Production method for rotor of hub driving motor with built-in tangential and radial permanent magnet steels

A technology of wheel hub drive and production method, applied in the manufacture of motor generators, electromechanical devices, manufacture of stator/rotor bodies, etc., can solve the problems of descending, irreversible demagnetization, reduction of drive motor efficiency, etc., to achieve high efficiency, compact structure, magnetic field strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

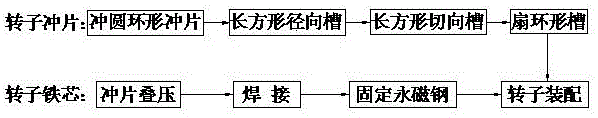

[0008] The present invention will be further described below in conjunction with accompanying drawing:

[0009] The production method of the built-in tangential and radial permanent magnet steel rotors of the hub drive motor is characterized in that: punching and cutting the ring-shaped rotor punching sheet, and evenly distributed on the rotor punching sheet are evenly distributed rectangular shapes and sizes that run through the thickness of the rotor punching sheet Radial groove, the inner side of the rectangular radial groove is a convex arc, the arch height of the convex arc is 1mm, and there is a 1.5mm disconnected part between the bottom end of the rectangular radial groove and the inner circle of the rotor punch. In the middle of the inner ends of two adjacent rectangular radial grooves, there is a rectangular tangential groove that runs through the thickness of the rotor punch. The rectangular radial groove and the rectangular tangential groove are not connected. Both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com