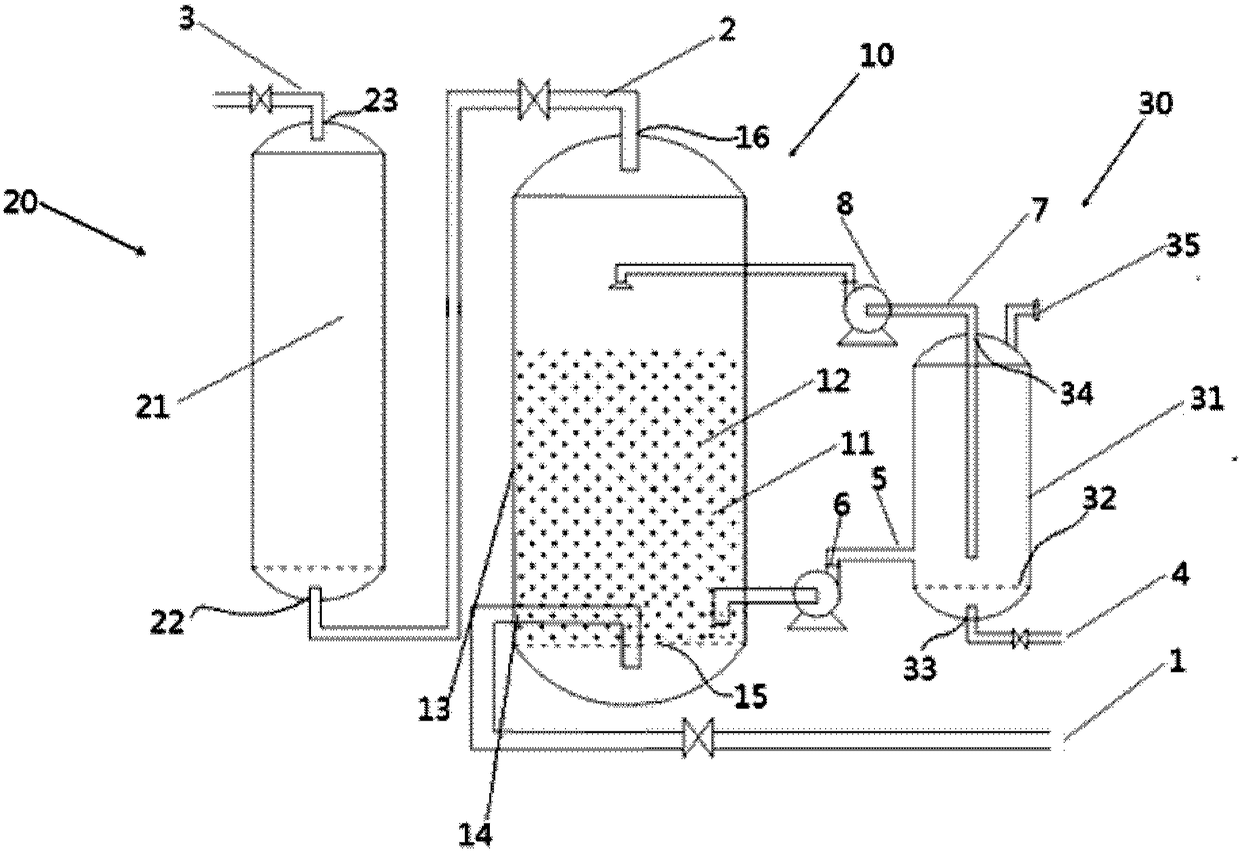

[0039] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0040] The inventive idea of the present invention is to reduce the tar, phenols, etc. Harmful substances, which will greatly reduce the load of subsequent further purification and cooling treatment, and at the same time greatly reduce the amount of coal chemical wastewater.

[0041] Therefore, the present invention uses a salt mixture with good thermal conductivity, heat storage and catalytic performance as the molten salt, and passes all ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com