Space module building

A technology of space and architecture, applied in the direction of architecture and building structure, can solve the problems of surplus, waste, warping and instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

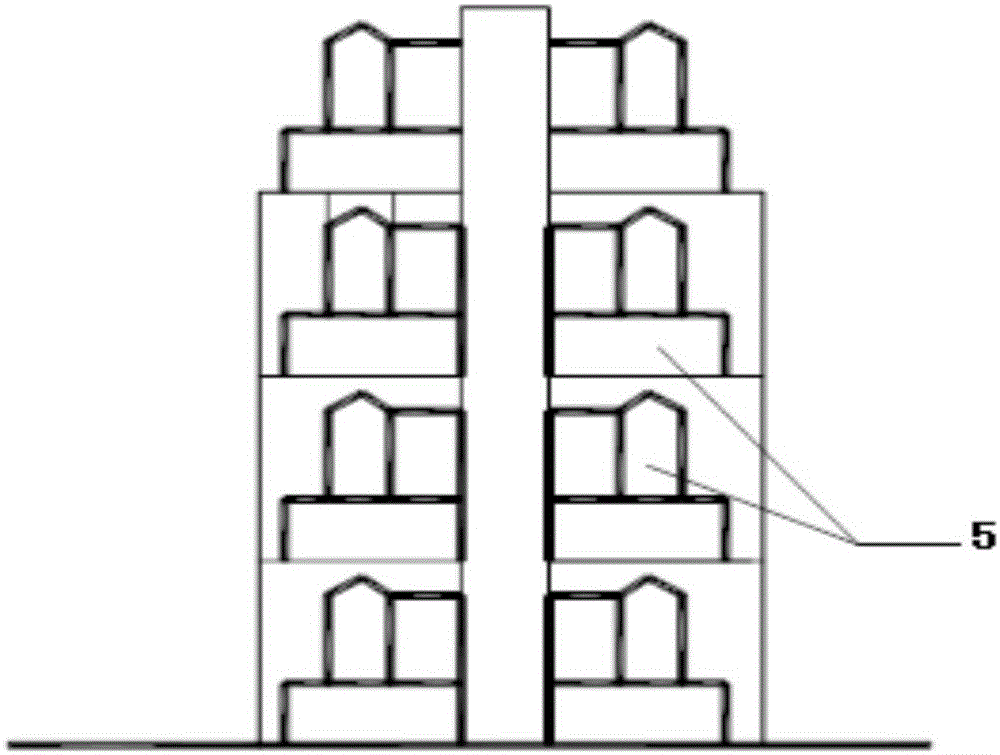

[0074] 1. If figure 1 , 2 As shown, a space module building includes a skeleton, a space module 3, and a built-in object 5; the construction method of the space module building includes the following steps:

[0075] (1) Build a basic structure such as a reinforced concrete basement under the ground;

[0076] (2) build the frame on the base structure;

[0077] (3) Build the built-in object 5 in the space module 3 .

[0078] Such as figure 1 , 3 As shown, the skeleton includes vertical resistance members 2, floor structures 4, and protrusions 9;

[0079] The floor structure, arranged horizontally, is divided into three natural-story space modules 3 vertically distributed along the skeleton in the framework; the vertical resistance member 2, arranged vertically, is divided into Distributed Spatial Module 3;

[0080] The skeleton is fixedly connected by the vertical resistance member 2 and the floor structure 4 and the horizontal resistance member serving as the beam of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com