Miniature loudspeaker and preparation method of miniature loudspeaker

A micro-speaker, injection molding technology, applied in the directions of loudspeakers, sensors, electrical components, etc., can solve the problem of low efficiency and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention will be further described

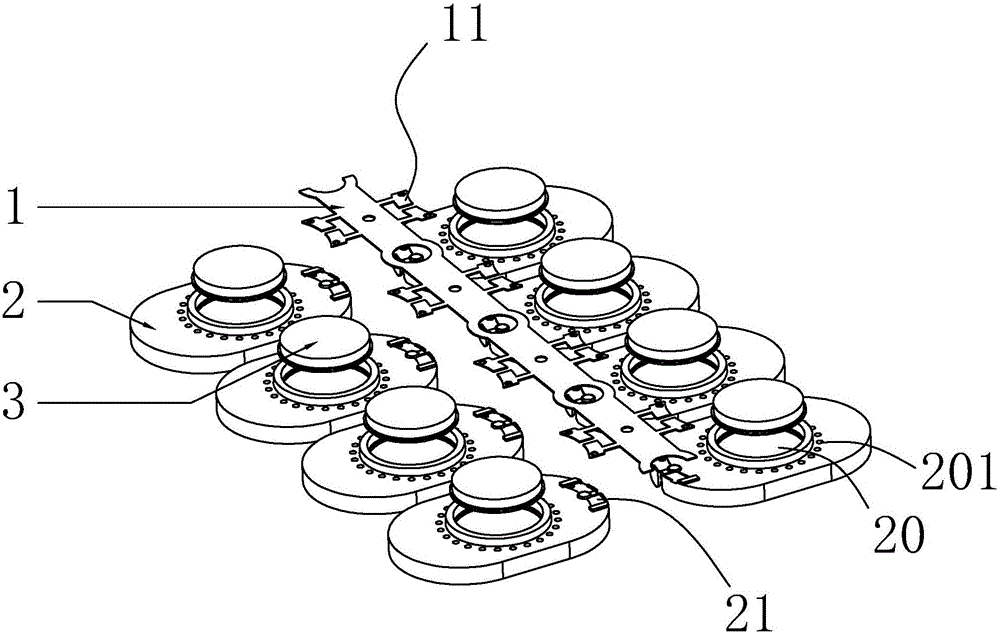

[0015] As shown in the figure, a micro-speaker includes a plastic bracket 2, and a magnetic circuit system fixed on the plastic bracket, a voice coil, a diaphragm and a pad 11 for electrical connection.

[0016] Wherein, the magnetic circuit system includes a U-cup 3 fixed on the plastic bracket 2, a magnet fixed in the U-cup 3, and a washer attached to the magnet. The magnetic circuit system is used to provide a magnetic field, and the voice coil is electrically connected through the welding pad. After being energized, under the action of the magnetic field generated by the magnetic circuit system, it is driven by the Lorentz force to move up and down, and further drives the diaphragm to vibrate and produce sound. The plastic bracket is a flat plate structure with a sound hole 20 in the center, the U-cup 3 is set in the center of the plastic bracket 2 , and the opening of the U-cup 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com