Optimised timepiece barrel

A barrel and clockwork technology, applied to clocks, clocks, mechanically driven clocks, etc., can solve problems such as wear and damage to the pivot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention relates to the field of timepiece mechanisms comprising springs in frictional contact, and more particularly to mainspring barrels and striking barrels.

[0033] In order to prevent wear problems in pivoting areas, wear-resistant treatments that provide high hardness to the material must be avoided on the surfaces where pivoting occurs (spindle bore, bearing surfaces), whether these are thermal or induction treatments, surface treatments, coatings , spraying or other treatments, all of which are referred to below as "treatments". More specifically, the invention advantageously avoids depositing even a limited amount of DLC or any other PVD / CVD coating (and similar method), ensuring impermeability to the carrier gas during the process for depositing the adhesion layer and sublayers.

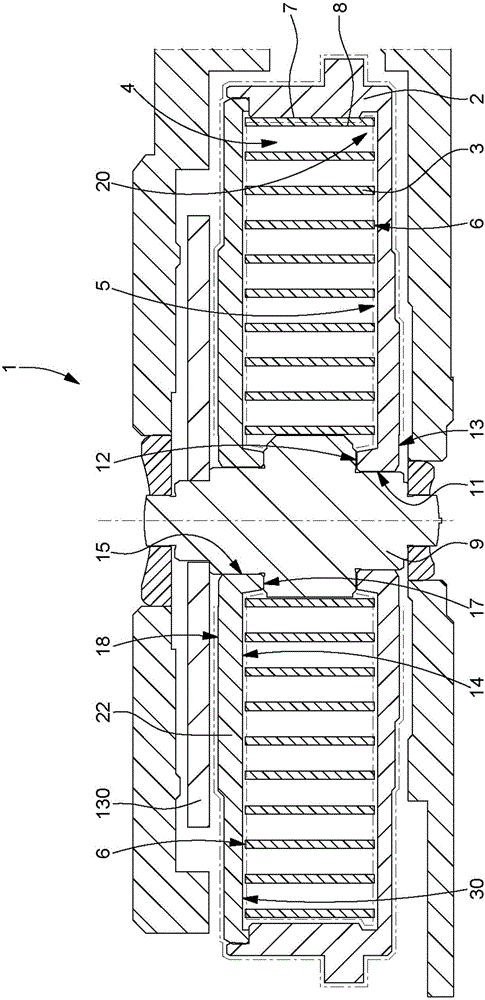

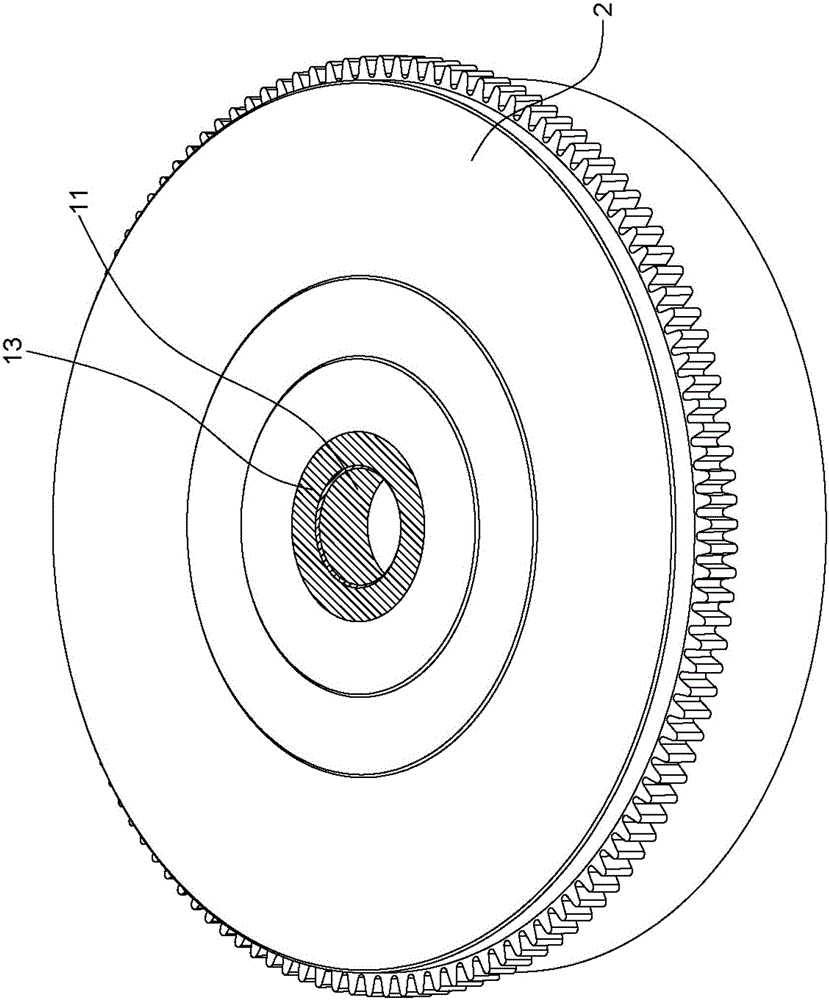

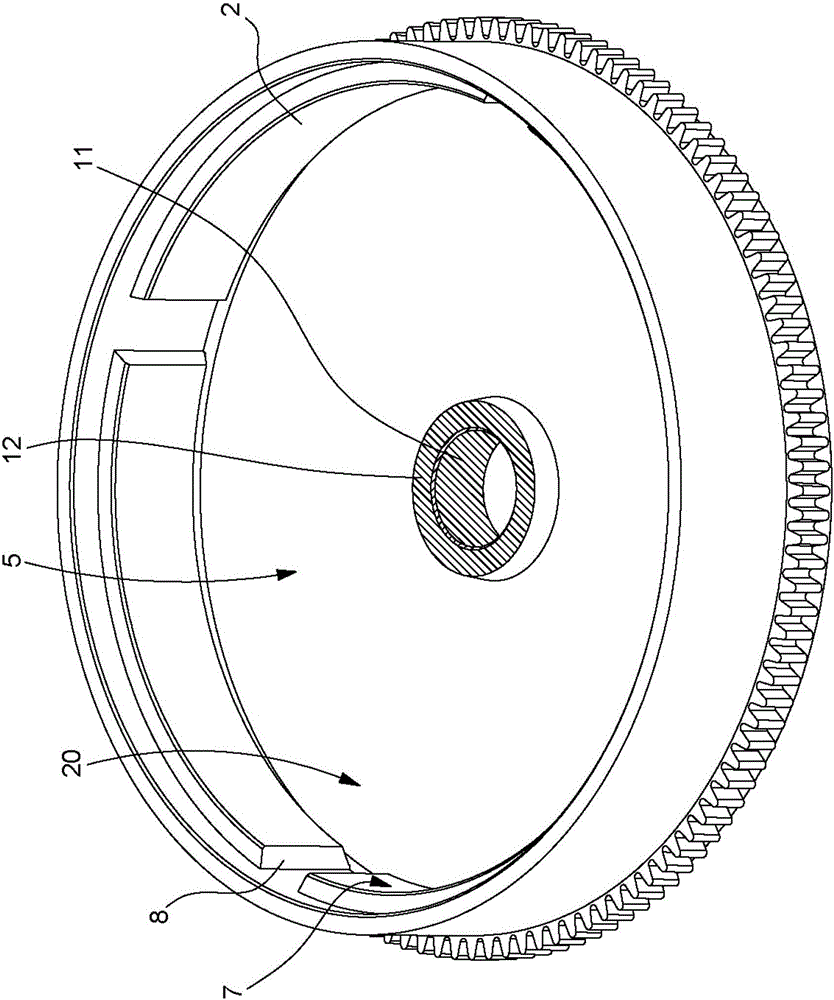

[0034] The invention thus relates to a timepiece barrel 1 comprising at least one barrel 2 for receiving at least one helical winding barrel in a cavity 4 partially d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com