Gas distributer for a convective dryer having improved radial gas velocity control

A gas distributor, gas velocity technology, applied in the direction of drying solid materials, heating to dry solid materials, dryers, etc., can solve the problems of unrealizable, low radial velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

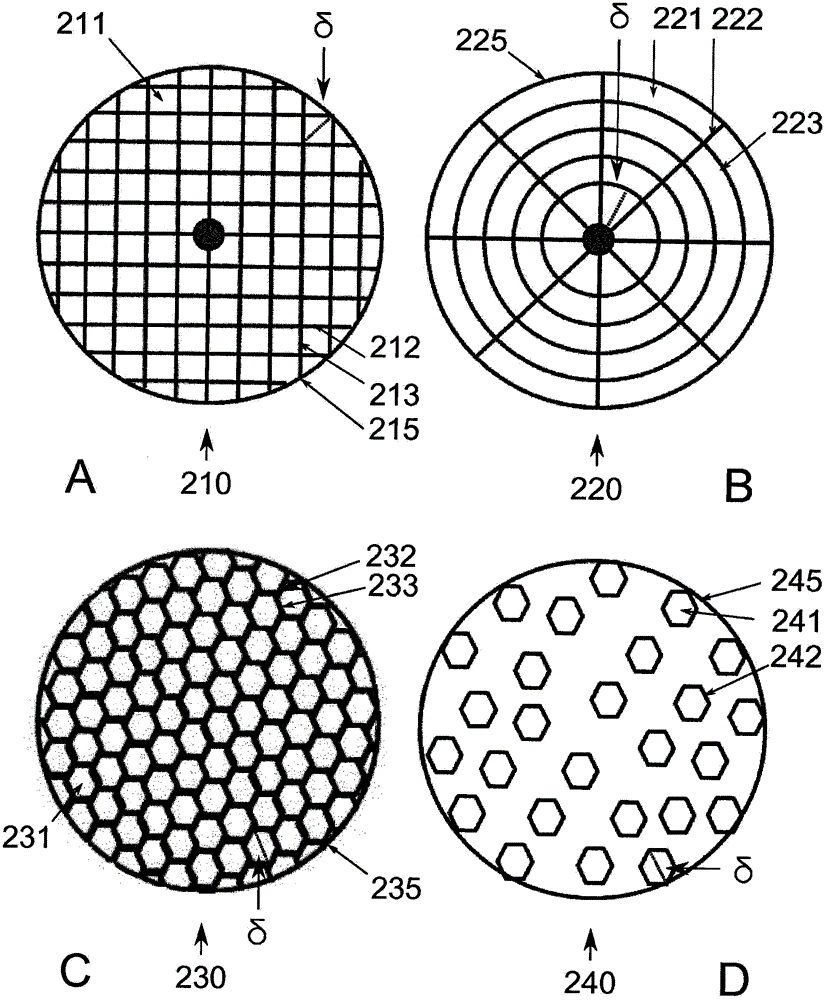

[0029] As stated above, it is important to the present invention to provide a drying gas jet for a convective dryer with improved radial control and axial alignment at the outlet surface of the associated gas distributor.

[0030]The inventors of the present invention have realized that improvements to jet flow stability and calibration can be achieved in a simple manner by inserting a flow calibrator according to the invention into the flow path of the drying gas, wherein the flow calibrator can be placed in the In or upstream of the gas distributor. For example, the flow calibrator according to the invention can be arranged in a system for convective drying or in a convective dryer upstream of said gas distributor, for example, in atomizing devices and heaters, coolers, filters, mixing between inserts or valves and still have a beneficial effect on the radial velocity component of the drying gas flow. It is therefore a further object of the present invention to provide a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com