A tuyere structure and manufacturing method thereof

A technology of tuyere and ventilation duct, which is applied in the field of vents, which can solve the problems of not being able to fit each other, the sealing effect, dust entering the room, and the louver blades being easily blown, etc., to achieve the effect of firm welding effect, increased efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

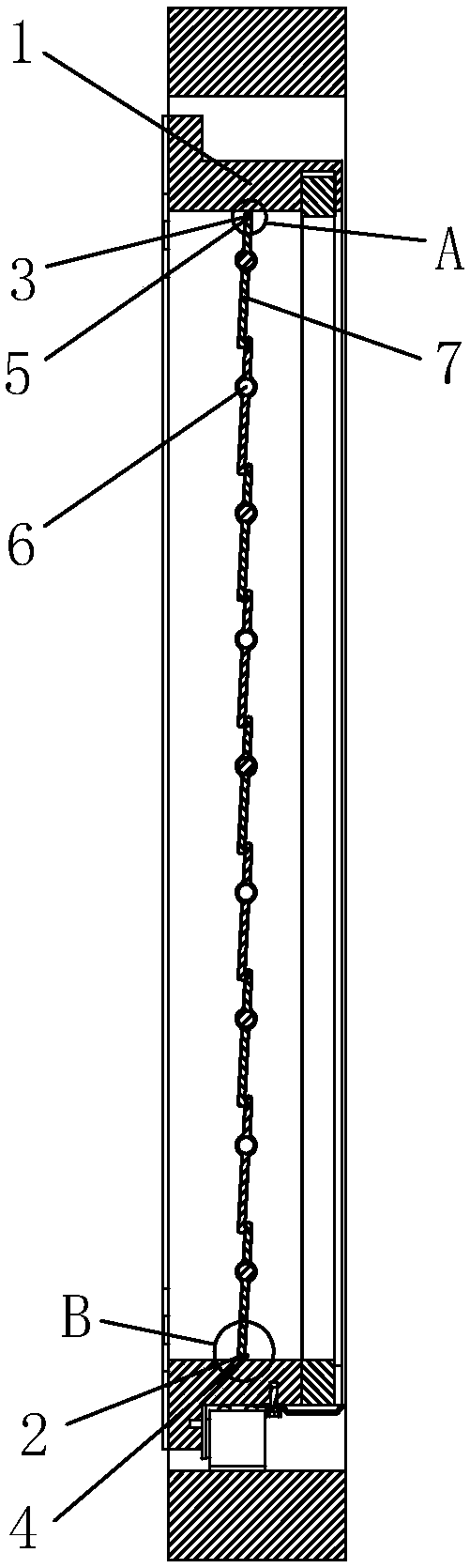

[0034] Embodiment 1: A tuyere structure, refer to Figure 4 , including a frame body 1 arranged around the ventilation duct, the shape of the frame body 1 is a cuboid, a plurality of louver blades 7 are arranged and distributed in the frame body 1 in its length direction, and a plurality of rotating shafts are arranged in the width direction of the frame body 1 6. The two ends of the rotating shaft 6 are rotationally connected with the frame body 1. Each rotating shaft 6 is correspondingly equipped with a louver 7. When the rotating shaft 6 is rotated, the louver 7 rotates around the rotating shaft 6. After the rotation of a plurality of louvers 7, the Ventilation ducts are closed or open;

