Preparation method for hydrophilic polyvinylidene fluoride (PVDF) antibacterial ultrafiltration membrane

A polyvinylidene fluoride and ultrafiltration membrane technology, which is applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of large amount of silver salt, increased modification cost, and difficulty in controlling the uniformity of the membrane to achieve antibacterial significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

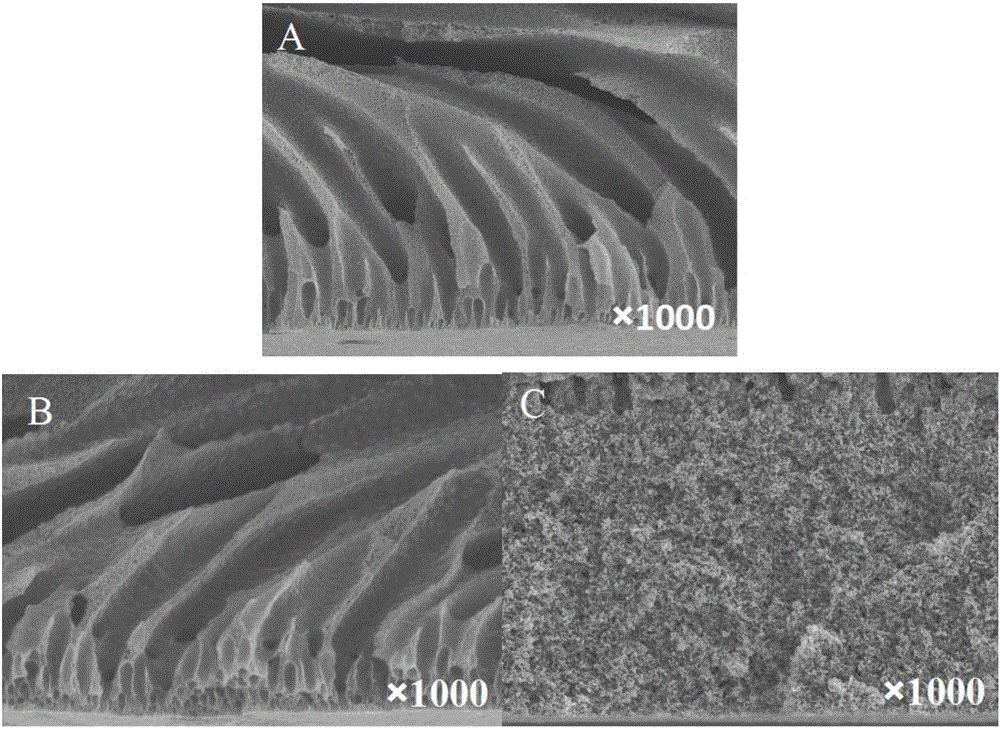

Embodiment 1

[0023] (1) Prepare a uniform dispersion: weigh 0.10g GO and disperse it in 80.9g DMF, add 1.5g PVP after ultrasonic dispersion for 2h, continue ultrasonication for 0.5h, then add 0.5g AgNO 3 Ultrasound 0.5h to form a uniform dispersion.

[0024] (2) Preparation of pre-reaction solution at room temperature: Add 1.0g of F127 to the above-mentioned uniform dispersion at the same time with magnetic stirring, and then add 16g of PVDF after stirring evenly, and stir for 6 hours at room temperature to form a uniform and transparent pre-reaction solution.

[0025] (3) Preparation of casting solution by in-situ thermal reduction: the pre-reaction solution was vacuum-degassed for 20 minutes and sealed, then reacted in an oil bath at 60°C for 80 hours to prepare a casting solution.

[0026] (4) Preparation of antibacterial film by immersion precipitation phase inversion method: scrape the above-mentioned casting solution on a clean glass plate, let it stand in the air for 10 seconds, the...

Embodiment 2

[0028] (1) Prepare a uniform dispersion: weigh 0.15g GO and disperse it in 78.4g DMF, add 1.5g PVP after ultrasonic dispersion for 2 hours, continue ultrasonication for 1 hour, then add 0.45g AgNO 3 Ultrasound 0.5h to form a uniform dispersion.

[0029] (2) Preparation of pre-reaction solution at room temperature: Add 1.5g of F127 to the above-mentioned uniform dispersion at the same time with magnetic stirring, and then add 18g of PVDF after stirring evenly, and stir for 8 hours at room temperature to form a uniform and transparent pre-reaction solution.

