Engine braking method and device for modulating engine braking power

An engine braking and power technology, applied in the direction of engine control, engine components, combustion engine, etc., can solve problems such as adjusting engine braking power, and achieve the effect of flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

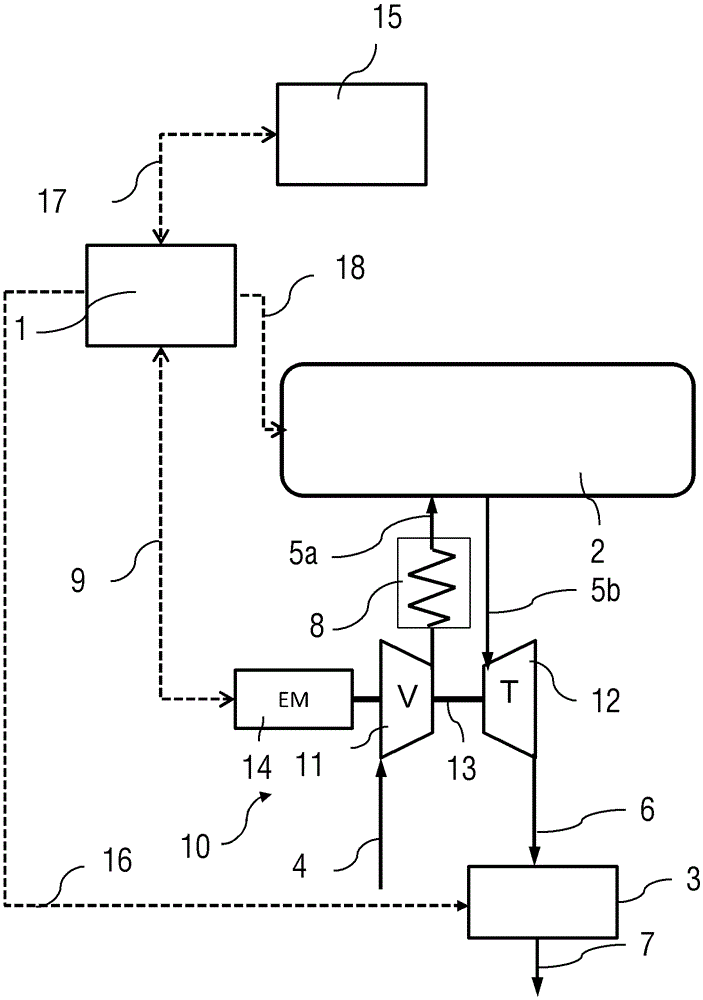

[0048] figure 1 An engine braking device according to an embodiment of the present invention is shown in block diagram form. The engine braking device comprises a supercharged internal combustion engine 2 of a commercial vehicle and an electric motor-assisted exhaust-gas turbocharger 10 associated therewith, also referred to hereinafter as ETC 10 . The motor-assisted exhaust-gas turbocharger 10 comprises a turbine 12 which is driven by exhaust gas from the internal combustion engine 2 , the exhaust gas being fed to the turbine 12 via the exhaust line 5 b. Thereafter, the exhaust-gas mixture flows via the turbine outlet through the exhaust line 6 , in which the engine brake disk 3 known per se is arranged, the exhaust-gas mixture flows via a further exhaust line 7 to the exhaust port. The turbine 12 is connected to the compressor 11 by a shaft 13 . Fresh air is fed to the compressor 11 via the compressor inlet 4 . The compressor 11 compresses charge air to feed the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com