A Wellbore Device for In-Situ Heat Injection Layered Mining Sections in Thick Oil Shale Seams

A layered mining and oil shale technology, applied in the direction of mining fluid, ground mining, earth drilling and mining, etc., can solve the problems of leakage, heat loss, deformation and damage of cement sheath, etc., to increase injection temperature, reduce thermal stress, Avoid deformation damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

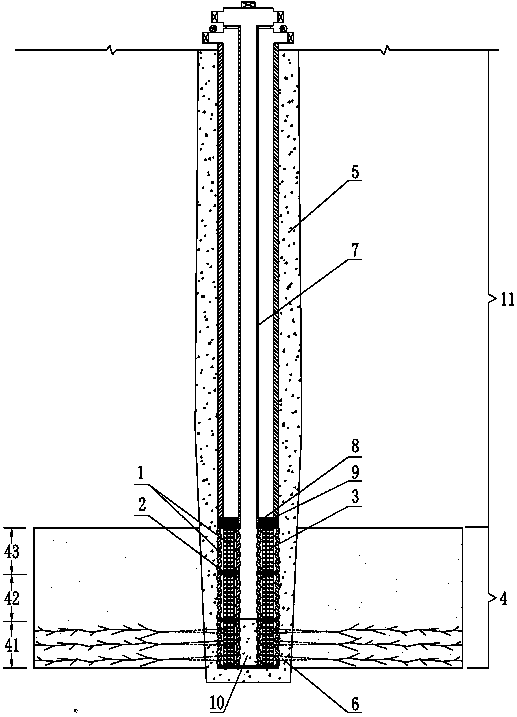

[0019] Such as figure 1 As shown, a wellbore device for the in-situ heat injection layered mining section of thick oil shale layers is formed by connecting three vacuum corrugated casings 1 with a length of 5 m. The vacuum corrugated casing 1 is composed of two outer diameters Different metal bellows (one with an outer diameter of 240mm; the other with an outer diameter of 200mm.) are set together, and then connected by an annular blind plate 2, and multi-layer heat insulation is wound in the annular gap between the two metal bellows material 3, and then vacuumize; the three vacuum corrugated casings 1 are placed in the oil shale ore section 4 in the open hole, and are respectively connected to the lower section 41 of the ore body, the middle section 42 of the ore body, and the upper section 43 of the ore body Corresponding.

Embodiment 2

[0021] Such as figure 1 As shown, a wellbore device for the in-situ heat injection layered mining section of thick oil shale layers is formed by connecting six vacuum corrugated casings 1 with a length of 20 m. The vacuum corrugated casing 1 is composed of two outer diameters Different metal bellows (one with an outer diameter of 550mm; the other with an outer diameter of 400mm.) are set together and connected by an annular blind plate 2, and multi-layer heat insulation is wound in the annular gap between the two metal bellows material 3, and then vacuumize; the 6 vacuum corrugated casings 1 are placed in the oil shale ore section 4 in the open hole, corresponding to the 6 ore body segment positions (not shown in the figure).

Embodiment 3

[0023] Such as figure 1 As shown, a wellbore device for the in-situ heat injection layered mining section of thick oil shale layers is formed by connecting 10 vacuum corrugated casings 1 with a length of 30 m. The vacuum corrugated casing 1 is composed of two outer diameters Different metal bellows (one with an outer diameter of 800mm; the other with an outer diameter of 500mm.) are set together, and then connected by an annular blind plate 2, and multi-layer heat insulation is wound in the annular gap between the two metal bellows material 3, and then vacuumize; 10 vacuum corrugated casings 1 are placed in the oil shale ore section 4 in the open hole, corresponding to the 10 ore body segment positions (not shown in the figure).

[0024] Such as figure 1 As shown, the thick oil shale target thermal injection mining area is selected, a near-horizontal single oil shale layer with a thickness of 60 m and a buried depth of 11 is 160 m. Sections are respectively the subsection 41...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com