Mid-infrared electro-optical modulator based on black phosphorus fluoride waveguide

An electro-optic modulator and fluoride technology, which is applied in the field of optical communication, can solve the problems that mid-infrared light cannot pass through, achieve the effect of flat mid-infrared spectrum transmission window, convenient manufacture, and favorable integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

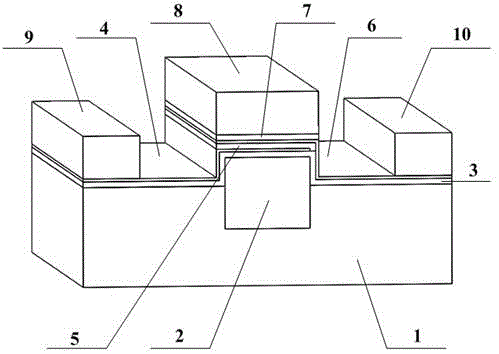

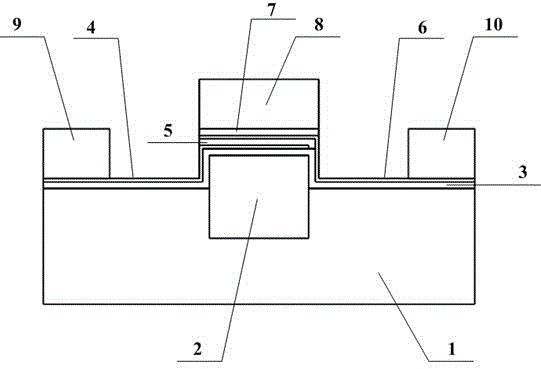

[0034] A mid-infrared electro-optic modulator based on black phosphorus fluoride waveguide, comprising a substrate layer 1, a groove is opened on the upper surface of the substrate layer 1, a first optical waveguide 2 is arranged in the groove, and the first optical waveguide 2 is arranged in the groove. On the upper surface of an optical waveguide 2, a first isolation dielectric layer 3, a first black phosphorus layer 4, a second isolation dielectric layer 5, a second black phosphorus layer 6, and a third isolation dielectric layer 7 are sequentially stacked from bottom to top. , the upper surface of the third isolation dielectric layer 7 is provided with a second optical waveguide 8, the first black phosphorus layer 4 extends from the left side of the first optical waveguide 2 and is connected to the first electrode 9, the second The black phosphorus layer 6 extends from the right side of the first optical waveguide 2 and is connected to the second electrode 10; the materials...

Embodiment 2

[0036] Based on the first embodiment, the fluoride glass is fluorozirconate glass or fluoroaluminate glass.

Embodiment 3

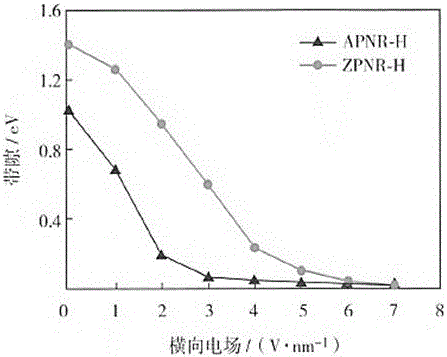

[0038] On the basis of Embodiment 1 or Embodiment 2, the materials of the first black phosphorus layer 4 and the second black phosphorus layer 6 are passivated black phosphorus nanobelts.

[0039] Preferably, the passivated black phosphorus nanobelts are hydrogen-saturated passivated black phosphorus nanobelts or fluorine-saturated passivated black phosphorus nanobelts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com