Hemispherical dynamic pressure bearing part grinding tool and grinding method

A technology of dynamic pressure bearing and grinding method, which is applied in the direction of grinding device, grinding machine tool, manufacturing tool, etc., to achieve the effect of stable processing state, high processing quality and meeting the requirements of working gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

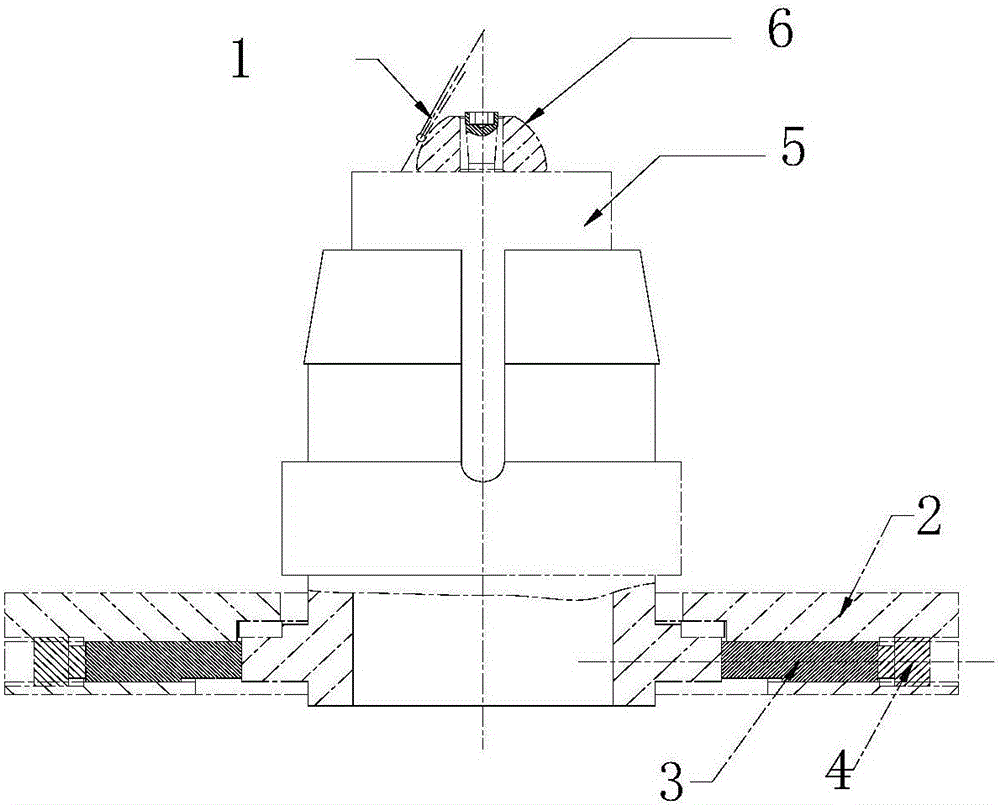

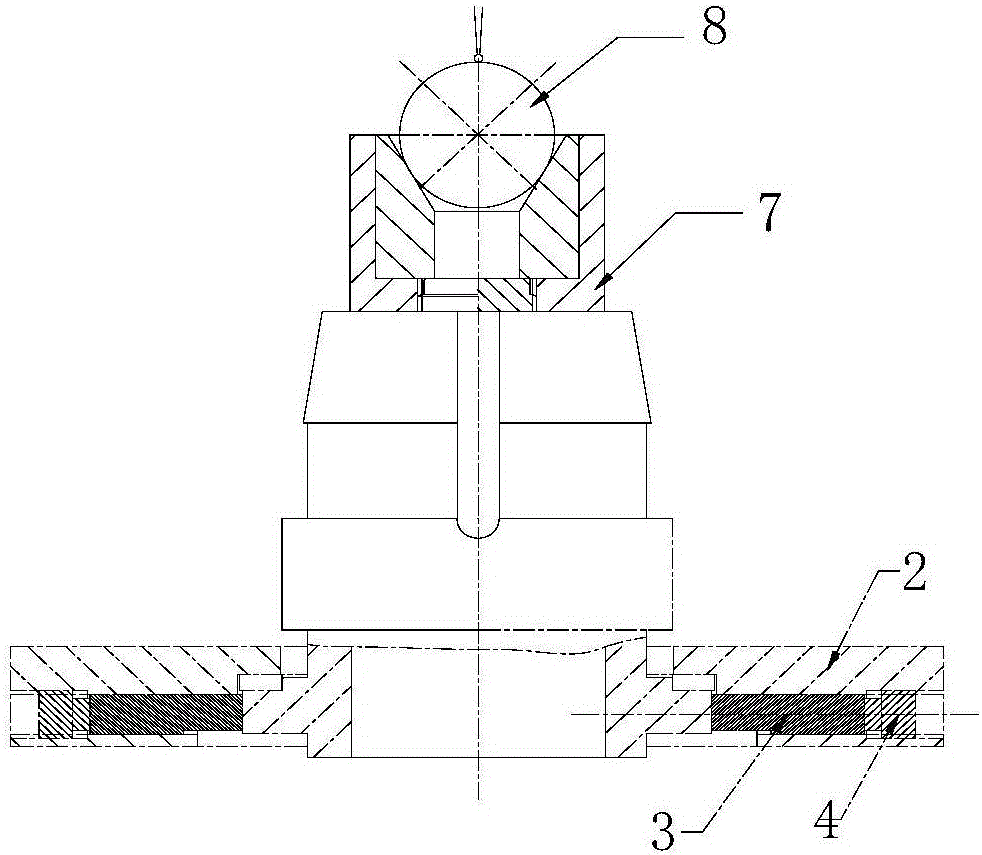

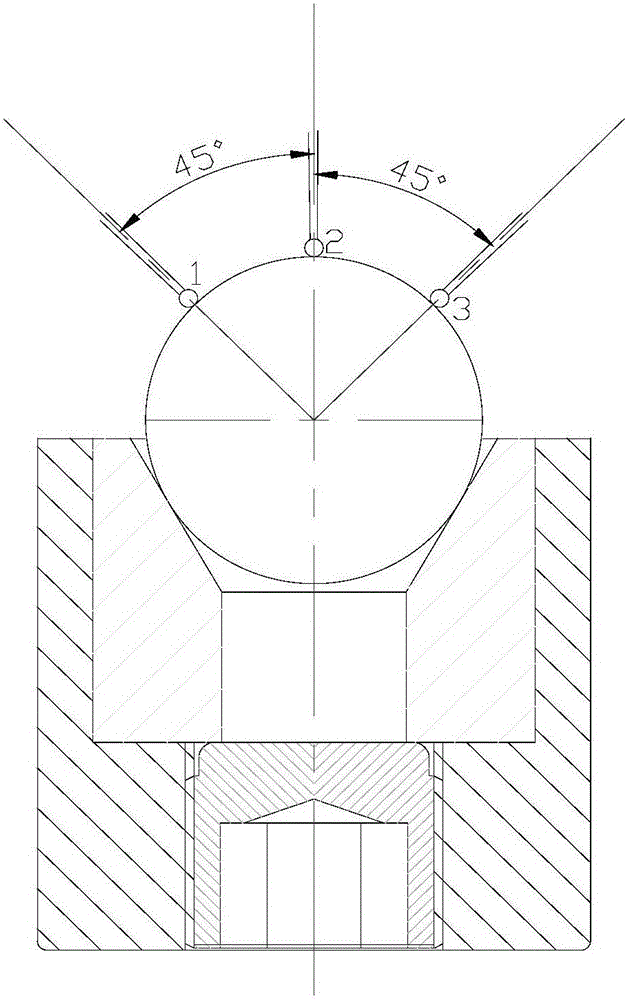

[0047] Such as figure 1 and figure 2 The shown hemispherical dynamic pressure bearing part grinding tooling includes a transmission seat 2, a tooling spindle 5 and a positioning block 7; four pins 3 are evenly distributed around the transmission seat 2, and four pins 3 are arranged on the outside of the four pins 3 respectively. A hexagon socket screw 4; the bottom end of the tooling main shaft 5 is arranged at the center of the transmission seat 2, and the top of the tooling main shaft 5 is provided with a positioning block 7; the positioning block 7 is provided with a bell mouth for placing steel balls, and the outer sleeve of the tooling main shaft Attached with fastening device.

[0048] The method for grinding hemispherical dynamic pressure bearing parts includes the following steps:

[0049] 1) Adjust the precision of the center of rotation of the grinding machine spindle:

[0050] 1.1) Place the vertical main shaft of the tooling concentrically in the drive seat 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com