Steel plate and concrete composite beam and slab structure system

A technology of steel plate concrete and laminated beams, which is applied to floor slabs, building components, building structures, etc., can solve problems such as small spans, limited seismic use, and large section heights, so as to increase floor net heights, reduce construction costs, Improve the effect of using space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] Step 1: According to the design requirements, the concrete corbel 15 is constructed on the wall column 14, and the construction joint is reserved, and the construction joint is the same as the top elevation of the prefabricated beam.

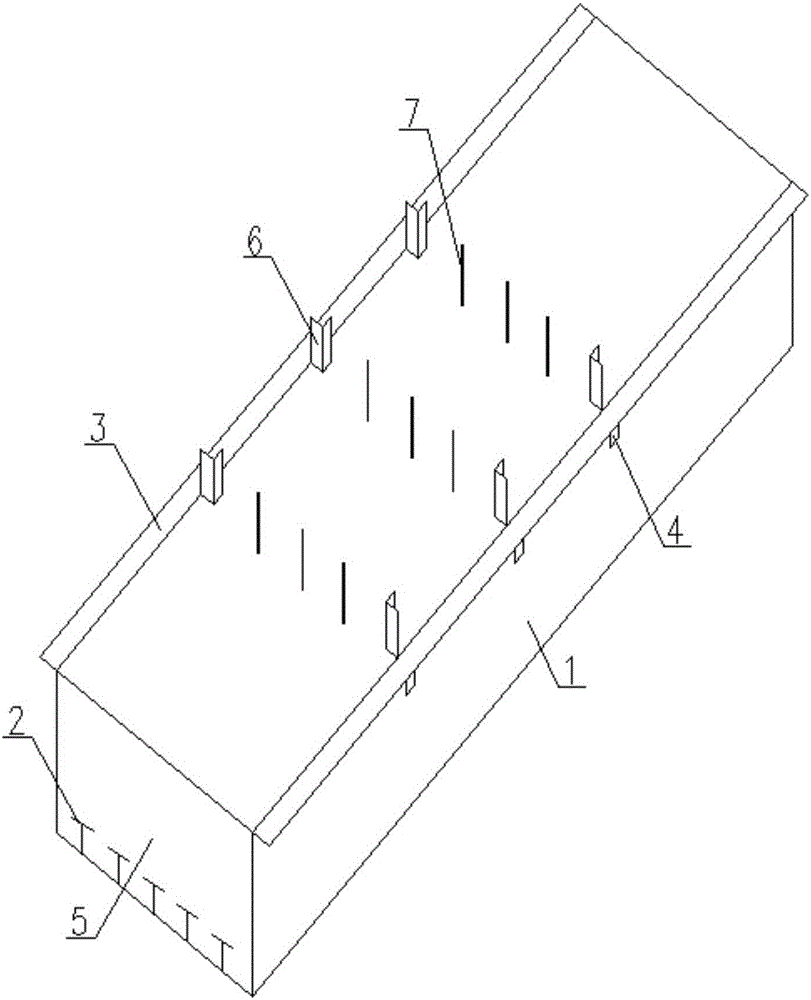

