1kv aluminum-core overhead cable

An overhead cable and aluminum core technology, which is applied in the field of power cables, can solve the problems of poor resistance to external wind and rain, failure to reach the tension of long-distance erected cables, and restrictions on overhead spans, so as to improve performance advantages and reduce Skin effect, low-density filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

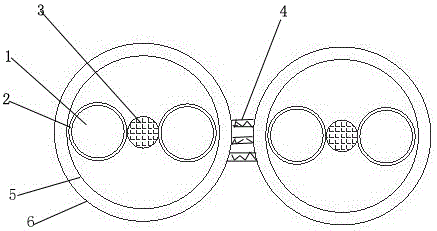

[0016] Such as figure 1 As shown, a 1kv aluminum-core overhead cable according to the present invention includes two parallel cables with the same vertical structure, and the two cables are connected by a plurality of connecting ribs 4; the cables include a cable core , the outer sheath 5 extruded outside the cable core and the plastic cooling pipe 6 arranged outside the outer sheath, the plastic cooling pipe 6 is provided with cooling liquid, the heat transfer through the wall of the cooling pipe will be in the entire circumference of the cooling pipe The surroundings are balanced, and the effective heat transfer to the cooling liquid arranged in the cooling pipe is realized, so that the overall heat of the cable is reduced and the skin effect is reduced; the cable core is composed of a carbon fiber filament 3 and a parallel symmetrical carbon fiber It consists of two aluminum wires on both sides of the wire.

[0017] Wherein, the aluminum wire is composed of an aluminum con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com