breakout wall

A wave wall and wall technology, used in breakwaters, water conservancy projects, marine engineering and other directions, can solve the problems of unsustainable aesthetic effects, slow construction speed, and increased flood resistance pressure, etc., to increase ecological and aesthetic effects, save materials, The effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

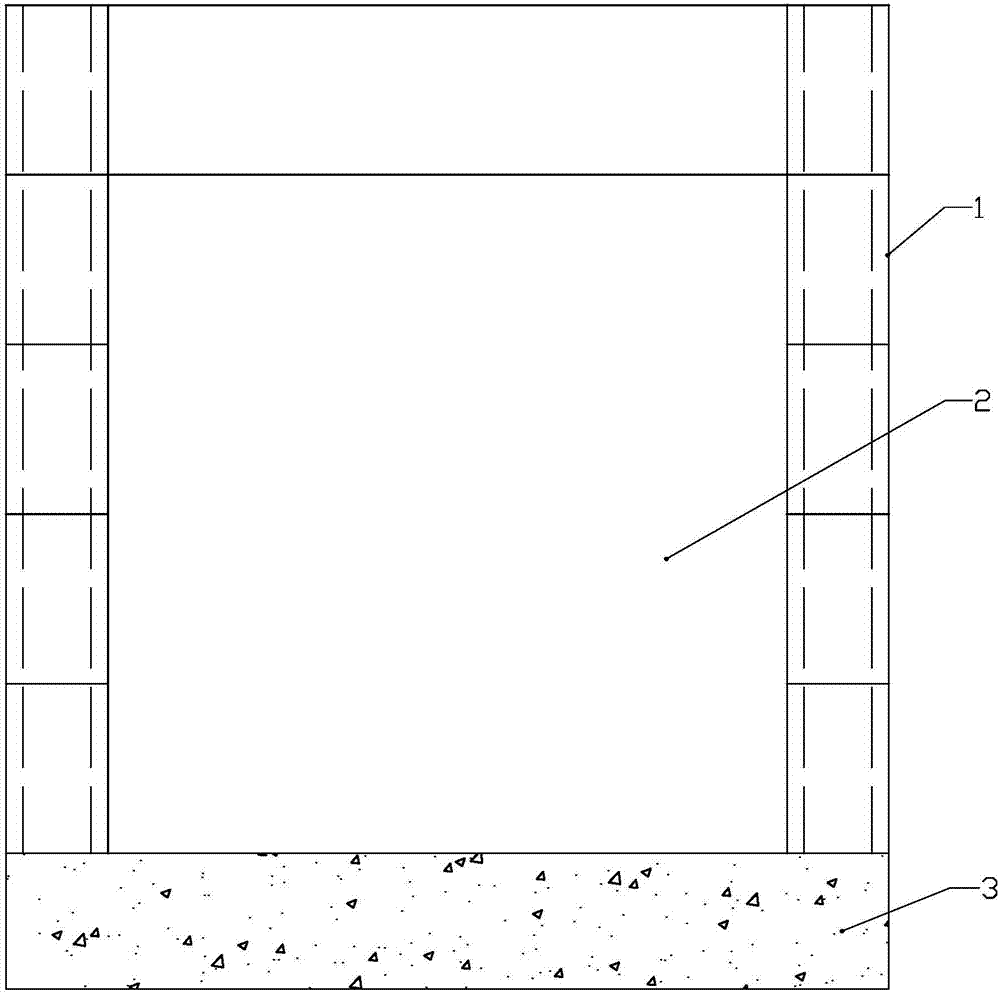

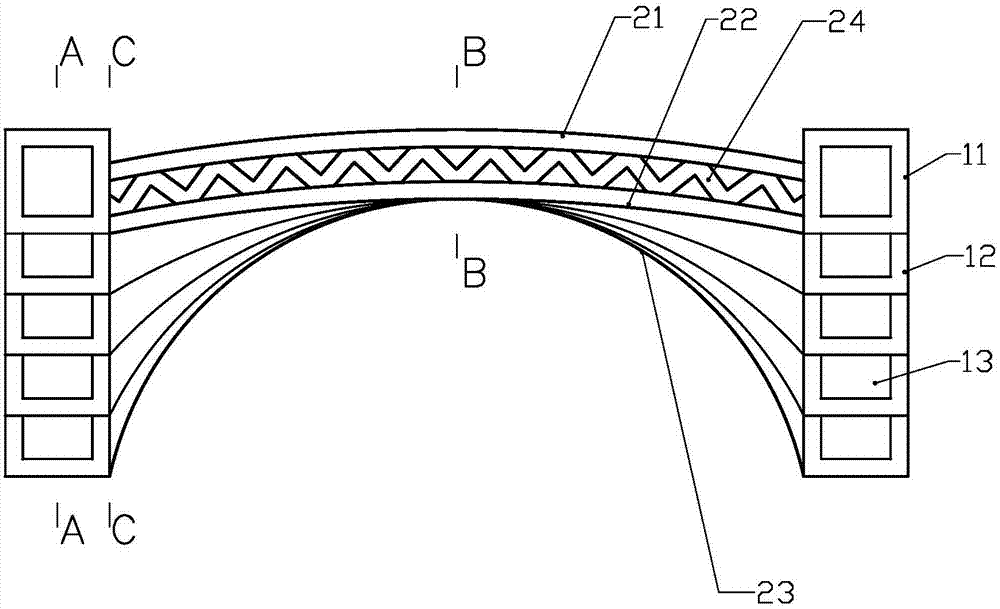

[0018] Refer to the attached figure 1 To attach Figure 5 The wave wall of the present invention will be described in detail below.

[0019] The structure of the anti-wave wall of the present invention includes at least two gravity piers 1 and a wall 2 connecting two adjacent gravity piers, the wall 2 is an arc-shaped wall, and the wall 2 includes an outer wall Body 21, middle wall body 22 and inner wall body 23, described middle wall body 22 is arranged between outer layer body of wall body 21 and inner layer body of wall body 23, described outer layer body of wall body 21 and middle layer body of wall body 22 from The shape is consistent from top to bottom, and there is a corrugated support body 24 between the outer wall 21 and the middle wall 22. The inner wall 23 is an inner concave whose arc surface diameter gradually decreases from top to bottom. The arc-shaped body weakens the impact of waves on the wall; each of the gravity piers 1 includes a rear pier body 11 and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com