Processing method for comprehensive mechanical coal mining working surface to quickly pass karst collapse column

The technology of karst collapse column and fully mechanized mining face is applied in the field of comprehensive mechanized coal mining working face to quickly pass through karst collapse column, and comprehensive mechanized coal mining working face to deal with special geological bodies, which can solve the problems of low efficiency, high consumption and equipment damage, etc. achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

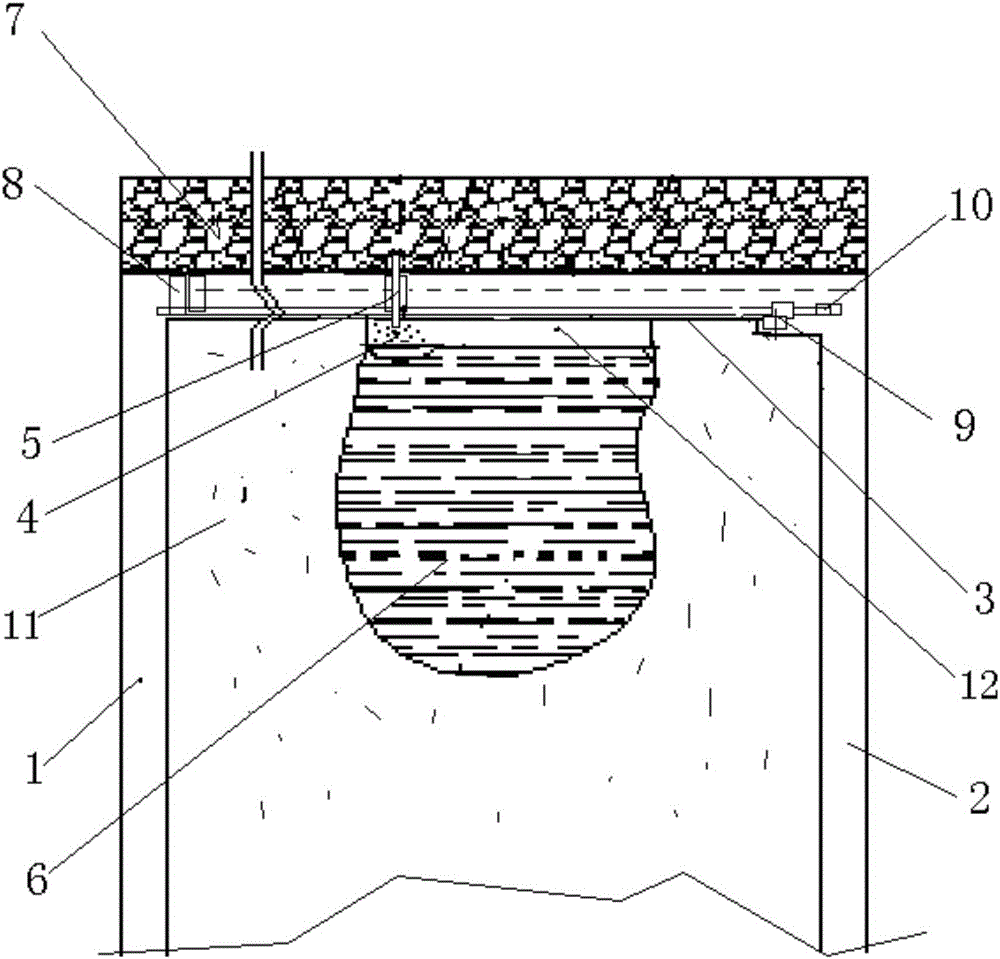

[0018] Such as figure 1 The processing method of the fully mechanized mining working face of the present invention passing through the collapse column quickly is after the coal mining face roadway system (comprising the working face transportation lane 1, the working face return air lane 2, and the coal mining face 3) is formed, firstly Geophysical prospecting / drilling methods are used to delineate the plane range of the karst subsidence column 6 in the coal seam 11 to be mined; Small hanging scraper conveyor 5 in the direction of the working face, the hanging spacing and quantity of the small hanging scraper conveyor 5 are based on the length of the collapsed column section along the direction of the working face, the type of fully mechanized hydraulic support 8 and the goaf The volume of gangue contained in the area depends on the volume of gangue, as long as the amount of gangue dropped by blasting can be transported in time; then drill holes on the karst subsidence column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com