A kind of manufacturing method of multifunctional flame-retardant polyester fabric

A flame-retardant polyester and manufacturing method technology, applied in the field of functional textile materials, can solve the problems of single function, easy perforation and droplet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Pad the polyester fabric dyed with warning fluorescent high temperature at 100-130°C in the first step of padding liquid, then pre-bake the polyester fabric at 110°C-130°C for 3 minutes, and then bake it at 160°C-180°C for 3 minutes , After the fabric is shaped and cooled, the reverse side of the fabric is subjected to high temperature oil surface calendering at 140°C-160°C for 3 times, and the weight of the polyester fabric increases by 0.8% after the treatment is completed.

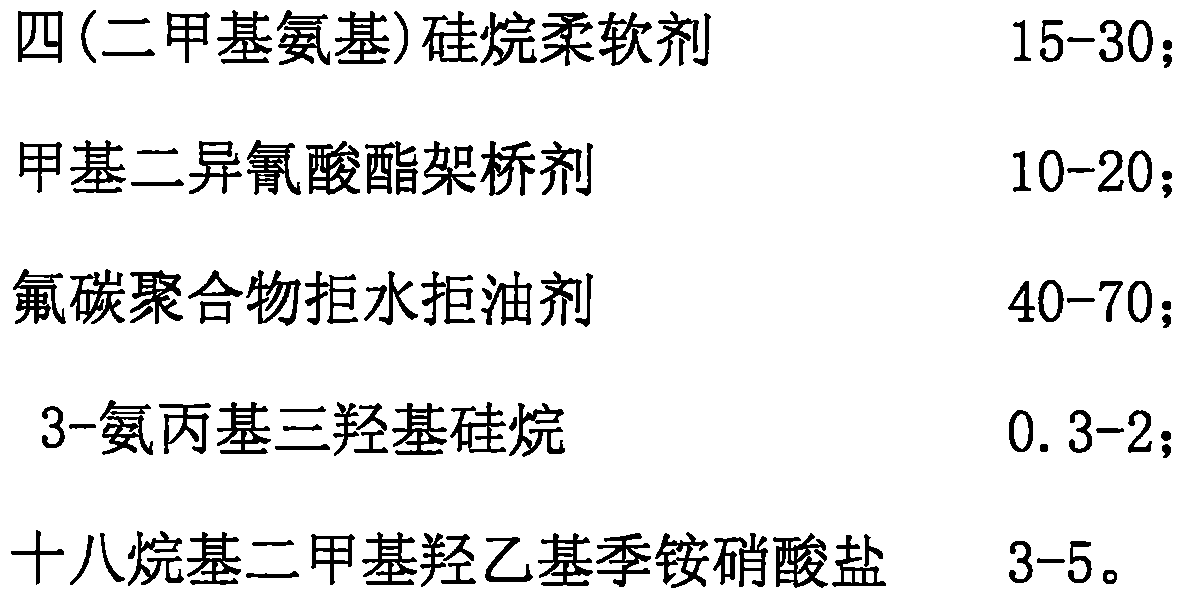

[0023] Wherein said first step padding solution is calculated and composed as follows in parts by mass:

[0024]

[0025] Then, on the calendered side of the polyester fabric, apply the second-step primer liquid, and after forming a uniform adhesive film on the surface of the polyester fabric, place the polyester fabric at 140-160°C for baking for 5 minutes , After the treatment is completed, the polyester fabric weight increases by 6%.

