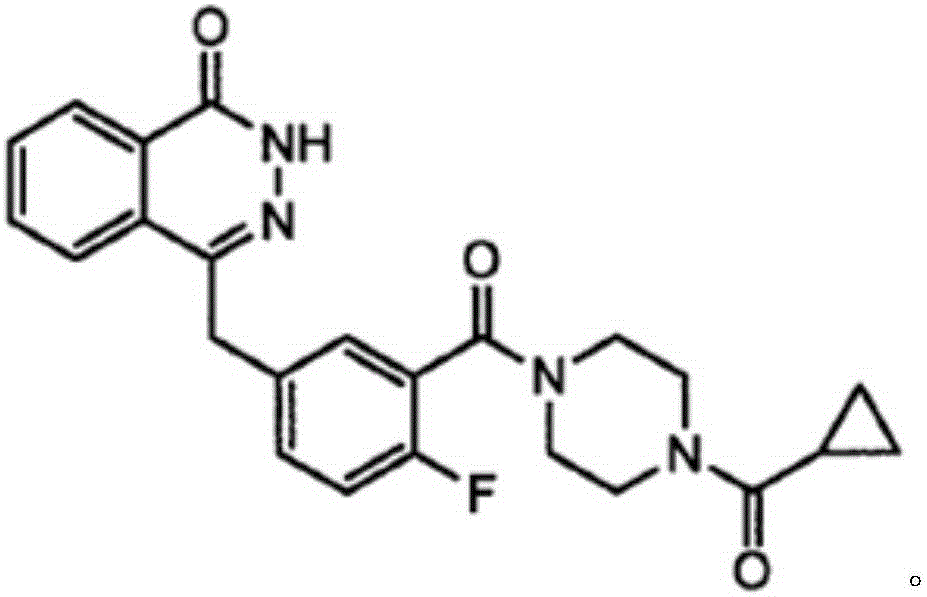

Preparing method for Olaparib

A compound and catalyst technology, applied in the field of preparation of olaparib, can solve the problems of difficult process control, many by-products, long routes, etc., and achieve mild and easy-to-control reaction conditions, high yield, simple operation and post-treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

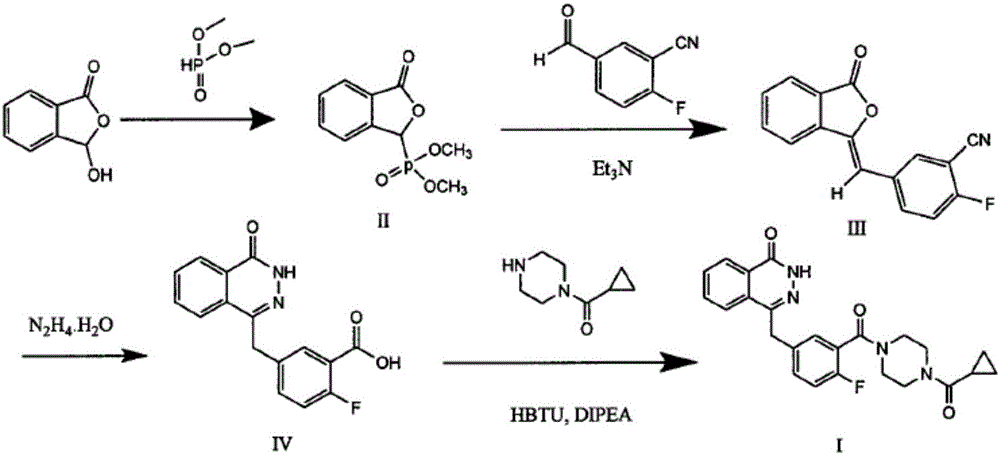

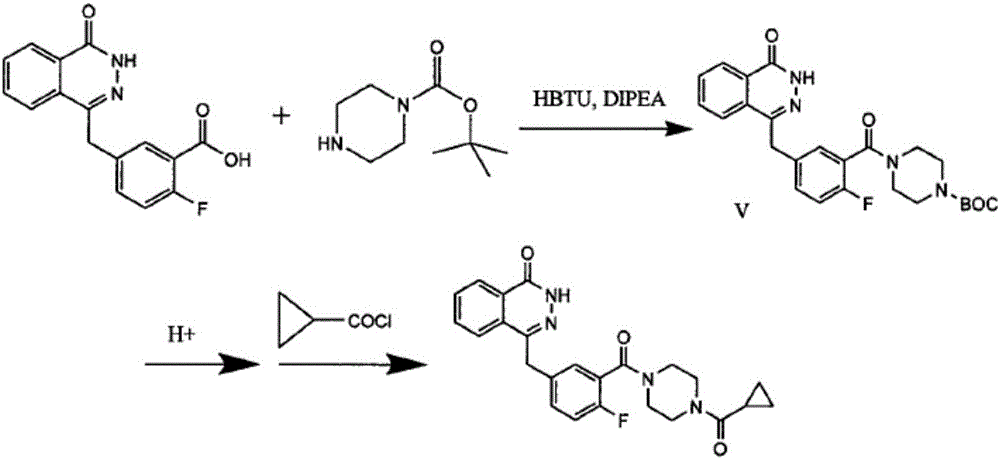

Method used

Image

Examples

Embodiment 1-1

[0037] Embodiment 1-1: Synthesis of Compound 3

[0038] Magnesium (2.4 g, 0.1 mol), triethylamine (59 g, 1 mol) and compound 2 (359.7 g, 3 mol) were added to 5 L of tetrahydrofuran. Compound 1 (247 g, 1 mol) was added, heated to 60° C., and stirred for 2 h. After the reaction was completed, tetrahydrofuran was distilled off under reduced pressure. Then use 0.1M hydrochloric acid solution to acidify the solution to pH 1, extract with ether, combine the organic phase, and wash the organic phase with anhydrous MgSO 4 After drying, suction filtration and vacuum drying, compound 3 (197 g, 0.93 mol) was obtained with a yield of 93% and a purity of 99.5% by HPLC.

Embodiment 1-2

[0039] Embodiment 1-2: the synthesis of compound 3

[0040]Magnesium (4.8 g, 0.2 mol), triethylamine (82.6 g, 1.4 mol) and compound 2 (155.9 g, 1.3 mol) were added to 5 L of acetonitrile. Add compound 1 (247g, 1mol), heat to 65°C, and stir for 2h. After the reaction is complete, tetrahydrofuran is distilled off under reduced pressure. Then use 0.1M hydrochloric acid solution to acidify the solution to pH 1, extract with ether, combine the organic phase, and wash the organic phase with anhydrous MgSO 4 After drying, suction filtration and vacuum drying, compound 3 (201 g, 0.95 mol) was obtained with a yield of 95% and a purity of 99.8% by HPLC.

Embodiment 1-3

[0041] Embodiment 1-3: the synthesis of compound 3

[0042] Magnesium (7.2 g, 0.3 mol), triethylamine (118 g, 2 mol) and compound 2 (120 g, 1 mol) were added to 5 L of tetrahydrofuran. Compound 1 (247 g, 1 mol) was added, heated to 70°C, and stirred for 2 h. After the reaction was completed, tetrahydrofuran was distilled off under reduced pressure. Then use 0.1M hydrochloric acid solution to acidify the solution to pH 1, extract with ether, combine the organic phase, and wash the organic phase with anhydrous MgSO 4 After drying, suction filtration and vacuum drying, compound 3 (195 g, 0.92 mol) was obtained with a yield of 92% and a purity of 99.5% by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com