Mowing machine

A lawn mower and main body technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as low cutting efficiency, and achieve the effects of simple structure, guaranteed efficiency, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

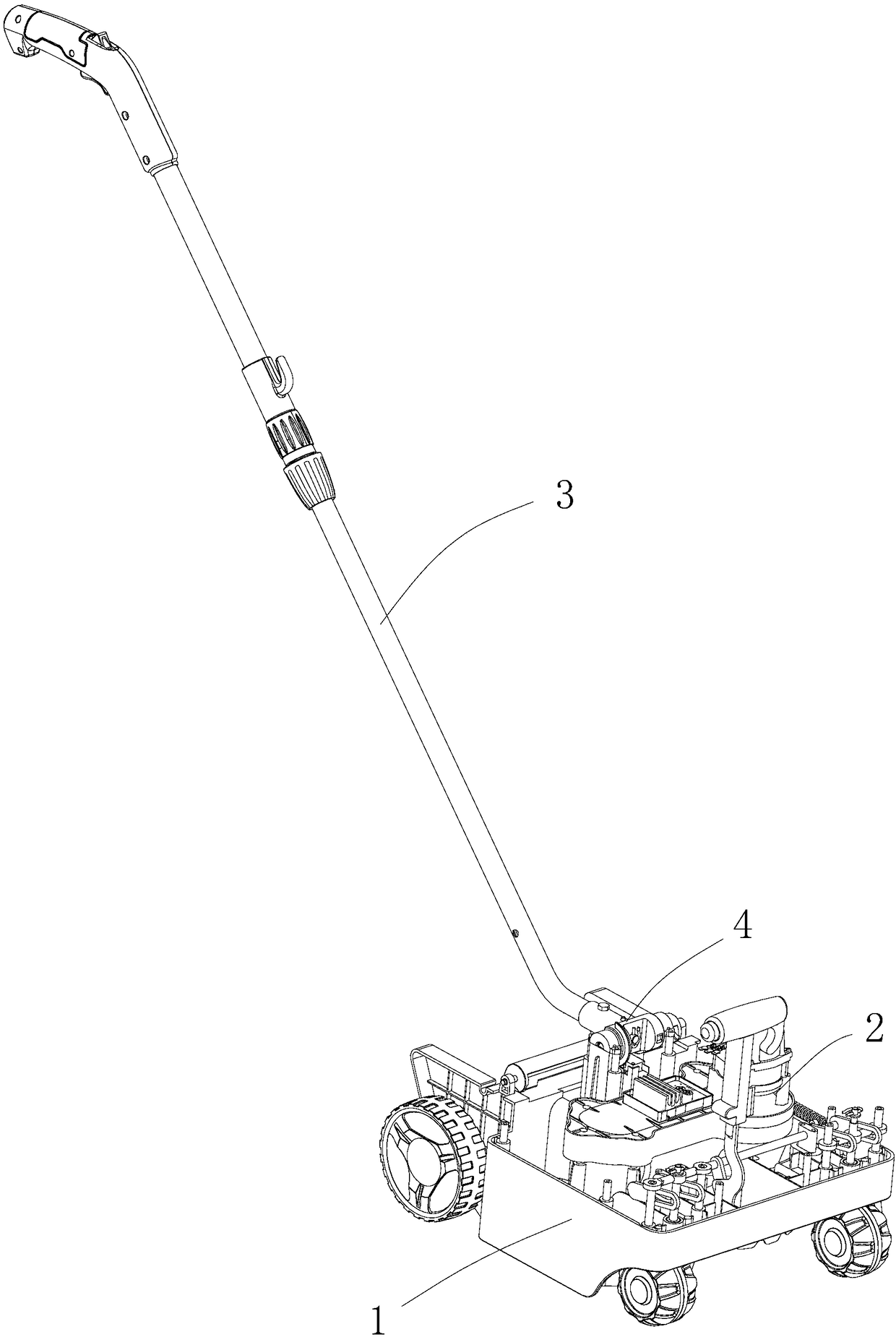

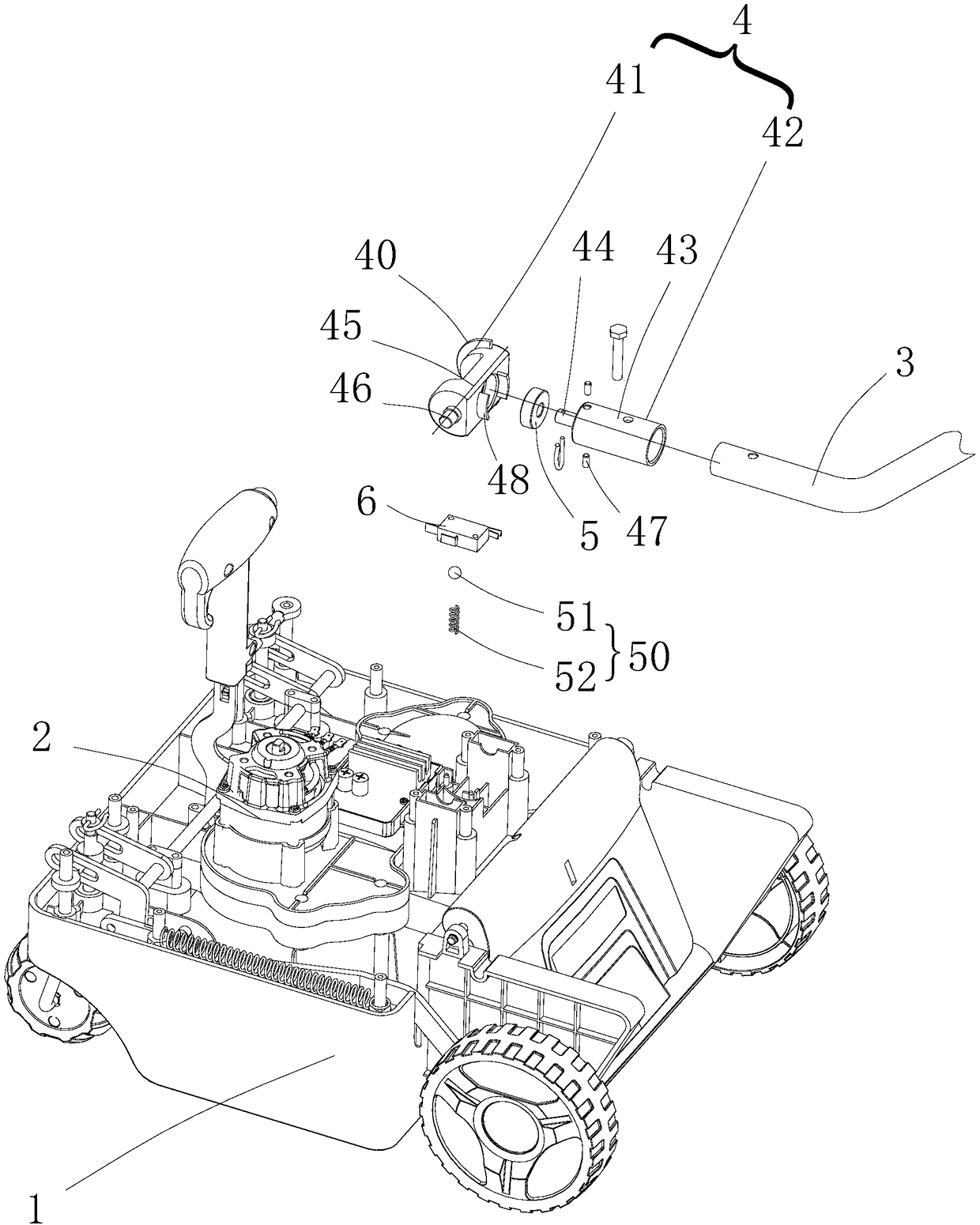

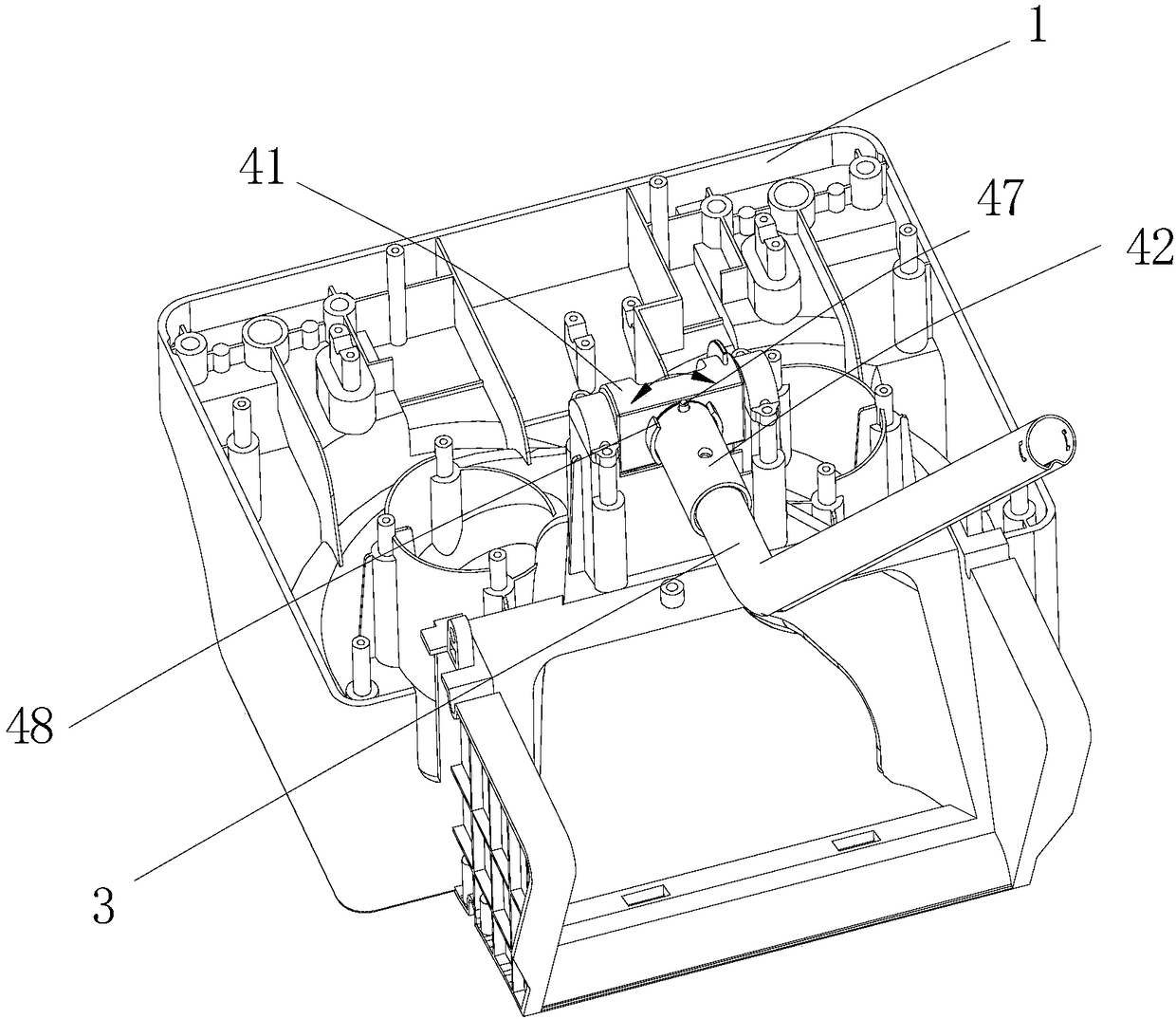

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a lawn mower includes a main body 1, a motor 2 arranged on the main body 1, and a handle mechanism 3 arranged on the main body 1, the handle mechanism 3 includes a movable joint 4, and the handle mechanism 3 is moved through The joint 4 is installed on the main body 1, and the handle mechanism 3 can rotate back and forth and left and right relative to the main body 1 along the cutting forward direction through the movable joint 4, and the handle mechanism 3 can rotate forward and backward relative to the main body 1 through the movable joint 4. Rotate left and right, so that the operator can choose the appropriate angle of the handle mechanism 3 relative to the main body 1 according to the obstacle, shorten the operator's walking distance, and do not need to walk around the obstacle to complete the cutting, which improves the cutting efficiency, and The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com