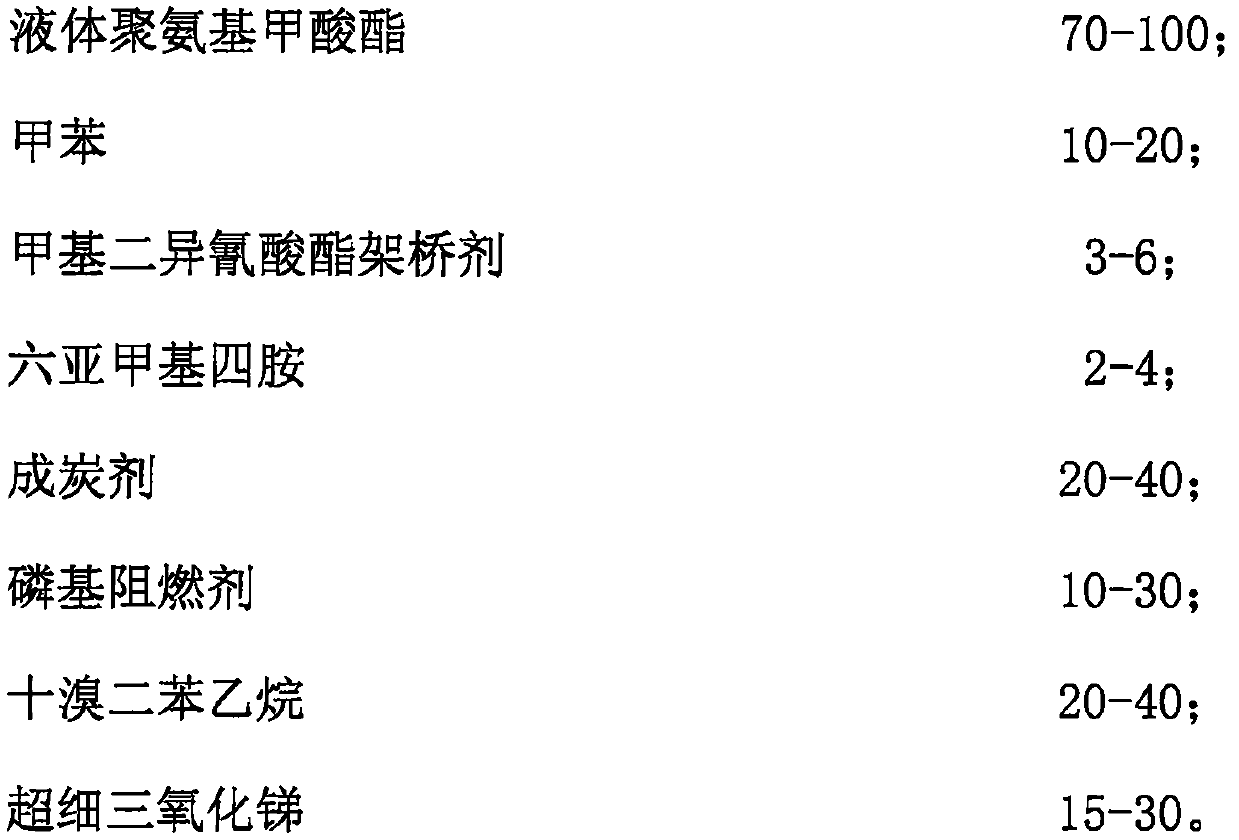

[0026] Wherein said second step primer slurry is count...

Embodiment 2

[0036] Pad the polyester fabric dyed with warning fluorescent high temperature at 100-130°C in the first padding liquid, then pre-dry the polyester fabric at 110°C-120°C for 1.5 minutes, and then bake it at 160°C-180°C for 1.5 minutes , After the fabric is shaped and cooled, then the reverse side of the fabric is subjected to high temperature oil surface calendering at 100°C-160°C for 2 times; after the treatment is completed, the weight of the polyester fabric increases by 0.5%.

[0037] Wherein said first step padding solution is calculated and composed as follows in parts by mass:

[0038]

[0039] Then, on the calendered side of the polyester fabric, apply the second-step primer liquid, and after forming a uniform adhesive film on the surface of the polyester fabric, place the polyester fabric at 140-150°C for baking, and the baking time needs 3 Minutes; 4% increase in weight of polyester fabric after gluing.

[0040] Wherein said second step primer slurry is counted a...

Embodiment 3

[0050] Pad the polyester fabric dyed with warning fluorescent high temperature at 120-130°C in the first step of padding liquid, then pre-dry the polyester fabric at 110°C-120°C for 2 minutes, and then bake it at 160°C-180°C for 2 minutes , After the fabric is shaped and cooled, the reverse side of the fabric is subjected to high temperature oil surface calendering at 140°C-150°C for 3 times; after the treatment is completed, the weight of the polyester fabric increases by 1%.

