Construction of a nano-copper manganate spinel catalytic membrane reactor and its application in water treatment

A catalytic membrane reactor, nano-copper manganate technology, applied in the direction of oxidation water/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problems of catalytic activity decline, membrane fouling, unfavorable separation, etc., to prevent membrane fouling The effect formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] The construction method of the catalyst membrane reactor loaded with nano-copper manganate spinel will be described below in conjunction with specific embodiments, so as to further understand the invention. The technical solution of the present invention is not limited to the specific embodiments listed below, but also includes any combination of the specific embodiments.

specific Embodiment approach 1

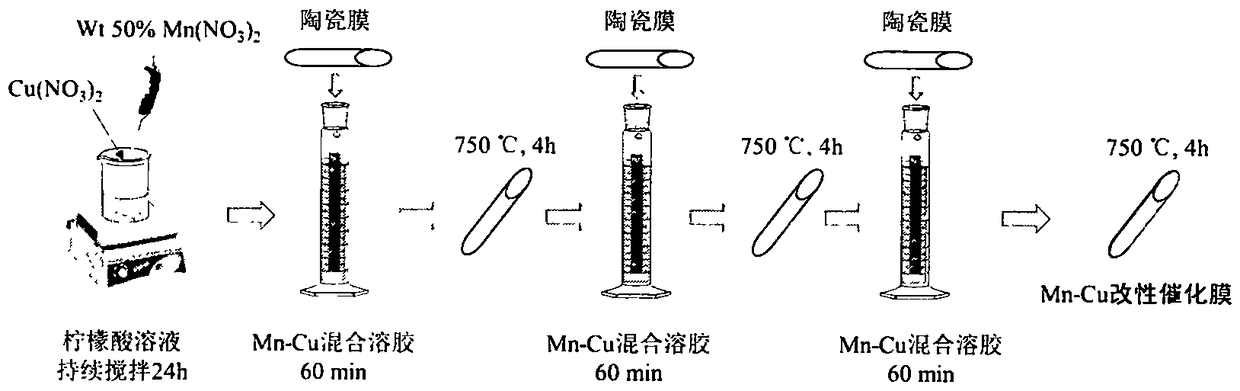

[0022] Specific implementation mode one: nano copper manganate spinel (CuMn 2 o 4 ) The construction method of catalytic membrane reactor can be realized through the following steps:

[0023] (1) Accurately weigh 40.1893g of citric acid monohydrate and dissolve it in 800mL of deionized water to completely dissolve the solute to obtain a clear solution;

[0024] (2) 10.2681gCu(NO 3 ) 2 ·3H 2 O and 10.2 mL concentration of wt.50% Mn(NO 3 ) 2 Add it to the above solution, and at the same time, the mixed solution is continuously stirred at 600rpm / min for 24 hours to completely dissolve the solute to obtain a clear solution;

[0025] (3) The above solution is heated and stirred at 150°C, and the heating is stopped after the sol is formed;

[0026] (4) Soak the ceramic membrane in the above-mentioned sol solution and let it stand for 60 minutes;

[0027] (5) Place the once-loaded ceramic membrane in a high-temperature muffle furnace for burning, the burning temperature is 75...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is that 10.2681gCu(NO 3 ) 2 ·3H 2 O can be replaced by 8.4851gCu(CH 3 COO) 2 ·H 2 O, other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com