Titanium piston

A titanium metal and piston technology, applied in the field of engine parts manufacturing, can solve the problems of cumbersome manufacturing process, high manufacturing cost, low efficiency, etc., achieve the effect of complete process, reduce the level of processing equipment, and simplify the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

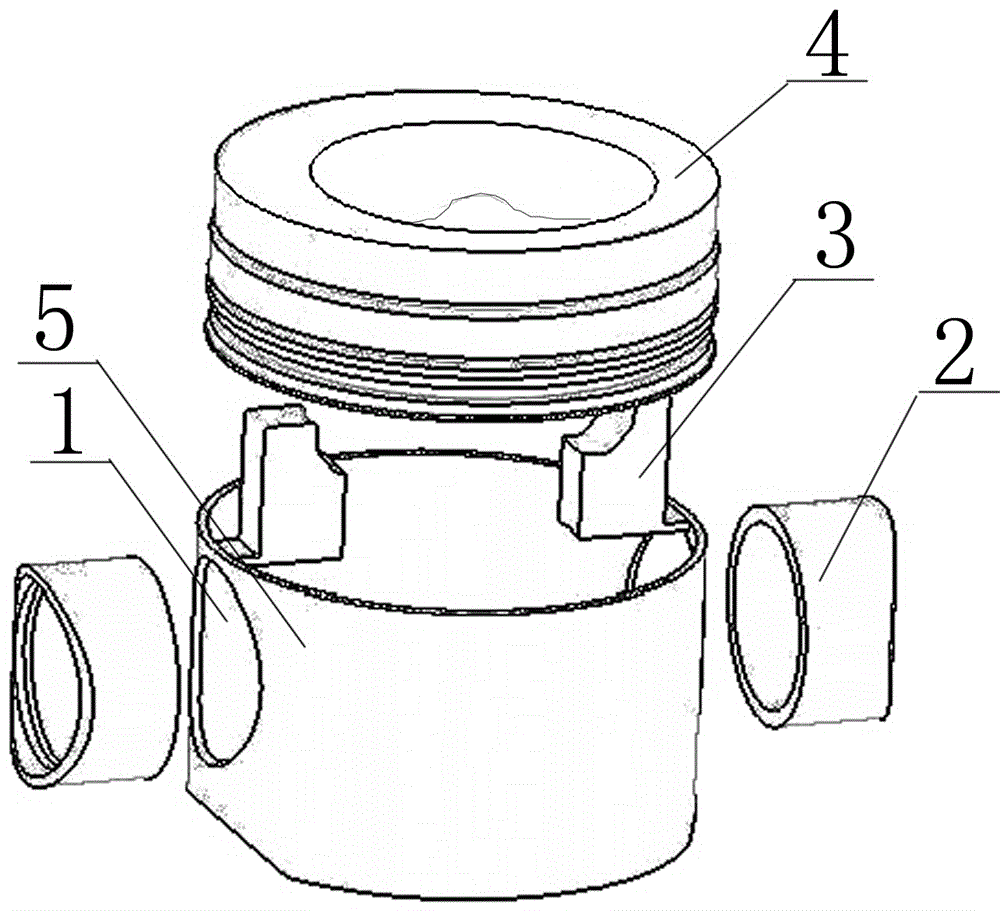

[0015] The following combination figure 1 , the content of the present invention will be described in detail through specific embodiments. The titanium metal piston includes a piston crown with a concave arc crater, a piston pin hole tube seat, a cylindrical piston skirt and a piston pin hole tube, and a pair of piston pin holes are symmetrically arranged on the piston skirt, and it is characterized in that: the titanium metal piston It is welded by the piston top, piston pin hole tube seat, piston skirt and reinforcing ribs. The piston top is welded to one end of the piston skirt, and a pair of piston pin hole tubes are relatively welded in the piston skirt. The piston pin hole tube is supported by the piston pin hole tube. Welded on the inside of the piston pin hole.

[0016] The manufacturing method of this titanium metal piston comprises the following steps:

[0017] Step 1) Cutting and stretching titanium metal rods into piston top blanks, using isothermal die forging p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com