Ceramic composite electronic cigarette heater

A ceramic composite and heater technology, applied in the direction of ohmic resistance heating parts, heating element shapes, etc., can solve the problems of electronic cigarette liquid leakage, affecting the service life of the resistance wire, carbonization of the liquid-conducting cotton 102, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

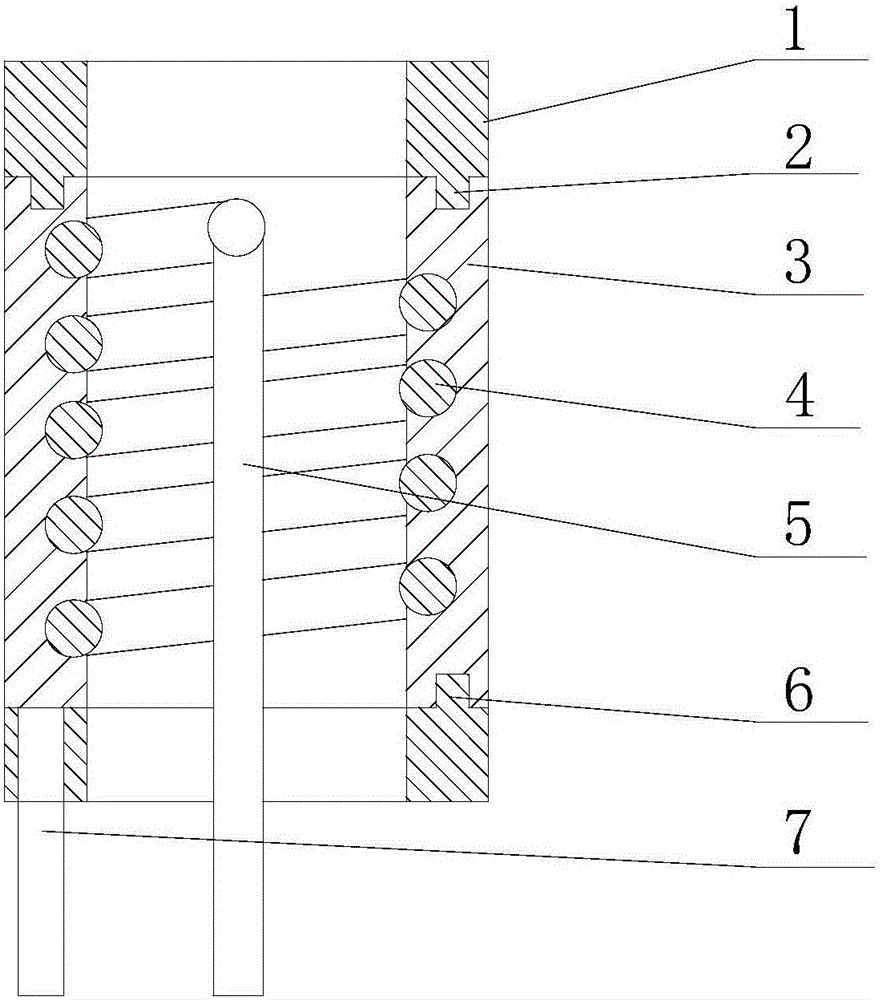

[0029] Such as figure 1 , figure 2 As shown, the ceramic composite electronic cigarette heater of this embodiment has a tubular heater structure. It consists of two parts, one of which is a spiral heating wire as the heating component 4, and the other part is a ceramic coating 3 for fixing and embedding the heating component 4, and the ceramic coating 3 is a cylindrical tube. The spiral heating wire is located at the inner tube wall of the ceramic coating 3 and protrudes from the inner tube wall. The purpose of this is to achieve a gradual increase in the temperature of the ceramic composite electronic cigarette heater from the outer wall to the inner wall and increase the atomization effect. The main body part of the middle section of the ceramic coating layer 3 is sintered with a ceramic material with micropores, such as corundum. The purpose of providing these micropores is to make the ceramic coating layer 3 absorb the e-cigarette liquid, thereby realizing the penetratio...

