Pocket vertical grinding machine

A vertical grinding machine and pocket-sized technology, applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of wasting energy and resources, waste, etc., to reduce energy consumption, improve efficiency, improve quality and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

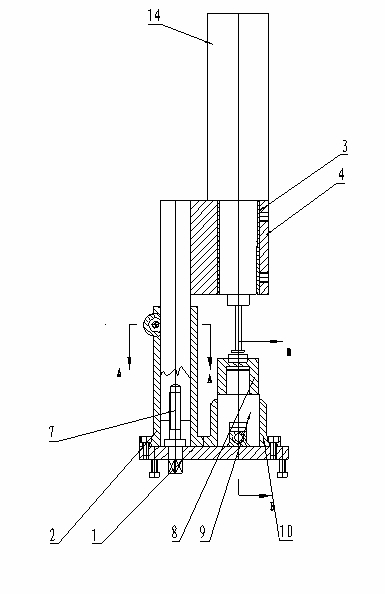

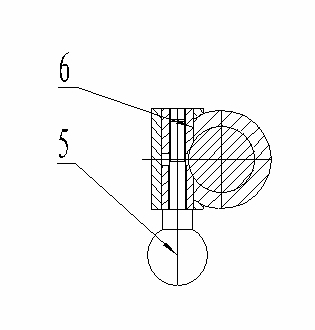

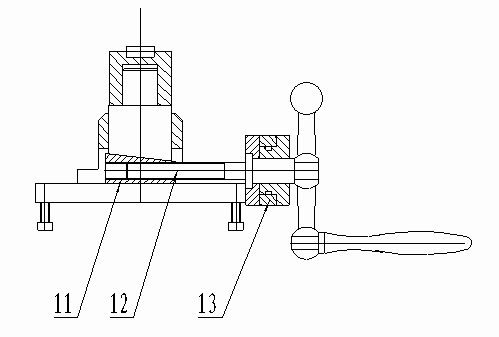

[0012] Pocket vertical grinding machine, including base 1, column 2, open tapered sleeve 3, grinding head bracket 4, clamping bolt 5, clamping sleeve 6, adjusting bolt 7, workpiece cover 8, lifting seat 9, fixed seat 10, inclined Block 11, leading screw 12, scale ring 13, electric grinding head 14, described electric grinding head 14 is clamped on the grinding head support 4 by open taper sleeve 3, and grinding head support 4 can rotate around column 2; 2 is provided with clamping sleeve 6, clamping sleeve 6 is equipped with clamping bolt 5; workpiece sleeve 8 is fixed on the lifting seat 9, and lifting seat 9 is fixed on the fixing seat 10; 11 matched chute, leading screw 12 links to each other with slanting block 11, and slanting block 11 joins with lifting seat 9; The end of leading screw 11 is provided with scale ring 13 and handle.

[0013] The total weight of the machine tool is 5Kg. The electric grinding head adopts the electric tool straight grinder (electric grinder) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com