Method for directly preparing granular water-soluble fertilizer by using urea production intermediate

A granular urea technology, which is applied in urea compound fertilizers, inorganic fertilizers, nitrate fertilizers, etc., can solve the problems of easy caking of powdered water-soluble fertilizers, difficulty in fertilization operations, waste of energy, etc., to shorten product cooling time and facilitate Fertilization operation, effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the preparation of granular macroelement water-soluble fertilizer (middle element Ca+Mg type):

[0022] Add 64.5kg of tripotassium phosphate, 40.3kg of potassium dihydrogen phosphate, 40.3kg of potassium sulfate, 24.2kg of calcium nitrate, and 24.2kg of magnesium sulfate into 806.5kg of urea solution (temperature above 132.7°C) in batches to maintain the reaction temperature Above 132.7°C, stir evenly to make a slurry, then spray the slurry through a granulation nozzle, and use the urea tower to cool and granulate with natural air to obtain granular macroelement water-soluble fertilizer (medium element Ca+Mg type). The performance index is shown in Table 1, and the obtained product complies with the national standard.

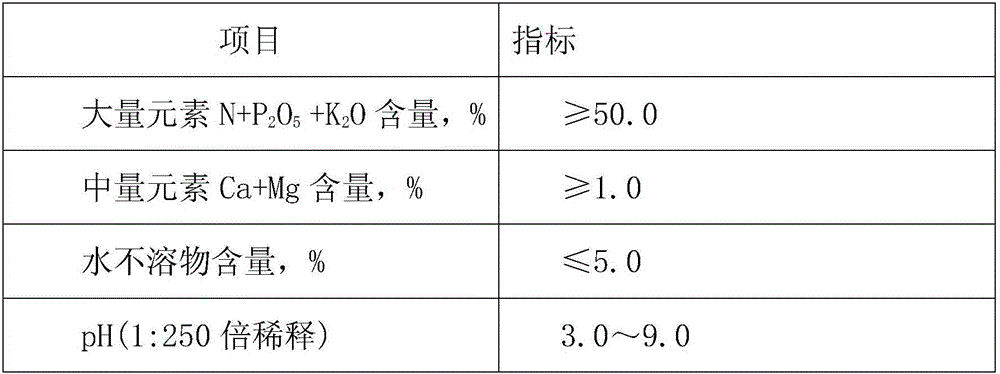

[0023] Table 1 Product quality index of granular macroelement water-soluble fertilizer (moderate element Ca+Mg type)

[0024]

[0025]

Embodiment 2

[0026] Embodiment 2: the preparation of granular macroelement water-soluble fertilizer (middle element Ca type)

[0027] Add 78.4 kg of dipotassium hydrogen phosphate, 47.1 kg of potassium dihydrogen phosphate, 43.1 kg of potassium nitrate, and 47.1 kg of calcium nitrate into 784.3 kg of urea solution (temperature above 132.7°C) in batches, and maintain the reaction temperature above 132.7°C , stir evenly to make a slurry, then spray the slurry through a granulation nozzle, and use the urea tower to cool and granulate with natural air to obtain a granular macroelement water-soluble fertilizer (moderate element Ca type). The performance indicators are shown in Table 2. The obtained product conforms to the national standard.

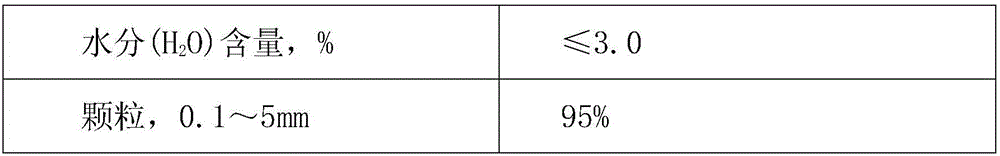

[0028] Table 2 Product quality index of granular macroelement water-soluble fertilizer (moderate element Ca type)

[0029] project

Embodiment 3

[0030] Embodiment 3: the preparation of granular macroelement water-soluble fertilizer (middle element Mg type)

[0031] Add 200.0kg of tripotassium phosphate, 50.0kg of potassium dihydrogen phosphate, 100.0kg of potassium sulfate, 90.0kg of potassium nitrate, and 60.0kg of magnesium sulfate into 500.0kg of urea solution (temperature above 132.7°C) in batches to maintain the reaction temperature Above 132.7°C, stir evenly to make a slurry, then spray the slurry through a granulation nozzle, and use the urea tower for natural air cooling to granulate to obtain a granular macronutrient water-soluble fertilizer (middle element Mg type), performance indicators As shown in Table 3, the obtained product complies with the national standard.

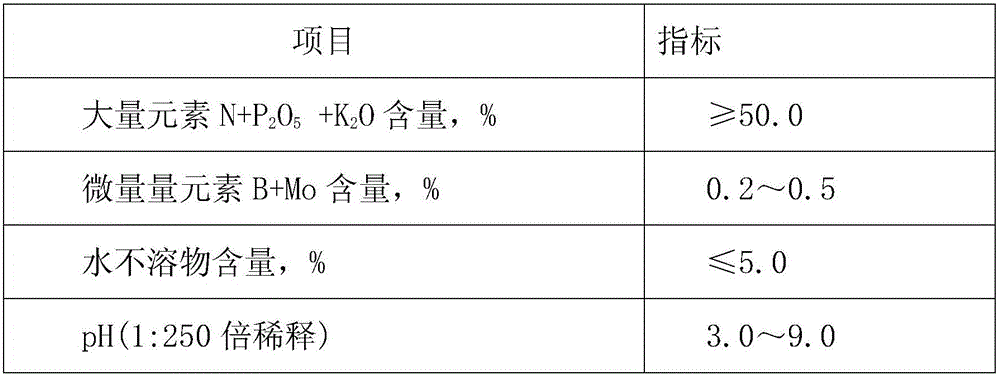

[0032] Table 3 Product quality index of granular macroelement water-soluble fertilizer (middle element Mg type)

[0033] project

[0034] 6 kinds of trace elements Cu, Fe, Mn, Zn, B, Mo and macroelements N+P in granular macroelement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com