[0030] (3) Preparation of casting solution by in-situ thermal reduction: after vacuum degassing for 5 minutes and sealing, the pre-reaction solution was reacted in an oil bath at 40°C for 10 hours to prepare casting solution.

[0031] (4) Preparation of antibacterial film by immersion precipitation phase inversion method: scrape the above-mentioned casting solution on a clean glass plate, let it stand in the air for 10 seco...

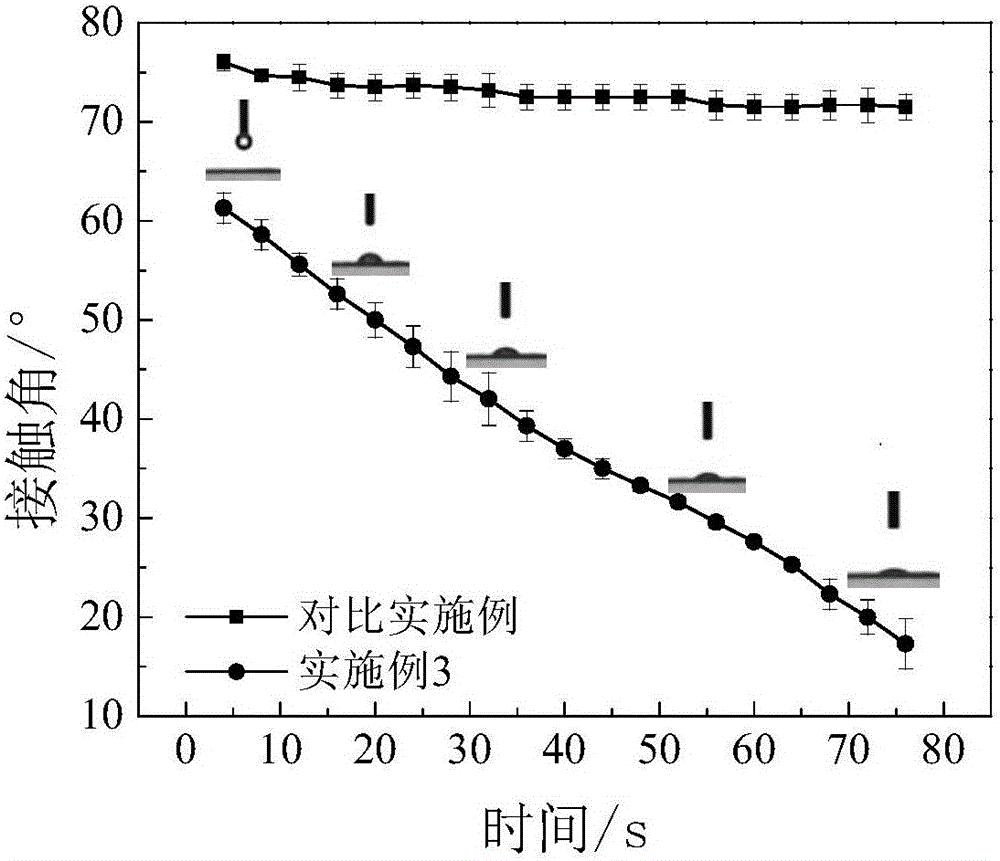

Embodiment 3

[0033] (1) Prepare a uniform dispersion: weigh 0.65g GO and disperse it in 76.6g DMF, add 1.8g PVP after ultrasonic dispersion for 2h, continue ultrasonication for 0.5h, then add 1.25g AgNO 3 Ultrasound 0.5h to form a uniform dispersion.

[0034] (2) Preparation of pre-reaction solution at room temperature: Add 1.8g of F127 to the above uniform dispersion at the same time with magnetic stirring, and then add 18g of PVDF after stirring evenly, and stir for 6 hours at room temperature to form a uniform and transparent reaction solution.

[0035] (3) Preparation of casting solution by in-situ thermal reduction: the pre-reaction solution was vacuum-degassed for 10 minutes and sealed, then reacted in an oil bath at 50° C. for 10 hours to prepare a casting solution.

[0036] (4) Preparation of antibacterial film by immersion precipitation phase inversion method: scrape the above-mentioned casting solution on a clean glass plate, let it stand in the air for 10 seconds, then immerse i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com