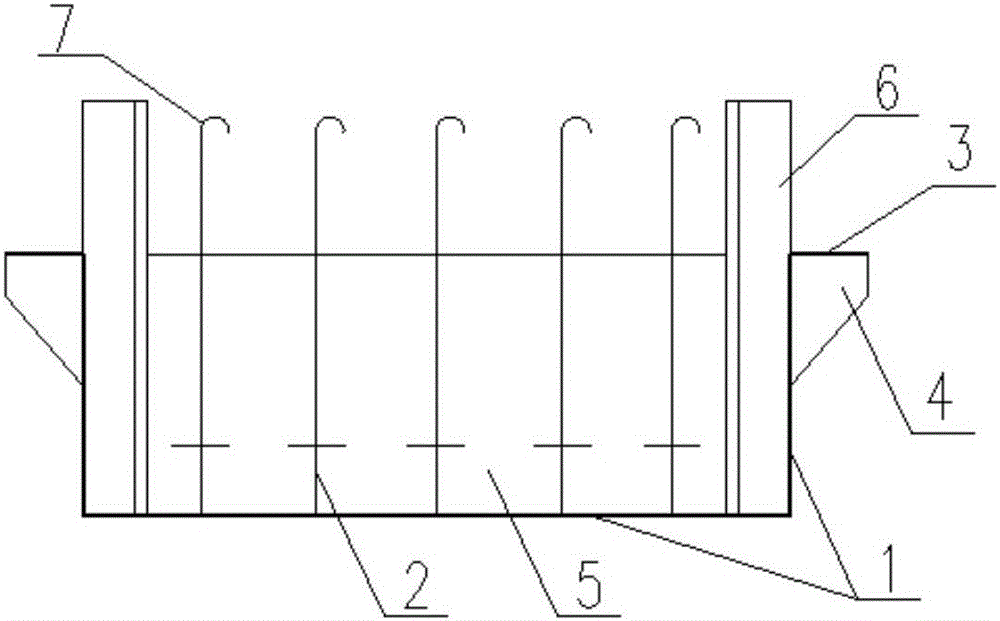

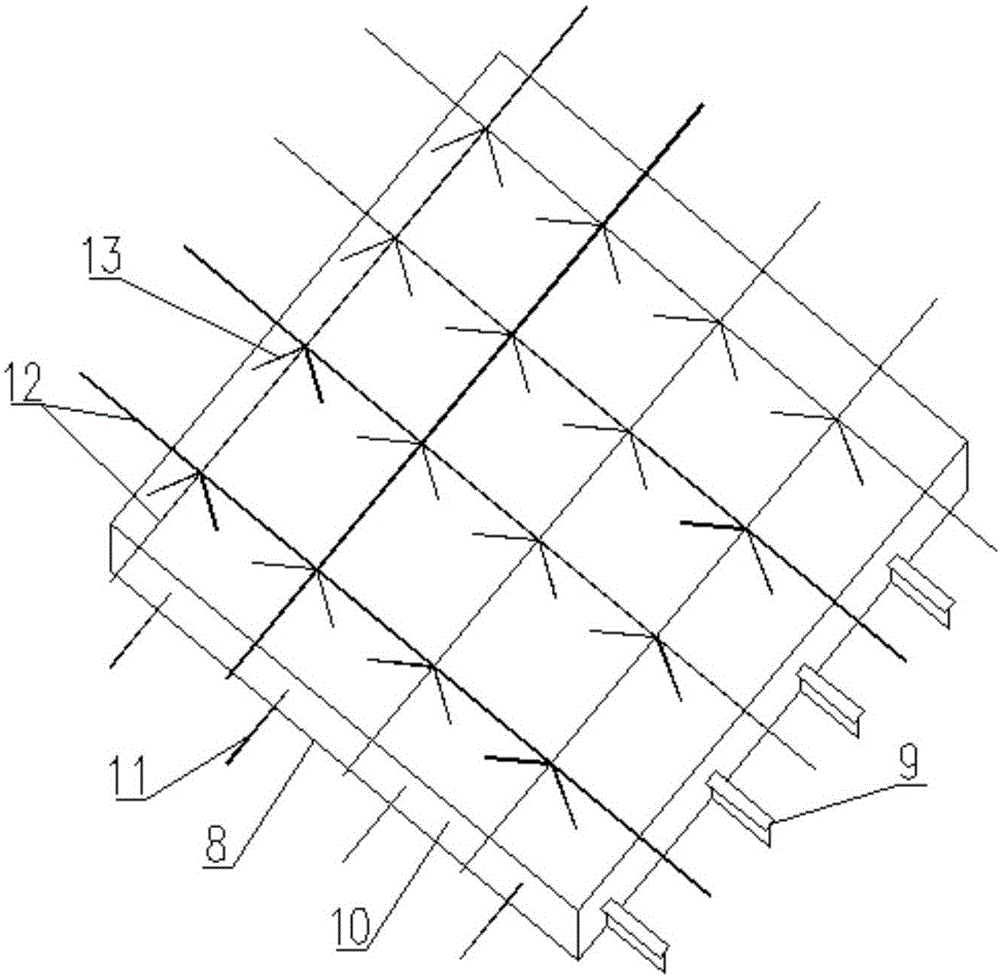

[0032] Step 2: The factory manufactures steel plate concrete prefabricated beams, and completes the installation of steel plates at the bottom and both sides of the beam 1, T-shaped steel at the bottom of the beam 2, angle steel at the side of the beam 6 and pick ears 3, longitudinal steel bars at the top of the beam 19, and tie bars at the middle of the beam 7. material; open a hole at the top of the beam side angle steel 6, weld the beam side angle steel 6 and the beam side steel plate 1, weld the pick ear 3 and the stiffener 4 at the top of the beam side steel plate; weld the tie bar 7 at the top 2 of the T-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com