Automated sowing streamline for breeding plug tray

The technology of seedling tray and assembly line is applied in the directions of sowing, single-seed planter, planter parts, etc., which can solve the problems of increasing labor intensity, increasing seedling cost, reducing production efficiency, etc. cost, improve seeding quality and efficiency, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

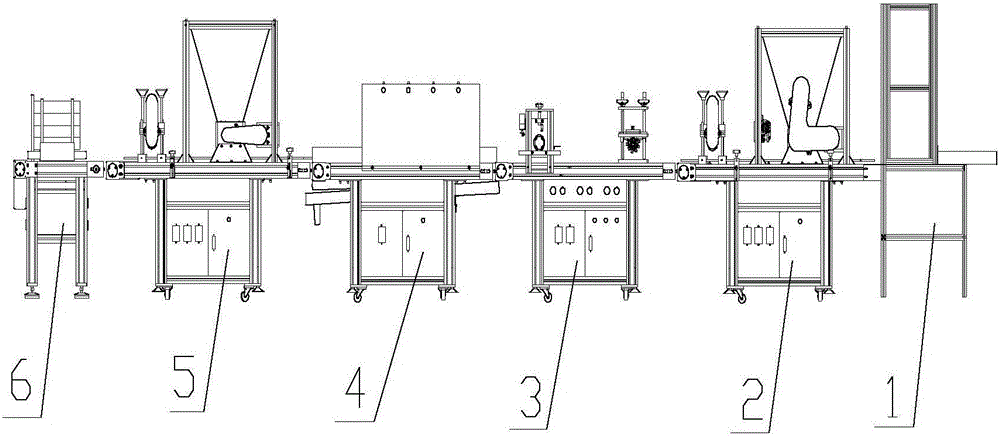

[0035] Such as figure 1 As shown, an automatic seedling tray sowing line, the seeding assembly line is fixed with a seedling tray upper plate device 1, a substrate laying device 2, a precision drum seeding device 3, a spray device 4, a substrate covering device 5 and a seedling cultivation hole in sequence. A tray stacking device 6, a seedling tray is placed above the seedling tray upper tray device 1, and the seedling tray is pushed along the conveyor belt to the sowing line. The working efficiency of the assembly line of the present invention is 10 times that of the traditional artificial seedling raising mode, reduces the labor cost by two-thirds, and can significantly improve the quality of seedling raising. The operation is simpler, the work efficiency and quality are higher, the commonality of parts is better, the reliability and safety are higher, and the market prospect is very broad.

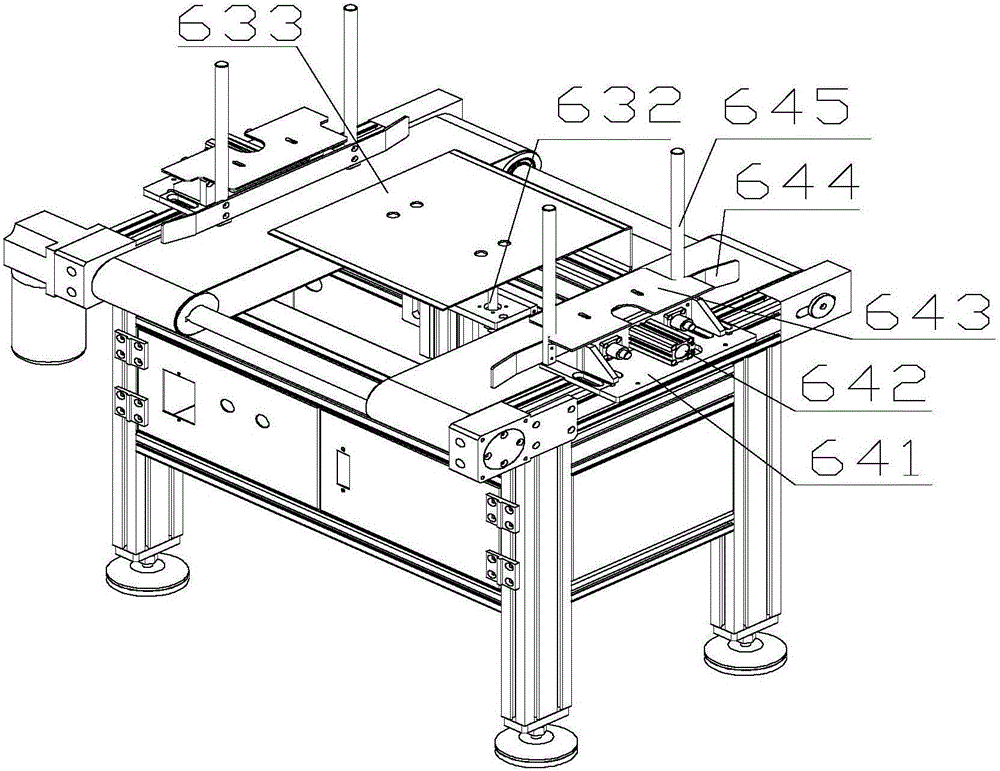

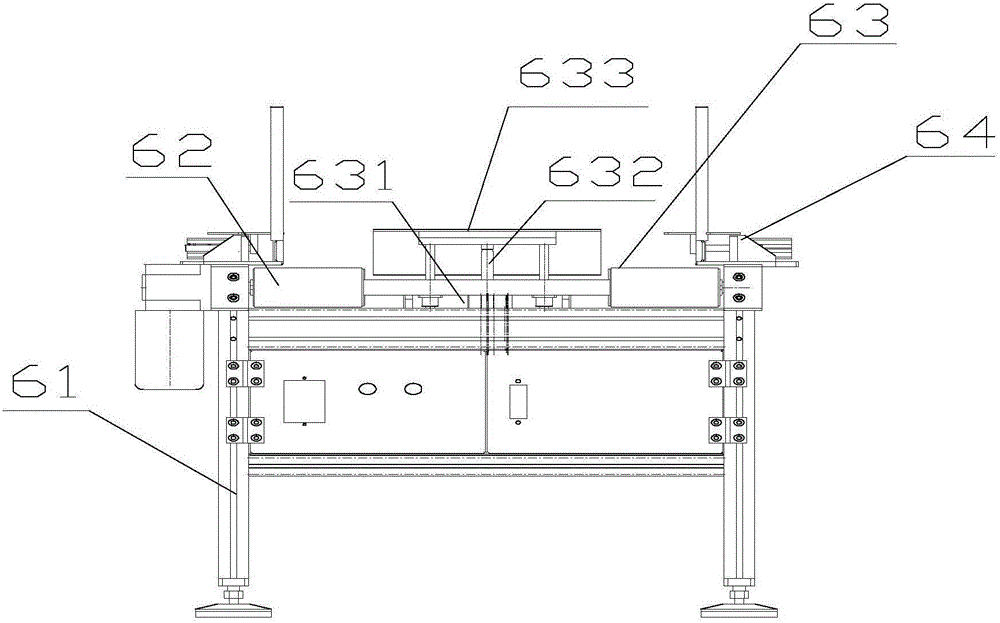

[0036] Such as figure 2 , image 3 with Figure 4As shown, the seedling tray p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com