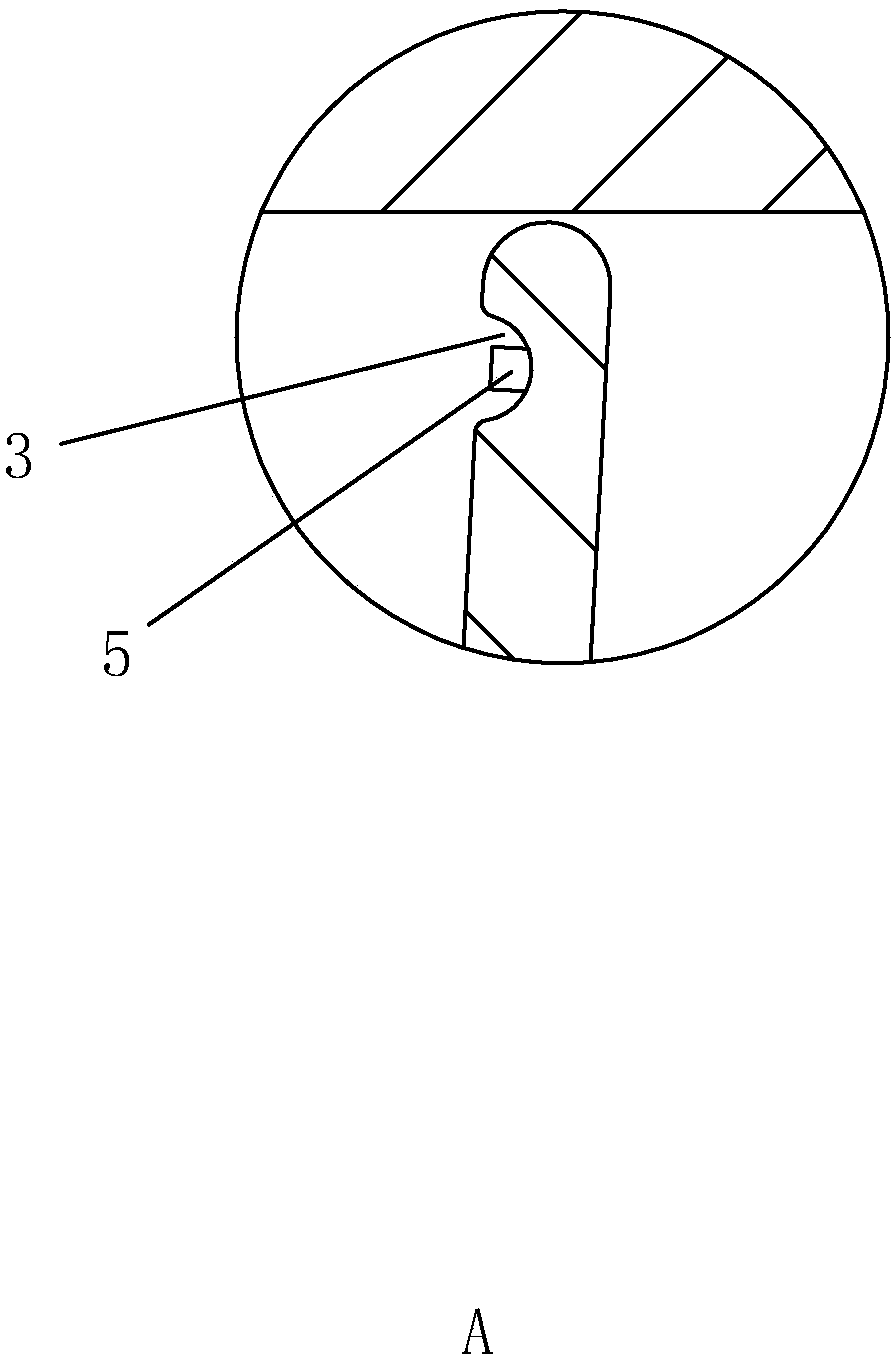

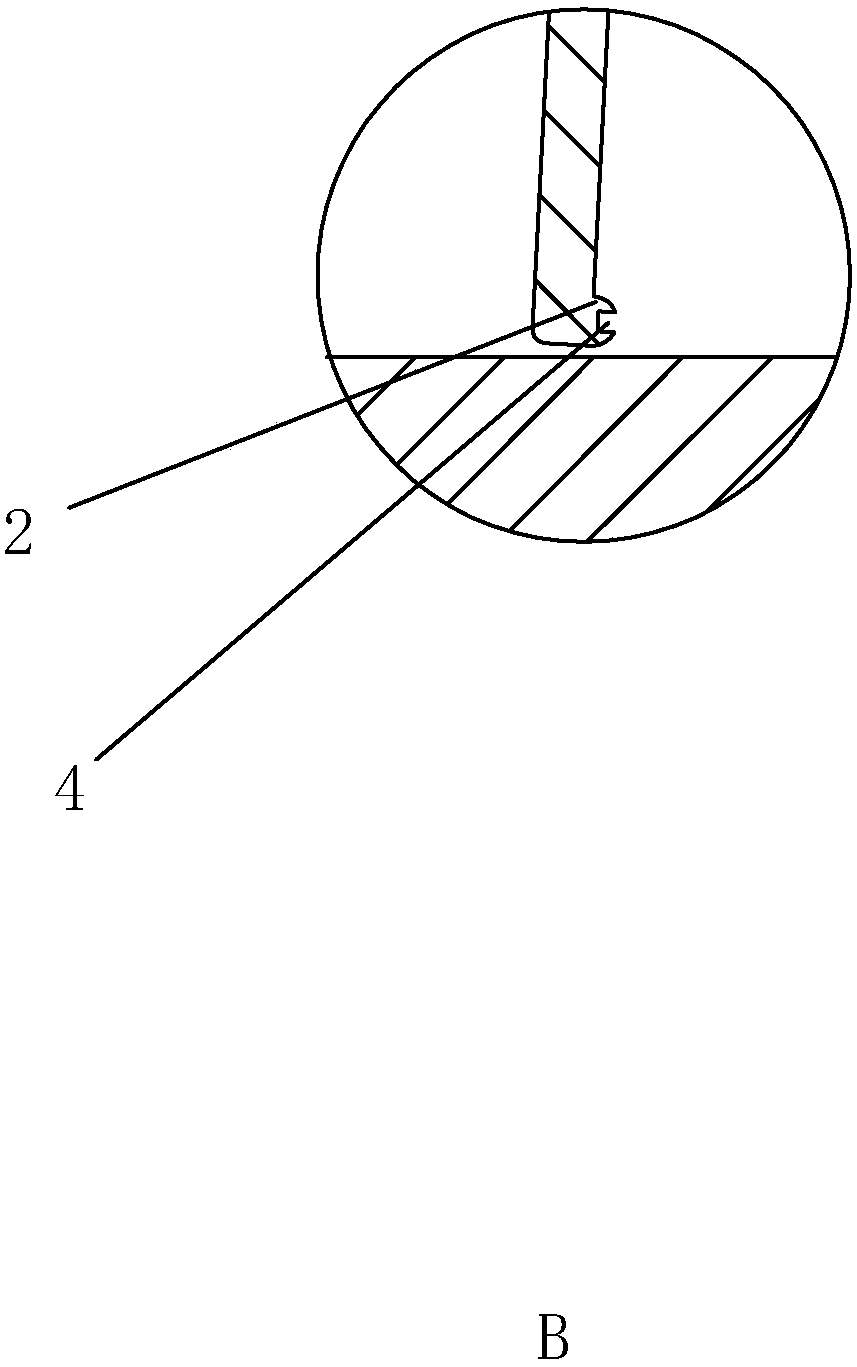

[0035] refer to Figure 1 to Figure 4, the upper side of each louver 7 is provided with a concave groove 3, the concave groove 3 is formed inwardly from the outer surface of the louver 7, and the lower side is provided with a raised strip 2, and the raised strip 2 is formed from the inner...

Embodiment 2

[0040] Embodiment 2: A kind of tuyere structure, refer to Figure 6 The difference from Embodiment 1 is that a rotation button 12 for driving one of the rotating shafts 6 to rotate itself is provided on the side wall of the frame body 1, and it works instead of the driving part 8. The staff drives the rotating shaft 6 to rotate by rotating the rotating button 12. The rotating shaft 6 drives other rotating shafts 6 to rotate synchronously through the transmission belt 9, thereby driving all the louver blades 7 to automatically rotate. The rotation of the louver blades 7 is controlled manually, and the failure rate is low and safe and stable.

Embodiment 3

[0041] Embodiment 3: A manufacturing method applied to the manufacture of the tuyere structure in Embodiment 1 and Embodiment 2 above. The frame body 1 is welded end-to-end by four profiles. Before welding, each profile is cut by a laser cutting process. Cut from the end to the end, remove the waste, and then connect the four profiles end to end, and weld them together by welding to form a rectangular parallelepiped frame 1. The end of the profile cut by the laser cutting process is relatively flat, without many burrs , when performing end-to-end welding with any two of the other three, the gap generated at the welding place is smaller, so that the contact area between the two profiles is larger during welding, and the welding effect achieved is more firm and stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com