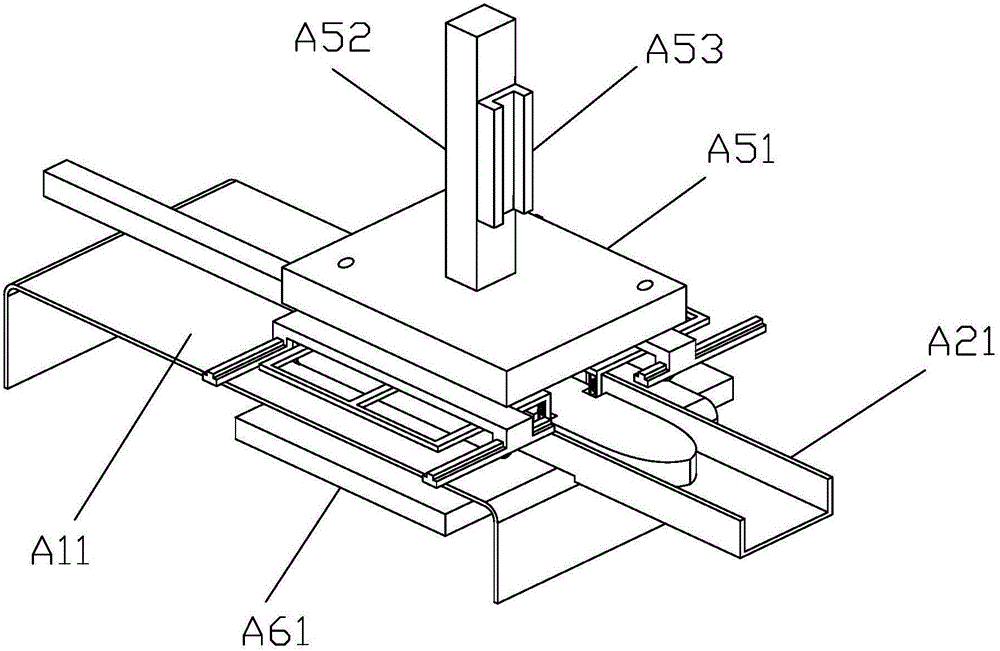

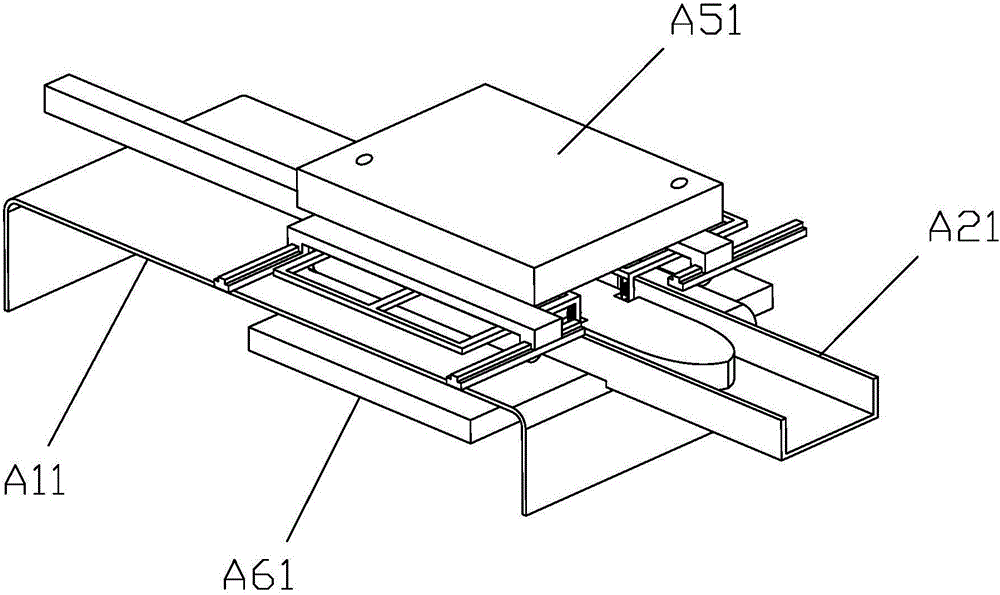

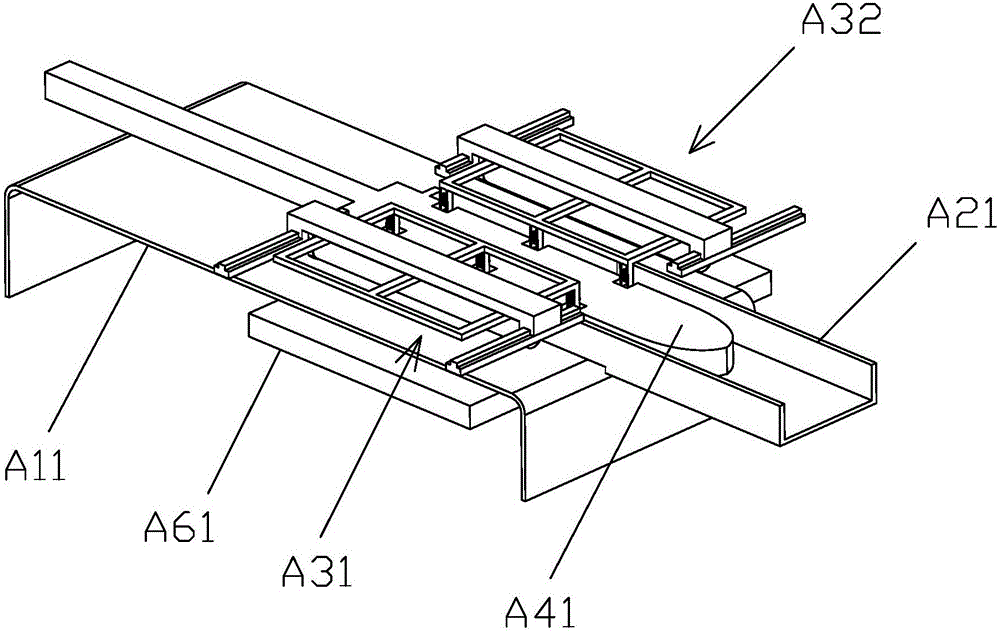

Equipment for treating culmsheath wastes in combination with hair removal device, steaming device and flattening device

A technology of hair removal device and cooking device, which is applied in wood treatment, mechanical equipment, wood treatment details, etc., and can solve the problems that the flattening efficiency cannot meet the actual production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

[0039] Bamboo shell is also known as culm sheath, bamboo sheath, bamboo shoot shell, without removing the sheath leaves ( Figure 16 The schematic diagram of the structure of the bamboo shell at b place) after flattening is as follows Figure 16 As shown, the end where the bamboo shell is connected with the sheath ring (rod ring) is called the head end of the bamboo shell, and the end where the sheath leaves grow on the bamboo shell Z1 is called the tail end of the bamboo shell, and the end of the bamboo shell that grows hairy The surface is called the outer surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com