Method for preparing cement from municipal solid waste incineration furnace slag

A technology for municipal solid waste and slag incineration, which is applied in cement production, etc., to reduce demand and solve outlet problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

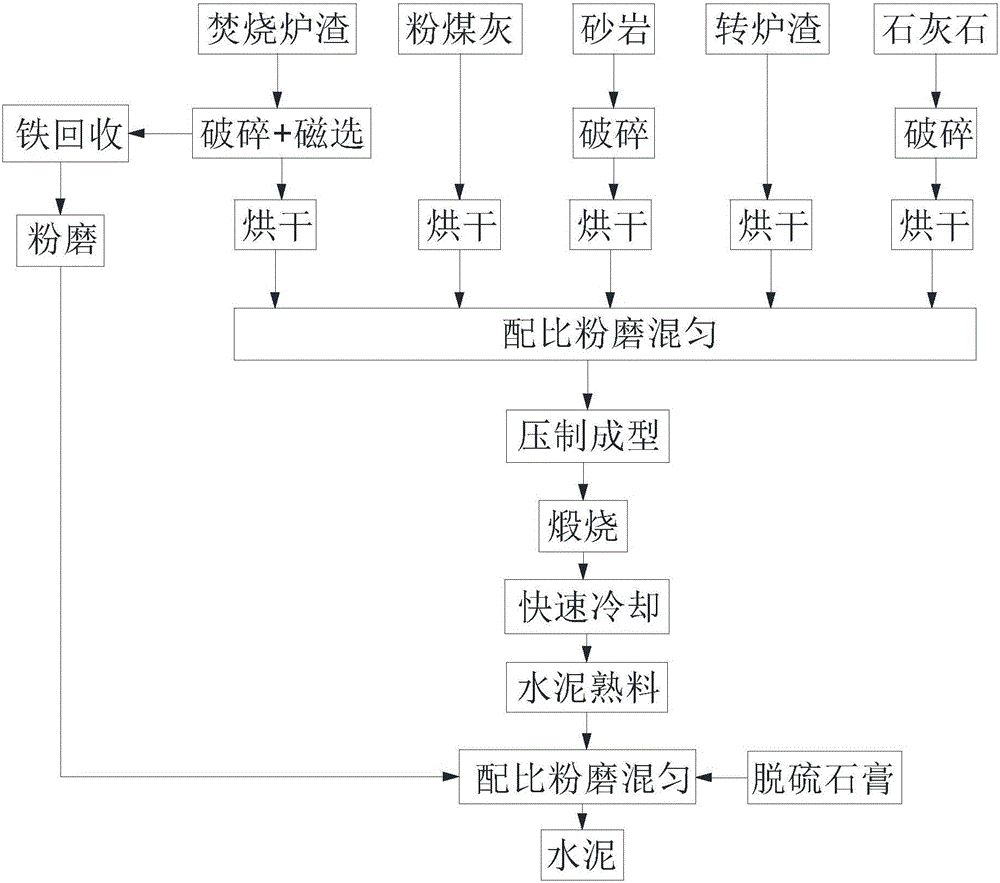

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for preparing cement from municipal solid waste incineration slag, which can be applied in a laboratory to simulate the treatment of municipal solid waste incineration slag. The prepared cement is composed of cement clinker, desulfurized gypsum and incinerator slag particles, and the cement can be obtained after grinding to a certain particle size; it includes the following steps:

[0047] S10 , performing pretreatment on the slag of municipal solid waste incineration.

[0048] In this example, the selected municipal solid waste incineration slag needs to meet the requirements in the "GB18485-2014 Domestic Waste Incineration Pollution Control Standard". , its approximate composition and content (by weight) are: SiO 2 : 48.83%; Al 2 o 3 : 10.56%; Fe 2 o 3 : 6.63%; CaO: 16.06%; MgO: 2.82%; LOI (loss on ignition, Lossonignition): 2.60%; SO 3 : 0.85%; K 2 O: 1.97%; Na 2 O: 4.84%; Cl: 1.14% and other impurities.

[0049] The pretrea...

Embodiment 2

[0062] This embodiment provides a method for preparing cement from municipal solid waste incineration slag, which can be applied in a cement kiln system, thereby realizing the industrial utilization of municipal solid waste incineration slag. The prepared cement is mixed with cement clinker, desulfurized gypsum and incinerator slag particles according to a certain ratio, and then directly ground to a certain particle size; the difference between this embodiment and embodiment 1 is that:

[0063] In step S10, the particle size of the incineration slag particles may be less than 50 mm; in step S20, the particle size of the limestone particles and sandstone particles may also be smaller than 50 mm.

[0064] Wherein, in step S40 of the present embodiment:

[0065]Enter the prepared raw meal from the suspension preheater into the cement kiln system, and burn the prepared raw meal into cement clinker; especially, the difference from the previous new dry process cement kiln is that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com