Liquid flow metering device

A metering device and liquid flow technology, which is applied in the direction of mass flow measuring device, measuring device, liquid/fluid solid measurement, etc., can solve the problems of increasing flowmeter connection links, large liquid storage, long drainage time, etc., to save Complicated labor and downtime waiting, fast and stable flow adjustment, accurate and reliable value transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

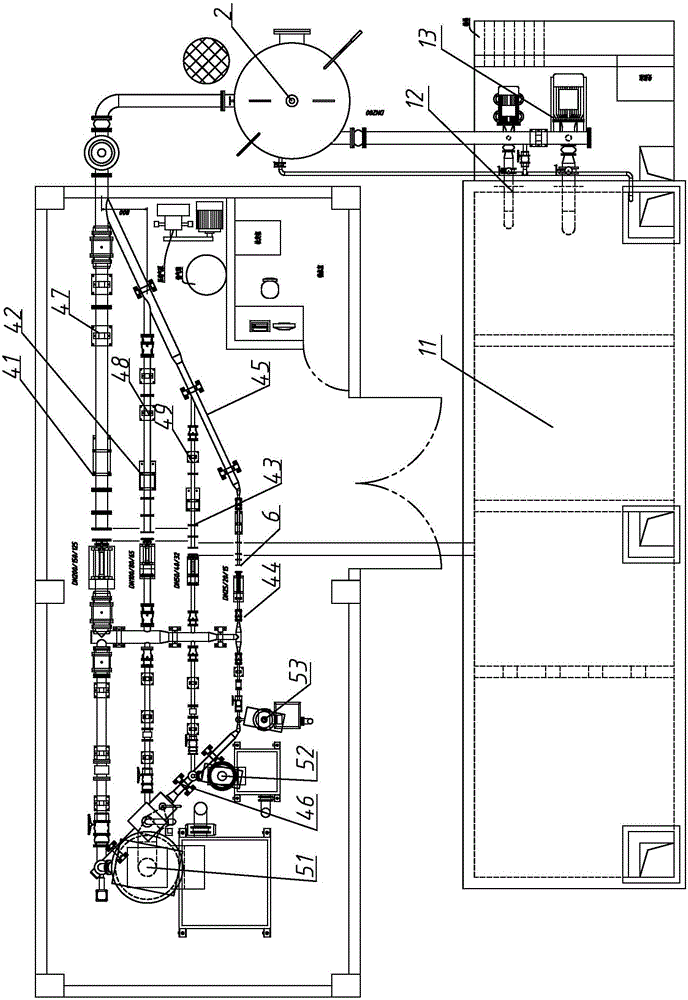

[0030] Such as figure 1The liquid flow metering device shown in includes a water storage circulation device 1, a surge tank 2, a standard flow meter 3, a flow regulating device 4 and a weighing device 5;

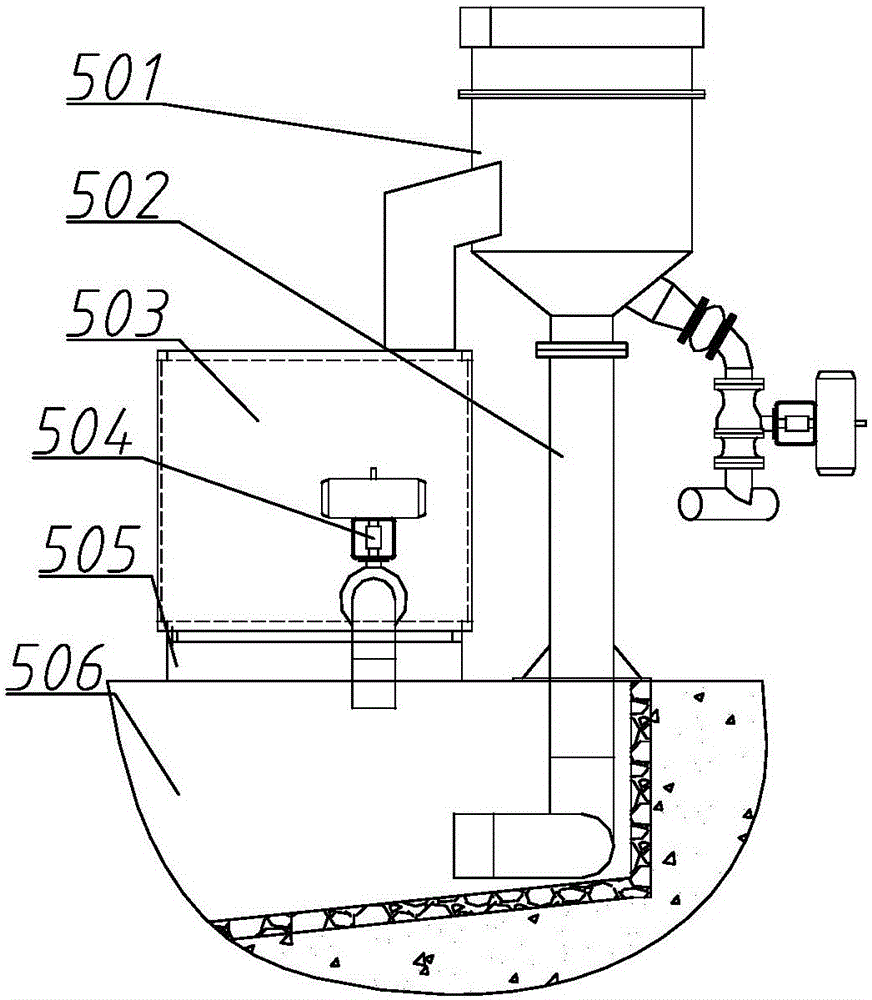

[0031] Water storage circulation device 1 comprises the storage tank 11 that is provided with storage tank water inlet pipe and storage tank outlet pipe; The water inlet is connected to the water inlet pipe of the water storage tank; the output port of the surge tank 2 is connected to the input port of the flow regulating device 4 through a pipeline provided with a filter;

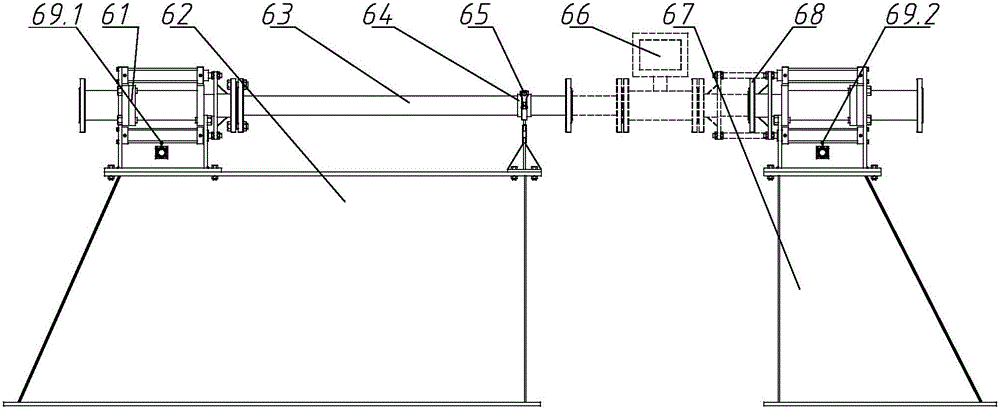

[0032] The flow regulator 4 comprises a first main line 41, a second main line 42, a third main line 43, a fourth main line 44, a first branch line 45, a second branch line 46; the first main line 41, the second main line Line 42, the third main line 43 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com