Vertical height-adjustable drilling equipment

A technology of vertical height and drilling device, applied in driving devices, feeding devices, drilling/drilling equipment, etc., can solve problems such as affecting workers' health, dumping, and easy inhalation of powder particles into workers, reducing labor costs. Labor intensity, easy to use, good drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

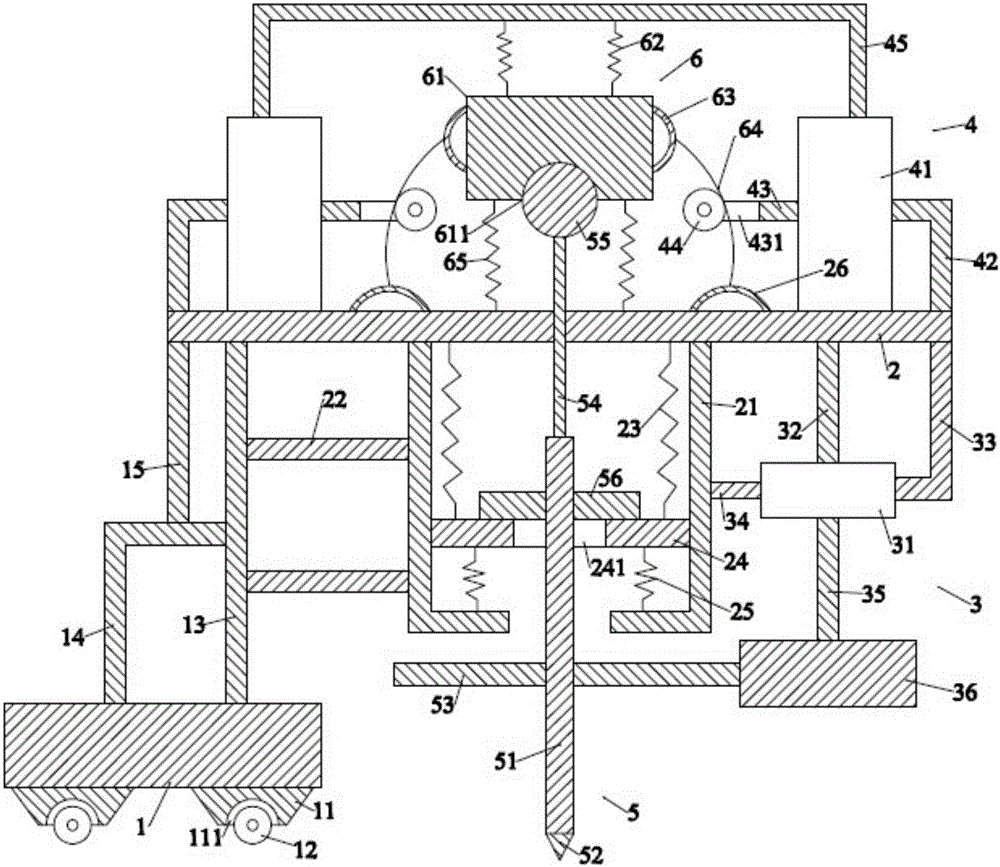

[0018] Such as figure 1 As shown, the vertical height adjustable drilling device of the present invention includes a bottom plate 1, a horizontal plate 2 above the bottom plate 1, a motor device 3 below the horizontal plate 2, and a left and right side above the horizontal plate 2. The cylinder device 4, the abutment device 6 between the cylinder devices 4 and the drilling structure 5 below the abutment device 6.

[0019] Such as figure 1 As shown, the base plate 1 is a cuboid, and the base plate 1 is placed horizontally. The base plate 1 is provided with a first support block 11 below it, a first roller 12 below the first support block 11, and a first roller 12 located below the first support block 11. The first support bar 13 above the first support block 11 , the first support bar 14 on the left side of the first support bar 13 , and the second support bar 15 above the first support bar 14 . The first support block 11 is provided with two and is respectively located on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com