[0051] Wherein said first step padding solution is calculated and composed as follows in parts by mass:

[0052]

[0053] Then, on the calendered side of the polyester fabric, apply the second-step primer liquid, and after forming a uniform adhesive film on the surface of the polyester fabric, place the polyester fabric at 130-140°C for baking, and the baking time needs 3 Minutes; 5% increase in weight of polyester fabric after gluing.

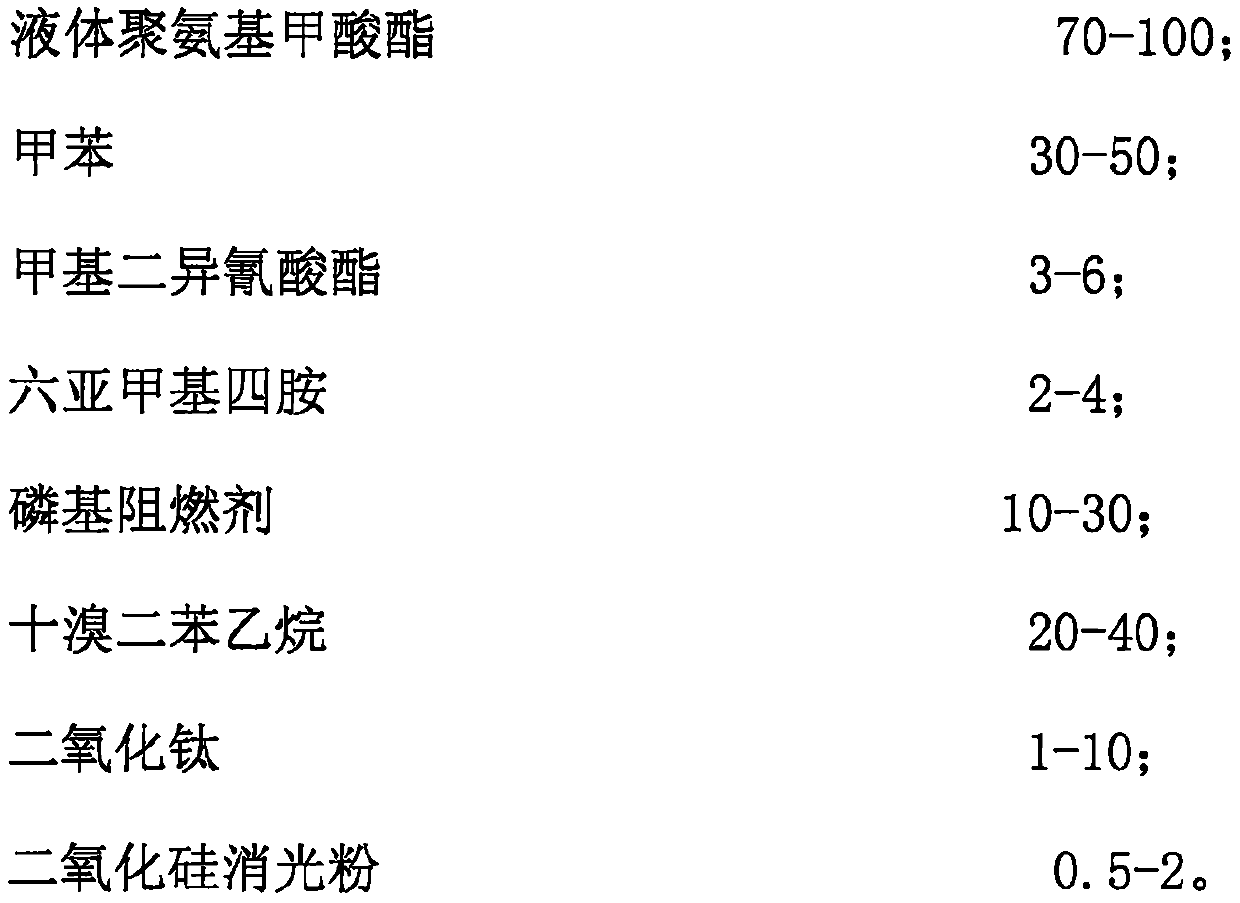

[0054]Wherein said second step primer slurry is counted and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com