Embodiment 2

[0038] Such as image 3 Shown is a schematic cross-sectional structure diagram of Embodiment 2 of the present invention. The heating component 4 is an electric heating wire wound in a spiral shape. The whole heating wire is spirally covered with a microporous ceramic coating 3, and both ends of the heater are The metal ring dense connectors 1 and 6 are provided, and the dense connectors 1 and 6 are provided with a connecting post 2, which is arranged inside the microporous ceramic coating layer 3. The metal ring dense connectors 1 and 6 are connected to the microporous ceramic package. The coating 3 is sintered and molded together. In this embodiment, the wiring pins 5 and 7 at both ends of the heating component 4 are electrically connected to the dense connectors 1 and 6 at both ends, so that the connectors 1 and 6 at both ends can be used as the connecting electrodes of the heater. The metal connecting pieces 1 and 6 are arranged at both ends. Since the metal pieces can be ea...

Embodiment 3

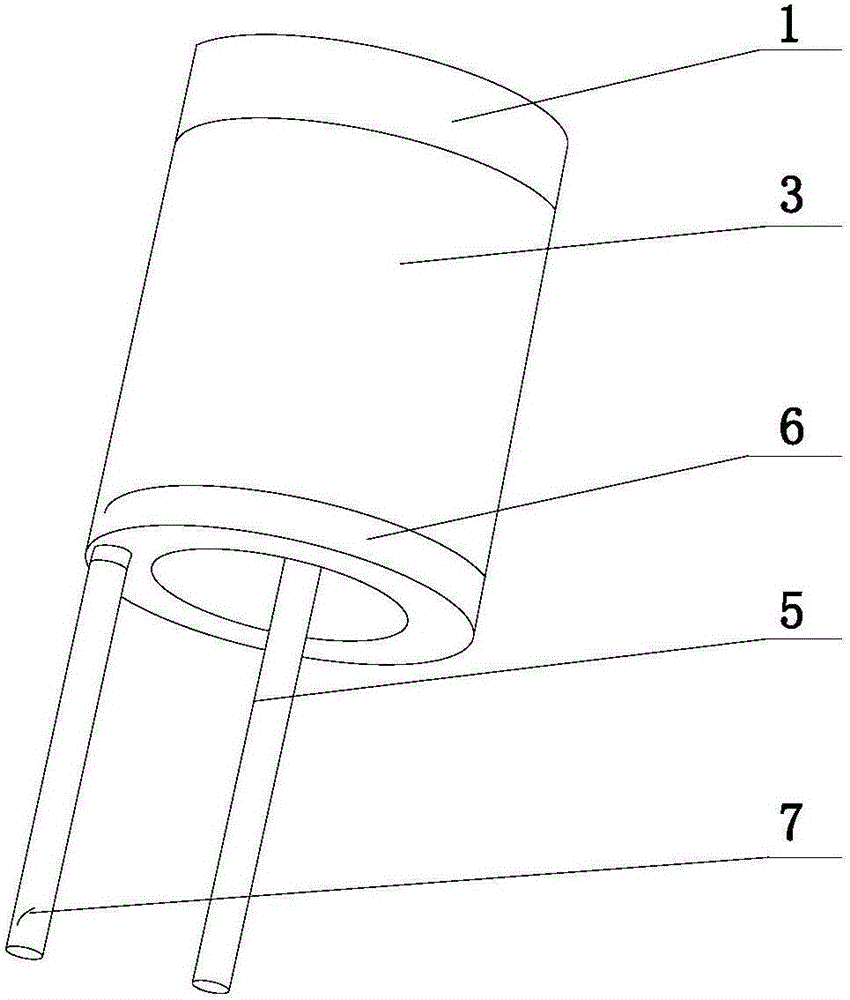

[0040] Such as Figure 4 , Figure 5 Shown are a perspective view and a cross-sectional view of Embodiment 3 of the present invention. It is a spiral heater, the heater structure is coated with ceramic coating on the heating wire. The heating element 4 of the heater body is an electric heating wire wound into a spiral shape. A thin ceramic coating layer 3 is provided on the outer surface of each part of the single heating wire. The ceramic coating layer 3 is used to dip the spiral heating wire It is formed by sintering after coating ceramic material. During production, the ceramic coating 3 is made of dense ceramic, and the connecting pins 5 and 7 of the heating component 4 are exposed outside the ceramic coating 3. The advantage of the spiral heater is that the whole heater is still spiral, but its outer surface is insulated ceramic. It can be used with liquid-conducting substances of various materials, and it can also be directly installed on the heated water-based liquid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com