Watermelon enzyme liquid fertilizer and preparation method thereof

A watermelon and enzyme technology, applied in the field of bio-organic fertilizer and its preparation, can solve the problems of less than 40% actual utilization rate, soil ecological environment pollution, etc., and achieve the effects of good fruit color, soil improvement, and well-developed plant root system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

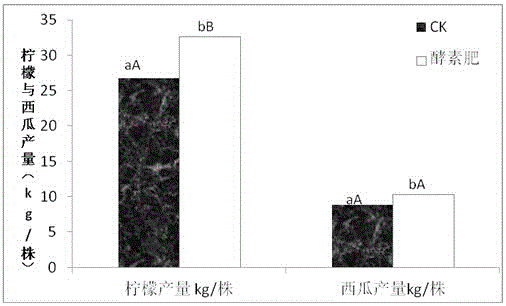

Image

Examples

Embodiment 1

[0029] Step (1), prepare raw materials according to the following components by mass percentage:

[0030] Watermelon 60%, Lemon 2%, Grapefruit 4%, Tomato 6%, Pineapple 2%, Yeast 0.5%, Urea 2%, Potassium Sulfate 1.2%, Superphosphate 6%, Zinc Sulfate 0.5%, Borax 0.5%, Brown Sugar 0.3%, 6% vegetable leaves, 6% pruned pomelo branches and tips, 3% water;

[0031] The sum of the above components is 100%;

[0032] In step (2), the fruit raw material in step (1) is pulverized into puree by a grinder, and put into a fermentation tank together with other raw materials. The fermentation tank is 200 cubic meters and the height is less than 2.0 meters;

[0033] In step (3), after covering the fermentation tank in step (2), cover it with a layer of plastic film to seal it, and carry out natural fermentation for 5 days, during which the tank cover is uncovered and stirred twice to remove the The raw material components are stirred into the bottom of the tank for uniform fermentation;

[0...

Embodiment 2

[0037] Step (1), prepare raw materials according to the following components by mass percentage:

[0038]Watermelon 50%, Lemon 1.5%, Grapefruit 2.5%, Tomato 9%, Pineapple 3%, Yeast 0.6%, Urea 1.8%, Potassium Sulfate 0.9%, Superphosphate 4.5%, Zinc Sulfate 0.3%, Borax 0.4%, Brown Sugar 0.5%, pruned lemon tree branches and tips 10%, vines 8%, water 7%;

[0039] The sum of the above components is 100%;

[0040] Step (2), the fruit raw material in step (1) is crushed into debris with a length of less than 5 cm by a grinder, and then put into a fermentation tank together with other raw materials. The fermentation tank is 180 cubic meters and the height is less than 2.0 meters;

[0041] In step (3), after covering the fermentation tank in step (2), cover it with a layer of plastic film to seal it, and carry out natural fermentation for 6 days, during which the tank cover is uncovered and stirred twice to remove the The raw material components are stirred into the bottom of the tan...

Embodiment 3

[0045] Step (1), prepare raw materials according to the following components by mass percentage:

[0046] Watermelon 55%, Lemon 1%, Grapefruit 3%, Tomato 5%, Yeast 0.8%, Urea 0.55%, Potassium Sulfate 1.5%, Superphosphate 6.5%, Zinc Sulfate 0.2%, Borax 0.1%, Molasses 0.35%, Fresh 10% vegetable leaves, 5% pruned lemon branches and tips, 5% vines, 6% water;

[0047] The sum of the above components is 100%;

[0048] Step (2), the fruit raw material in step (1) is crushed into debris with a length of less than 5 cm by a grinder, and then put into a fermentation tank together with other raw materials. The fermentation tank is 150 cubic meters and the height is less than 2.0 meters;

[0049] In step (3), after covering the fermentation tank in step (2), cover it with a layer of plastic film to seal it, and carry out natural fermentation for 5 days, during which the tank cover is uncovered and stirred twice to remove the The raw material components are stirred into the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com